What Is Silicone Potting Compound for Electronics

What Is Silicone Potting Compound for Electronics

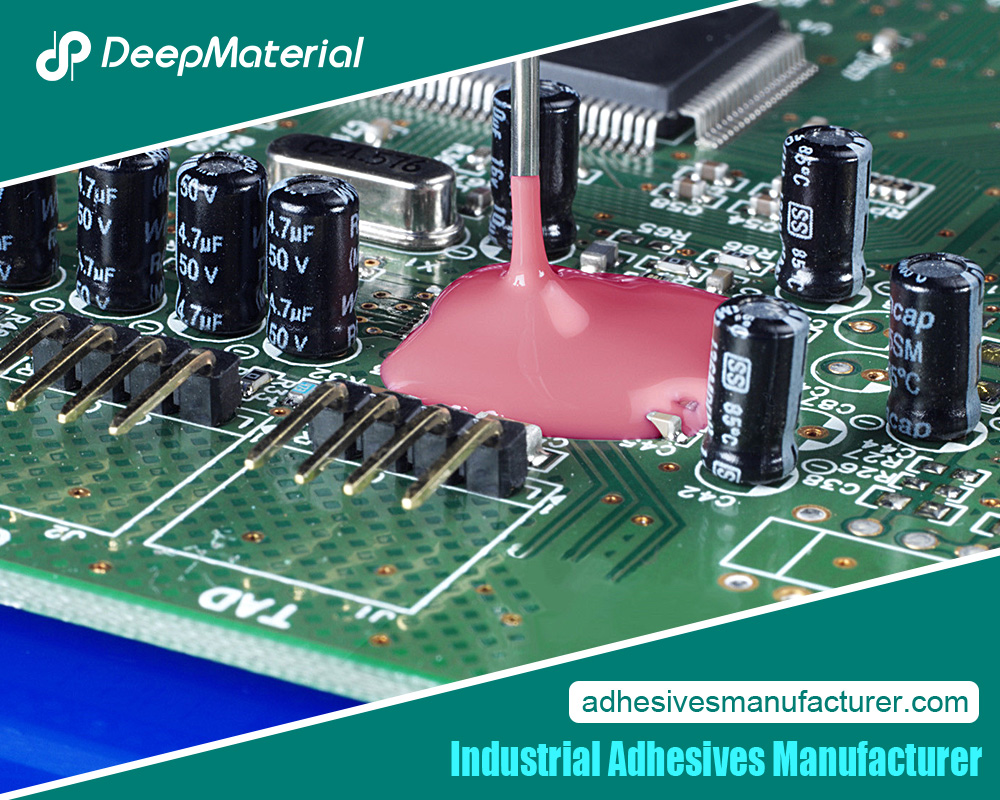

Potting compounds offer fantastic protection for electronics by encapsulating the adhesive after it has cured and formed a physical barrier similar to amber. It prevents malfunctions caused by wet weather or short-circuiting and shields from chemical attacks.

It offers resistance against mechanical shocks and vibration – particularly in sandwiched complex assemblies – while obscuring Intellectual Property Rights within high-end tech circuits.

Amazingly enough, this concept gave birth to an impressive array of sealant materials now used on the market, which can be distilled into three main categories: Epoxy Resin Compounds, Polyurethane ones, and Silicone varieties, each possessing its unique properties.

This post will limit our discussion to why silicone potting compounds have become the norm for sealing electronics.

Definition of Potting

Before we begin, let us define what potting is. Pouring a liquid compound into the device with electronic components and circuit is known as potting, and it can take place at room temperature or under heated circumstances.

This process is most commonly done by either mechanical or artificial methods to keep all the parts safe from corrosion and give them optimal performance – forming a polymer-insulating material that truly stands out! Potting can be put into two groups: Local Potting and Integral Potting.

Heat transfer is the name of the game with local potting. Connecting high-power devices to a heat sink through thermally conductive silicone rubber material helps speed up this process – sorting out any excess heat generated in no time.

