The Power of Industrial Strength Epoxy Adhesive: Applications, Benefits, and Best Practices

The Power of Industrial Strength Epoxy Adhesive: Applications, Benefits, and Best Practices

Industrial strength epoxy adhesive is a robust solution for many adhesive applications. From automotive repairs to large-scale industrial projects, this adhesive is prized for its exceptional bonding capabilities, resistance to environmental stressors, and versatility. Whether you’re a professional needing a reliable adhesive for heavy-duty tasks or a DIY enthusiast tackling complex projects, understanding the properties, applications, and proper usage of industrial strength epoxy adhesive can significantly enhance your work’s durability and effectiveness.

What is Industrial Strength Epoxy Adhesive?

Composition and Properties

Industrial strength epoxy adhesive is a two-part adhesive comprising resin and a hardener. When these two components are mixed, they undergo a chemical reaction that creates a strong, durable bond capable of withstanding significant stress. This adhesive is known for its:

- High bond strength: Capable of adhering to various surfaces, including metal, plastic, wood, and ceramics.

- Chemical resistance: It is resistant to many chemicals, including acids, solvents, and oils, making it ideal for industrial environments.

- Temperature tolerance: Withstands extreme high and low without losing its bonding properties.

- Durability: Offers long-lasting adhesion that can endure environmental factors like moisture and UV exposure.

Types of Epoxy Adhesives

There are various types of epoxy adhesives, each designed for specific applications:

- One-component epoxy:Pre-mixed and ready to use, ideal for more straightforward tasks requiring quick application.

- Two-component epoxy: Requires mixing of resin and hardener, providing stronger bonds suitable for heavy-duty industrial use.

- Heat-cured epoxy: Requires heat to cure and is used in high-performance applications such as aerospace or automotive industries.

- UV-cured epoxy: Cures when exposed to UV light, often used in electronics and optical devices.

Applications of Industrial Strength Epoxy Adhesive

Applications of Industrial Strength Epoxy Adhesive

Automotive and Aerospace Industries

In the automotive and aerospace industries, industrial strength epoxy adhesives are crucial for ensuring the integrity and safety of vehicles and aircraft. They are used for:

- Bonding structural components: Bonding structural components, Such as frames, panels, and engine parts.

- Sealing and protecting:Against corrosion, moisture, and other environmental factors.

- Repairing and reinforcing: Damaged or weakened parts to restore their strength and functionality.

Construction and Building Maintenance

Epoxy adhesives play a vital role in construction, where their strength and durability are essential for long-term structural integrity. Common uses include:

- Concrete repair: Filling cracks and bonding concrete elements, providing a seamless and robust finish.

- Anchor bonding: Securing bolts and rebar into concrete or masonry, ensuring a stable and lasting connection.

- Floor coatings: Offering a durable, chemical-resistant surface ideal for industrial and commercial spaces.

