The Ultimate Guide to Using 2 Part Epoxy for Metal: A Comprehensive Overview

The Ultimate Guide to Using 2 Part Epoxy for Metal: A Comprehensive Overview

When it comes to bonding, repairing, or protecting metal surfaces, few materials offer the versatility and strength of 2 Part epoxy. This adhesive, known for its robust bonding capabilities, is a go-to solution for professionals and DIY enthusiasts. Whether working on industrial machinery, automotive repairs, or simple home projects, 2 Part epoxy for metal can be an essential tool in your arsenal. This article explores everything you need to know about 2 Part epoxy for metal, from its composition to its applications, benefits, and tips for successful use.

What is 2 Part Epoxy?

2 Part epoxy consists of two components: a resin and a hardener. When these two components are mixed, they undergo a chemical reaction that results in a robust and durable bond. This bond can be used on various materials but is particularly effective on metal surfaces.

- Resin: The resin is the adhesive component that forms the bulk of the mixture. It provides the glue-like substance that bonds materials together.

- Hardener: The hardener triggers the chemical reaction that causes the resin to cure and harden, creating a robust and lasting bond.

Why Use 2 Part Epoxy for Metal?

Superior Bond Strength

- One of the most compelling reasons to use 2 Part epoxy for metal is its exceptional bond strength. Unlike other adhesives that may weaken over time or under stress, epoxy bonds are known for their long-lasting durability.

Versatility

- 2 Part epoxy is effective on metal and can bond a wide range of materials, including plastic, wood, and glass. It makes it a versatile choice for various projects.

Heat and Chemical Resistance

- Metals must often withstand harsh conditions, such as high temperatures or chemical exposure. 2 Part epoxy is formulated to resist these elements, ensuring the bond remains strong under extreme conditions.

Applications of 2 Part Epoxy for Metal

Applications of 2 Part Epoxy for Metal

Automotive Repairs

- 2 Part epoxy is commonly used in automotive repairs, from fixing cracks in engine parts to bonding metal panels. It is beneficial for repairing vehicle aluminum, steel, and other metal components.

Industrial Machinery

- Machinery often experiences wear and tear in industrial settings. Two-part epoxy can be used to repair or maintain these machines, extending their lifespan and ensuring they operate efficiently.

Home Improvement Projects

- For DIY enthusiasts, 2 Part epoxy offers a reliable solution for various home improvement projects. Whether you are repairing metal fixtures, creating custom metal art, or fixing appliances, epoxy can provide the strength and durability needed.

How to Choose the Right 2 Part Epoxy for Metal

Consider the Metal Type

- Different metals may require different types of epoxy. For example, aluminum may need a different formulation than steel. Always check the manufacturer’s recommendations to ensure compatibility.

Cure Time

- Cure time can vary depending on the specific epoxy product. Some epoxies cure quickly, while others may take several hours or days. When selecting an epoxy, consider the time you have available and the requirements of your project.

Temperature Resistance

- If your project involves exposure to high temperatures, choose an epoxy specifically formulated for heat resistance. It will ensure that the bond remains strong even under extreme conditions.

Chemical Resistance

- For projects involving chemical exposure, selecting an epoxy that can withstand those conditions without degrading is essential.

Step-by-Step Guide to Using 2 Part Epoxy for Metal

- Prepare the Surface

- Proper surface preparation is crucial for a strong bond. Clean the metal surface thoroughly to remove dirt, grease, or rust. Sand the surface lightly to create a rough texture, which helps the epoxy adhere better.

