Tips for Achieving a Flexible Bond with High Strength Epoxy Adhesive Glue for Metal

Tips for Achieving a Flexible Bond with High Strength Epoxy Adhesive Glue for Metal

Getting a reliable and strong bond with high strength epoxy adhesive glue for metal is critical in many fields, from DIY crafts to professional metalworking. Knowing how to properly bond metal surfaces is key to nailing your project.

In this blog post, we’re diving into the world of high strength epoxy adhesive glue for metal. We’ll cover its characteristics, how to pick the right type, prepare surfaces, mix and apply the glue, secure and cure the bond, test its strength and flexibility, tweak as necessary, keep it strong over time, solve common problems, and ensure the bond stays tough and flexible.

Properties of High Strength Epoxy Adhesive Glue for Metal

High strength epoxy adhesive glue for metal is a specialized powerhouse designed for bonding metal. It’s made from a mix of epoxy resin and hardener that, when combined, forms a bond tough enough to handle the roughest situations. This glue is perfect for metal because it’s strong, sticks extremely well, and can handle chemical spills and temperature swings without a sweat.

One big plus of this glue is its high tensile strength, meaning it can take a lot of pull and pressure without giving up. It bonds metal so well, they might as well be family.

It’s also great at holding its own against chemicals and temperature changes. Whether it’s a scorching summer day or a freezing winter night, this glue won’t crack under the pressure. This feature is especially valuable in industrial environments where harsh conditions are all in a day’s work.

Lastly, this glue can handle heavy loads and vibrations without budging. This is crucial for projects involving heavy machinery or equipment, ensuring everything stays exactly where it should, even under intense stress.

Choosing the Right Type of Epoxy Adhesive Glue for Metal

When picking the perfect epoxy adhesive glue for your metal project, you’ve got to weigh a few things: what type of metal are you sticking together? What wild weather will it face? How strong and flexible does the bond need to be? There’s a whole lineup of epoxies out there—fast-curing, high-temperature resistant, and even flexible types. Get to know your project’s needs to snag the best fit.

The following can help you achieve a flexible bond while using epoxy glue.

Preparing the Metal Surface for Bonding

Getting the metal surface ready is a big deal if you want a strong, flexible bond. Make sure the surfaces are spotless, dry, and stripped of any oil, grease, rust, or old paint. You can clean up with solvents, sandpaper, or wire brushes. A little roughening up by sanding or scoring helps the glue grab on better, leading to a tougher bond.

Mixing the Epoxy Adhesive Glue Correctly

Mixing your epoxy right is crucial. You’ve got to blend the resin and hardener in just the right ratio, as the directions say. Mix them up in a clean container, stirring until they’re totally combined. Be careful not to mix too little or too much. Getting this step wrong could mess with the curing time and the strength of your bond.