Potting integral components within an electronic device ensures heat output is efficiently dissipated and removed from the surrounding environment. This technique consists of blending both elements, ridding them of air bubbles, then pouring this mixture into desired spots and curing it into a malleable, rubbery elastomer matrix. It’s all just part of the process!

Silicone potting compounds, or thermally conductive silicone potting compounds as they’re sometimes called, are well-known to those in the electronics industry. Think of it as a class of soft and pliable silicone rubber that formulates both single and two components.

In this case, though, these components provide an effective solution for different types of electronic project protection needs!

The single-component potting compound has one major perk: it can be used without worrying about defoaming, making the whole process so much simpler.

With a need to mix the liquid base adhesive and the catalyst or crosslinking agent, a two-component silicone potting compound comes in handy for insulating and encapsulating materials or airtight shock absorbers. It’s a good choice if you want things to be well sealed up with some extra cushion!

As many of us already know, thermal conductivity adhesives are typically two-part systems. Just mix them up, defoam them, and pot the thing you need so it’s all nicely vulcanized into soft rubber – not just making sure heat disperses correctly but also creating some extra shock absorption and protection from water and dust!

These days, they’re seen everywhere – from LED power supplies to batteries in electric cars or charging stations; pretty much any job where there needs to be heat dissipation plus sealing off & dampening the impact on those bad boy electronic parts.

Benefits of Using Silicone Potting Compound for Electronics

Silicone material potting adhesive excels in its modification and insulation abilities over epoxy resin. Not only is it resistant to hot and cold shocks – even the extreme temperatures of -60°C and 200°C don’t crack this wonder-adhesive; it maintains a bendy elasticity, too, helping increase moisture resistance when protecting electronic components.

After curing, the elastomer produces an impenetrable anti-impactibility as well, boasting fantastic UV protection outdoors, along with top-notch weathering and aging performance!

- After the potting is done, it’s a breeze to tidy up and take apart so that the electronics can be fixed up and any parts mended can be injected with some fresh potting.

- Silicone is a super resilient material, tackling the toughest of working conditions with an unbreakable prestige. It holds steady in even harsh conditions like ozone and UV radiation exposure, undaunted and steadfast in its dependability.

- Thanks to its durability and insulating abilities, silicone serves as a pliable shield against environmental pollution. Plus, it boasts an extensive temperature and humidity range that helps reduce the impact of shock and vibration for good!

- Silicone can provide serious security for certain electronics and delicate circuits – its structure, shape, and design ensure complete safety. That’s why you’ll see it used so frequently in electronic modules.

How to Appl Silicone Potting Compound for Electronics

- Stirring: Give A and B a good stirring until they’re properly combined – don’t let anyone else use the stir bar. You want to ensure all those little pieces of filler are evenly spread throughout the glue. Mix it up till you see everything mixed just right.

- Weighing: Taking Agent A and Agent B in the ratio of 3:10, they were thoroughly blended with vigorous stirring. The mixture bubbled like boiling oil, creating an ever-shifting landscape as if it had its own mind. At that moment, the two agents will be unified in one fragrant concoction – united by this overwhelming flux that symbolizes all things shifting and ever-changing.

- Removing Oxygen: Suck out those pesky air bubbles by vacuuming the mixture below -0.1Mpa in order to make sure your machinery is fully operational during the glue-filling process. No deoxidizing is needed!

- Pouring: Pour the adhesive into the components for a perfect encapsulation. Beforehand, keep things dry and clean – as well as wipe down surfaces of parts and mixing containers – before heating up your pouring device to 70-80 °C for 1-2 hours if you want extra reassurance.

- Curing: Curing should be done at room temperature.

Final Thoughts

Silicones’ flexibility, extreme temperature tolerance, and consistent mechanical characteristics make them a go-to for potting-sensitive electronics. They can wrap around critical components effectively – no matter what temperature! Stylish and practical, silicones offer lasting protection without ever missing a beat.

For more about a complete guide to Silicone Potting Compound for Electronics, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.