Thermal Potting Compound

Thermal Potting Compound

In the era of rapid technological development today, the performance and reliability of electronic devices have become the focus of people’s attention. To ensure the stable operation of electronic components in complex working environments, various advanced materials and technologies have emerged. Among them, Thermal Potting Compound, as an important electronic packaging material, plays an indispensable role.

Definition and Characteristics of Thermal Potting Compound

Definition and Characteristics of Thermal Potting Compound

Thermal Potting Compound is a polymer composite material with good thermal conductivity and insulation performance. It is usually prepared through a special process by using basic materials such as organosilicon, epoxy resin, polyurethane, adding thermal conductive fillers (such as alumina, boron nitride, magnesium oxide, etc.) and various additives (such as curing agents, accelerators, toughening agents, etc.).

Its main characteristics include:

- Excellent thermal conductivity: It can effectively conduct the heat generated by electronic components, reduce the operating temperature of the components, and improve their stability and service life.

- Good insulation performance: It can provide reliable electrical insulation protection for electronic components and prevent short circuits and leakage faults.

- Outstanding chemical corrosion resistance: It can resist the erosion of various chemical substances and ensure long-term stable operation in harsh environments.

- Low stress: The stress generated during the curing process is small and will not cause mechanical damage to electronic components.

- Customizability: The formula and performance parameters can be adjusted according to different application requirements to meet specific requirements.

Classification of Thermal Potting Compound

According to different basic materials, Thermal Potting Compound can mainly be classified into the following categories:

- Silicone-based thermal potting compound

- It has excellent high-temperature resistance and can be used for a long time in the temperature range of -50°C to 200°C.

- Good flexibility and weather resistance, and can adapt to the working requirements of electronic devices in different environments.

- However, the price is relatively high.

- Epoxy resin-based thermal potting compound

- It has high mechanical strength and bonding performance, and can provide good fixation and protection for electronic components.

- The curing speed is fast and the production efficiency is high.

- But the temperature resistance performance is relatively low, generally between -40°C and 150°C.

- Polyurethane-based thermal potting compound

- Good flexibility and strong impact resistance.

- It has good adhesion to various substrates.

- However, its weather resistance and chemical corrosion resistance are relatively weak.

Working Principle of Thermal Potting Compound

The thermal conductivity of Thermal Potting Compound mainly depends on the type, content and distribution of the thermal conductive fillers inside. The thermal conductive fillers form thermal conductive paths in the glue, enabling rapid heat transfer.

When electronic components are working and generating heat, the heat is first transferred to the potting compound through the contact interface between the components and the potting compound. Then, the heat in the potting compound rapidly diffuses along the thermal conductive paths and is finally transferred to the external environment, thereby achieving heat dissipation and protection for the electronic components.

At the same time, the insulation performance of Thermal Potting Compound can effectively prevent abnormal current flow between electronic components and ensure the normal operation of the circuit.

Application Fields of Thermal Potting Compound

Due to its excellent performance, Thermal Potting Compound has been widely used in many fields:

- Electronic and Electrical Industry

- Power Modules: Such as switching power supplies, chargers, adapters, etc. The potting compound can effectively improve the stability and reliability of the power supply and extend its service life.

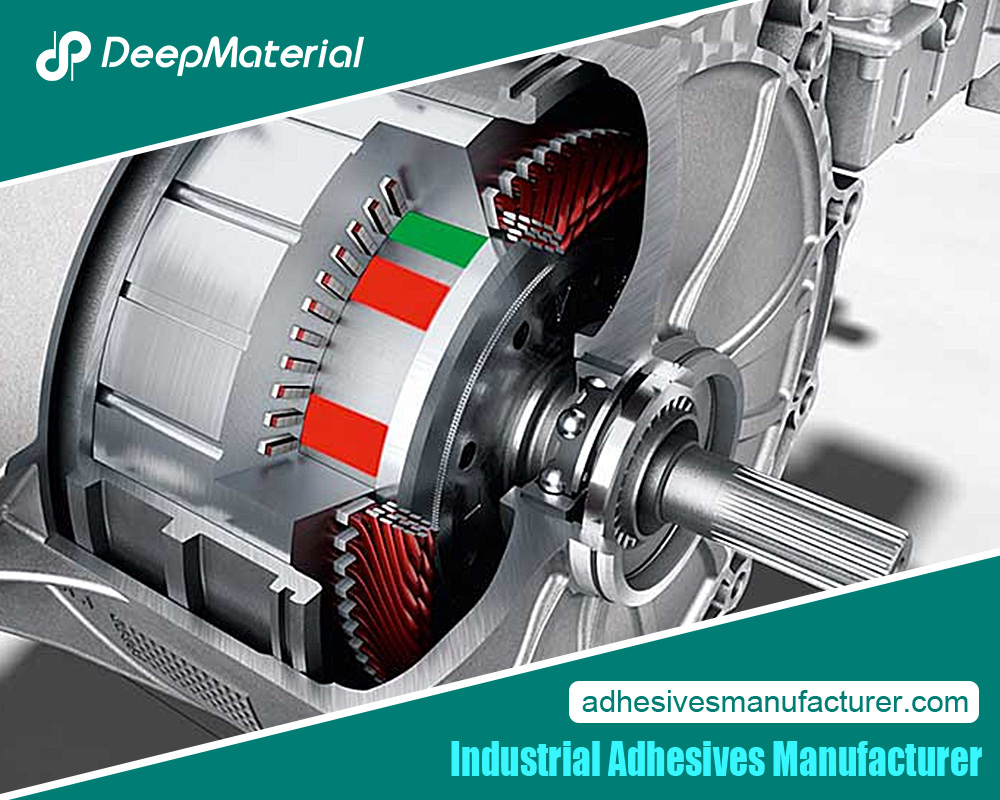

- Motor Controllers: Provide heat dissipation and insulation protection for the electronic components in the motor controller to ensure the normal operation of the motor.