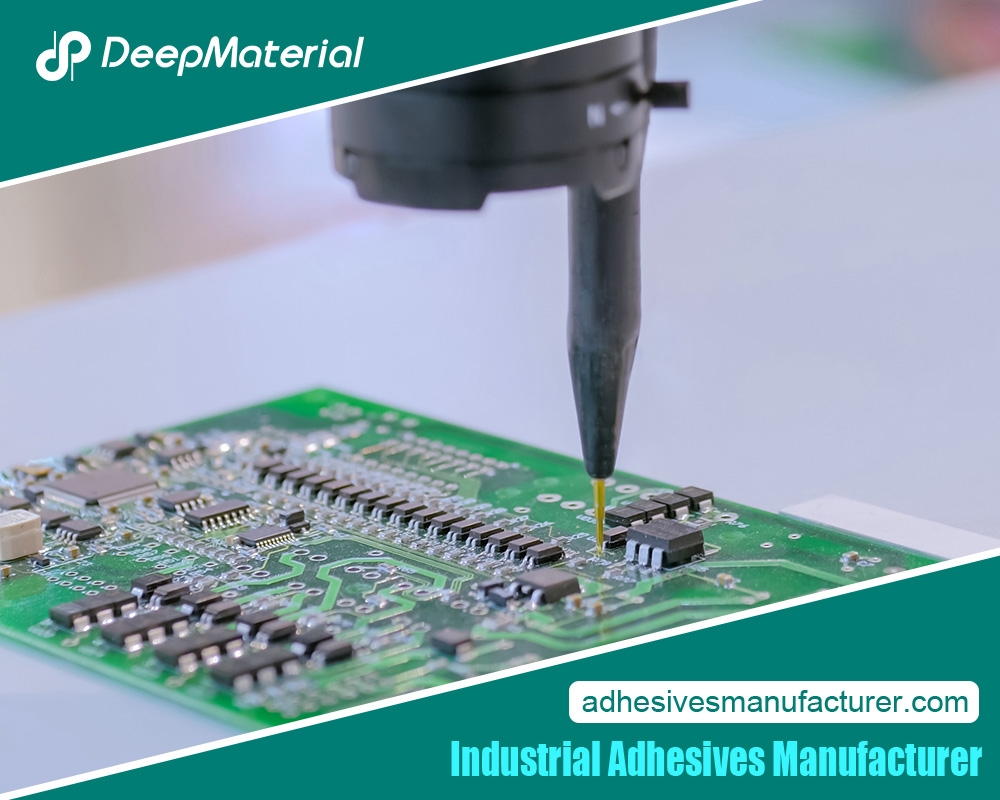

Applying the Epoxy Adhesive Glue to the Metal Surface

Applying the glue correctly is key. Use a brush, spatula, or whatever tool fits the size and shape of the metal pieces. Spread the glue evenly across both surfaces, covering them completely without leaving gaps or trapping air bubbles. Follow the directions for how thick the glue layer should be. Putting on too much or too little could weaken the bond, so aim for just right.

Using Clamps or Other Tools to Secure the Bond

Sometimes, you might need to bring in the big guns like clamps or other tools to hold everything together while your epoxy adhesive glue for metal does its magic. This is especially true for bigger or heavier metal pieces that need a bit of extra support as they cure. Apply clamps evenly and with just the right amount of pressure to make sure the bond is consistent. Too much pressure, though, could push out all your glue or even warp your metal, which is definitely not what you want.

Allowing Sufficient Time for the Epoxy Adhesive Glue to Cure

Patience is a virtue, especially when it comes to letting your epoxy adhesive glue for metal cure. The time it takes to set can vary based on the type of glue, the current temperature, humidity, and how thickly you’ve applied the adhesive. Always check the manufacturer’s guidelines for specific times and conditions. Rushing this process might leave you with a bond that’s about as strong as a limp handshake, so give it the time it needs to reach its full strength.

Checking the Bond Strength and Flexibility

Once your epoxy adhesive glue for metal has fully cured, it’s crucial to check how strong and flexible the bond is before you move on to anything else. Test it by applying some controlled force to see how it holds up. A good bond should handle this pressure without showing any signs of cracking or coming apart. Flexibility is also key, especially in projects where the bonded parts might move or shake a bit.

Making Adjustments to the Bond as Needed

If the bond isn’t quite up to par in strength or flexibility, don’t fret; you can still fix it. You might need to apply more glue to weak spots, add more clamps, or even switch to a different type of epoxy that’s better suited for your project’s specific needs. It’s important to evaluate the bond thoroughly and tweak your approach based on how it’s holding up.

Maintaining the Bond Over Time

To keep the bond in top shape over time, stick to a good maintenance routine. Regularly check the bonded areas for any signs of wear like cracks, corrosion, or a bond that’s starting to loosen. If you spot any issues, address them quickly—reapply the glue or make necessary repairs. Also, keeping the stress low on these areas will help extend the bond’s life.

Troubleshooting Common Issues with Epoxy Adhesive Glue for Metal Bonds

Even with the best preparation and application, sometimes things don’t go as planned with metal bonds. You might run into problems like poor adhesion, weak bond strength, not enough flexibility, or the glue not curing right. To fix these, start by figuring out what went wrong. Revisit how you prepared the surface, check your mix ratio, or try a different epoxy. If you’re stuck, it might be time to consult a pro.

Final Thoughts

Mastering the use of high strength epoxy adhesive glue for metal takes understanding its properties and applying it correctly. Choose the right glue, prepare the surfaces well, mix and apply the glue as instructed, and ensure everything is secure while curing. After curing, test the bond’s strength and flexibility, adjust as necessary, and keep up with maintenance. Troubleshoot any issues by going back to the basics or getting expert help. With careful attention and proper techniques, you can achieve strong and lasting bonds in your metalworking projects.

For more about the tips for achieving a flexible bond with high strength epoxy adhesive glue for metal, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.