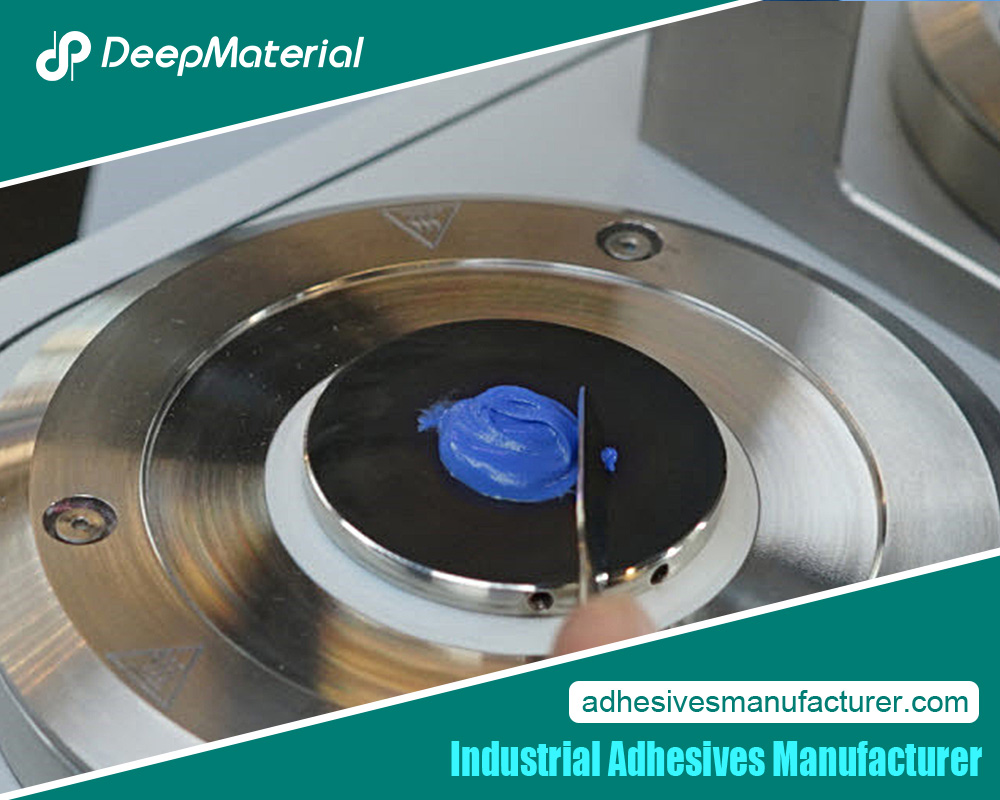

- Mix the Epoxy

- Follow the manufacturer’s instructions to mix the resin and hardener in the correct proportions. Use a clean, disposable container and mix the components thoroughly to ensure an even consistency.

- Apply the Epoxy

- Apply the mixed epoxy to the metal surface using a brush or spatula. Be sure to spread it evenly for a consistent bond. If you are bonding two pieces of metal together, apply epoxy to both surfaces before pressing them together.

- Clamp the Pieces Together

- If bonding two metal pieces, use clamps to hold them together while the epoxy cures. It ensures the bond remains strong and the pieces do not shift during curing.

- Allow Time for Curing

- Follow the product’s recommended curing time before handling the bonded pieces. Curing times can vary, so be sure to read the instructions carefully.

Tips for Successful Epoxy Application

- Work in a Well-Ventilated Area: Epoxy fumes can be harmful, so always work in a well-ventilated area or wear a mask to protect yourself.

- Use Protective Gear: Wear gloves and protective eyewear to avoid skin and eye contact with the epoxy.

- Measure Accurately:Incorrect resin-to-hardener ratios can result in weak bonds. Always measure carefully to ensure a robust and durable bond.

- Avoid Excessive Mixing: Over-mixing can introduce air bubbles into the epoxy, weakening the bond. Mix the components just enough to achieve a uniform consistency.

Benefits of Using 2 Part Epoxy for Metal

Long-Lasting Durability

- Epoxy bonds are known for their longevity, making them ideal for applications requiring a lasting bond. Once cured, the bond resists wear and tear, ensuring it holds up over time.

Strong Adhesion

- 2 Part epoxy offers superior adhesion compared to other adhesives. It can bond metal to metal or other materials with exceptional strength, making it a reliable choice for high-stress applications.

Resistance to Environmental Factors

- Epoxy resists environmental factors such as moisture, temperature fluctuations, and chemicals. It is suitable for indoor and outdoor use and harsh industrial environments.

Cost-Effective

- While 2 Part epoxy may be more expensive than other adhesives, its durability and strength make it a cost-effective solution in the long run. Repairing or bonding metal components effectively can save money on replacements.

Common Mistakes to Avoid

Incorrect Mixing Ratios

- One of the most common mistakes when using 2 Part epoxy is mixing the resin and hardener in incorrect ratios. It can result in a bond either too weak or too brittle.

Inadequate Surface Preparation

- Cleaning and preparing the metal surface can help avoid adhesion. Always ensure that the surface is free of contaminants before applying epoxy.

Rushing the Curing Process

- Allowing the epoxy to cure is essential for achieving a solid bond. Rushing this process can weaken the bond and lead to failure.

Frequently Asked Questions

How long does 2 Part epoxy take to cure?

- Cure times vary depending on the product, but most 2 Part epoxies take 24 to 72 hours to cure fully. Some fast-curing epoxies may harden within a few hours.

Can 2 Part epoxy be sanded or painted?

- Yes, once fully cured, 2 Part epoxy can be sanded and painted. It makes it an excellent choice for applications where the bond will be visible and needs to be finished.

Is 2 Part epoxy waterproof?

- Most 2 Part epoxies are waterproof once cured, making them suitable for applications exposed to moisture.

Conclusion

Conclusion

2 Part epoxy for metal is a versatile and powerful adhesive that offers exceptional bond strength, durability, and resistance to environmental factors. Whether you are working on automotive repairs, industrial machinery, or home improvement projects, 2 Part epoxy can provide a reliable and long-lasting solution. You can achieve professional-quality project results by understanding how to choose, mix, and apply epoxy correctly. Remember to take your time, follow the instructions carefully, and avoid common mistakes to ensure a successful application.

For more about the ultimate guide to using 2 part epoxy for metal: a comprehensive overview, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.