- Sensors: Protect sensors from external environmental interference and improve measurement accuracy and stability.

- Integrated Circuit (IC) Packaging: Improve the heat dissipation performance of IC, reduce the thermal resistance, and enhance reliability.

- New Energy Field

- Solar Photovoltaic Modules: The potting compound can protect photovoltaic cells and junction boxes and improve the weather resistance and service life of the modules.

- Electric Vehicle Battery Packs: Encapsulate battery cells and electronic components in the battery pack to play the role of heat dissipation, insulation and protection, and ensure the safety performance of the battery pack.

- Communication Industry

- Base Station Equipment: Provide heat dissipation and protection for the RF modules, power amplifiers and other components in the base station to ensure the stable transmission of communication signals.

- Optical Communication Equipment: Protect sensitive components such as optical modules and transceivers to improve the reliability and stability of the equipment.

- Aerospace and Military Field

- Electronic equipment in spacecraft such as satellites and missiles: In extreme temperature, pressure and radiation environments, the potting compound can provide reliable protection for electronic components to ensure the normal operation of spacecraft.

- Military equipment: Such as radars and navigation systems, the application of potting compound can improve the anti-shock, anti-vibration and anti-electromagnetic interference capabilities of the equipment.

Selection and Use of Thermal Potting Compound

When selecting Thermal Potting Compound, the following factors need to be considered:

- Thermal conductivity performance: Select the potting compound with the appropriate thermal conductivity coefficient according to the heating power and heat dissipation requirements of the electronic components.

- Insulation performance: Ensure that the potting compound has sufficient insulation strength according to the working voltage and insulation requirements of the circuit.

- Operating temperature range: Select the potting compound that can work stably within the corresponding temperature range according to the working environment temperature of the electronic device.

- Curing conditions: Consider the curing time, curing temperature and curing method of the potting compound to adapt to the requirements of the production process.

- Mechanical properties: Select the potting compound with appropriate mechanical strength and flexibility according to the installation method and stress situation of the electronic components.

When using Thermal Potting Compound, the following steps need to be followed:

- Surface treatment: Clean, dry and degrease the surfaces of electronic components and packaging cavities to improve the adhesion of the potting compound.

- Mixing and stirring: Fully mix and stir the components A and B of the potting compound according to the requirements of the product manual.

- Potting operation: Slowly inject the mixed potting compound into the packaging cavity to avoid generating bubbles.

- Curing treatment: Perform heating or normal temperature curing according to the curing conditions of the potting compound.

- Inspection and acceptance: After curing, conduct appearance inspection, thermal conductivity test and insulation performance test on the potted products to ensure that the product quality meets the requirements.

Market Status and Development Trend of Thermal Potting Compound

With the continuous miniaturization, integration and high performance of electronic devices, the demand for Thermal Potting Compound is also continuously increasing. Currently, the global market for thermal potting compound presents the following characteristics:

- The market size is constantly expanding: According to market research institutions’ predictions, the global market for thermal potting compound will maintain a high growth rate in the next few years.

- Technological innovation is continuous: Major manufacturers have increased their R & D investment and continuously launched thermal potting compound products with better performance, more environmentally friendly and easier to use.

- Expansion of application fields: In addition to traditional fields such as electronic appliances and new energy, the application of thermal potting compound in emerging fields such as 5G communication, artificial intelligence and the Internet of Things is also gradually increasing.

In the future, the development trend of Thermal Potting Compound mainly includes:

- Higher thermal conductivity: With the continuous increase of the heating power of electronic components, higher requirements are put forward for the thermal conductivity of the potting compound, and the thermal conductivity coefficient will continue to increase.

- Better comprehensive performance: On the basis of ensuring the thermal conductivity and insulation performance, the potting compound will have better comprehensive performance such as weather resistance, chemical corrosion resistance and mechanical properties.

- Environmental protection and sustainable development: With the enhancement of environmental awareness, green and environmentally friendly thermal potting compound will become the mainstream of the market, and products with no solvents and low volatile organic compounds (VOC) will be more favored.

- Intelligence and customization: With the advancement of Industry 4.0, the production and application of thermal potting compound will be more intelligent and customized to meet the individualized needs of different customers.

Conclusion

Conclusion

Thermal Potting Compound, as an important electronic packaging material, plays a key role in ensuring the performance and reliability of electronic devices. With the continuous progress of technology and the continuous change of market demand, the technology of thermal potting compound will continue to innovate and the application fields will continue to expand. It is believed that in the future, Thermal Potting Compound will make greater contributions to the development of the electronic industry.

For more about a complete guide to thermal potting compound, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.