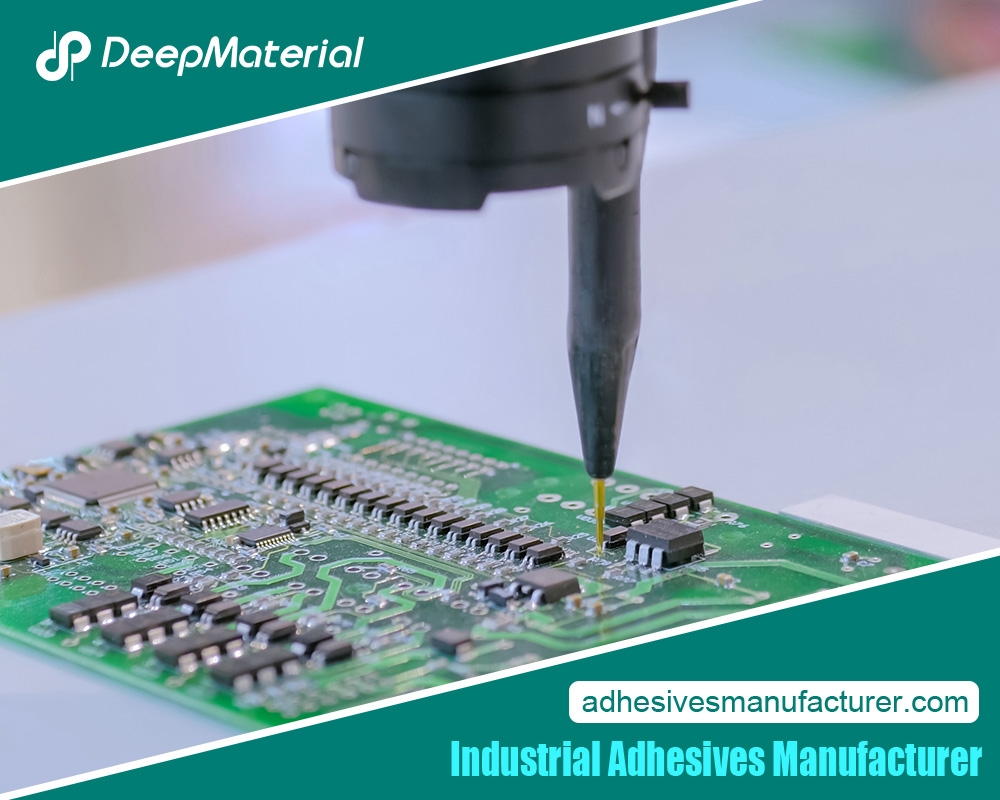

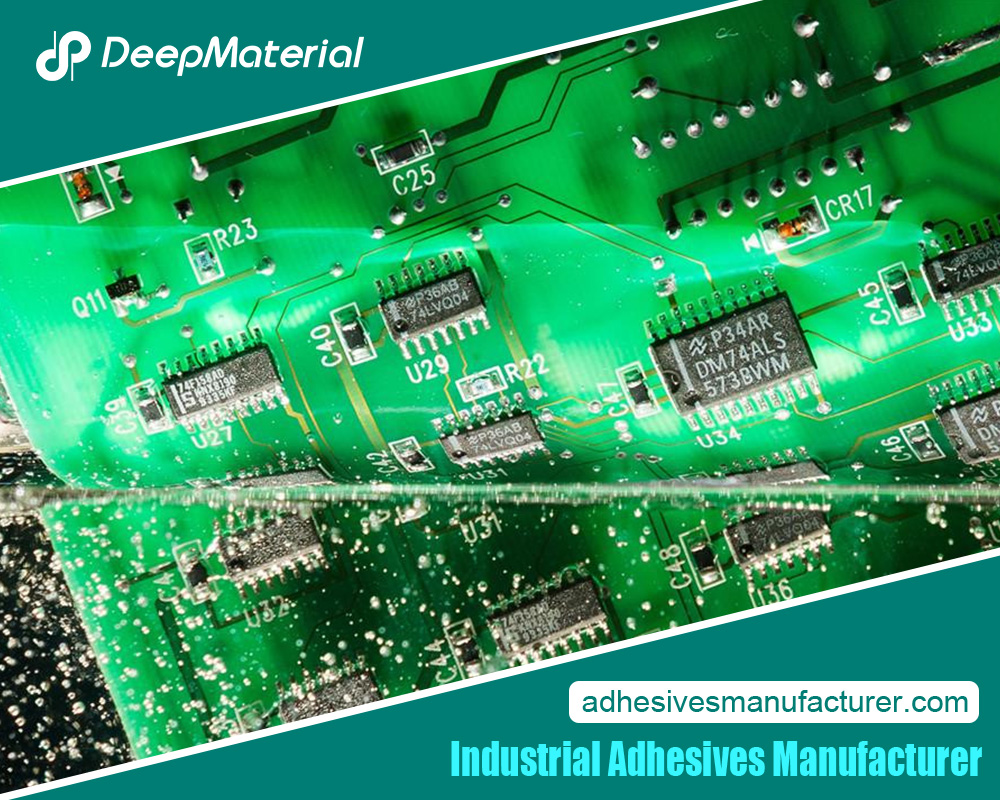

Electronics and Electrical Engineering

In electronics, the precision and reliability of epoxy adhesives make them indispensable for:

- Component encapsulation:Protecting sensitive electronic components from moisture, dust, and mechanical damage.

- Printed circuit boards (PCBs): Securing components and providing insulation, ensuring the stability and performance of electronic devices.

- Heat dissipation: Some epoxy formulations are designed to dissipate heat, which is crucial for high-performance electronic applications.

Marine and Offshore Applications

The harsh conditions of marine environments demand adhesives that can withstand constant exposure to water, salt, and temperature fluctuations. Industrial strength epoxy adhesives are used for:

- Boat repairs: Bonding hulls, decks, and other structural elements.

- Sealing leaks: Providing watertight seals in both above and below waterline applications.

- Corrosion protection: Coating metal parts to prevent rust and degradation from saltwater exposure.

Benefits of Using Industrial Strength Epoxy Adhesive

Unmatched Bonding Strength

- One of the primary reasons professionals choose industrial strength epoxy adhesive is its unparalleled bonding strength. It can securely bond dissimilar materials, making it versatile for various industrial applications.

Resistance to Environmental Stressors

- Epoxy adhesives resist environmental stressors such as moisture, heat, and chemicals, making them ideal for applications in harsh environments where other adhesives might fail.

Long-lasting Durability

- The durability of industrial strength epoxy adhesive ensures that bonds remain secure over long periods, even under constant stress. This longevity reduces the need for frequent repairs or replacements, saving time and costs.

Versatility Across Industries

- Epoxy adhesives’ versatility allows them to be used across multiple industries, from construction and automotive to electronics and marine applications. Their ability to adhere to various materials further enhances their utility.

Best Practices for Using Industrial Strength Epoxy Adhesive

Surface Preparation

For optimal bonding, proper surface preparation is crucial:

- Cleaning: Ensure surfaces are free from dust, oil, and other contaminants.

- Sanding: Roughen smooth surfaces to enhance adhesion.

- Drying: Make sure surfaces are dry to prevent weakening the bond.

Mixing and Application

When using two-part epoxy adhesives, accurate mixing is essential:

- Follow instructions: Adhere strictly to the manufacturer’s instructions for mixing ratios.

- Mix thoroughly: Ensure the resin and hardener are fully blended for a uniform mixture.

- Apply evenly:Spread the adhesive evenly on the surface to avoid weak spots.

Curing Process

The curing process is critical to achieving maximum bond strength:

- Temperature control: Maintain the recommended temperature during curing for best results.

- Time considerations: Allow sufficient time for the adhesive to cure fully before subjecting it to stress.

- Post-curing:In some cases, additional curing at elevated temperatures may be required to enhance bond strength.

Common Challenges and How to Overcome Them

Incomplete Curing

Only complete curing can maintain the bond strength of epoxy adhesives. To prevent this:

- Ensure proper mixing: Follow the recommended ratios and mix thoroughly.

- Maintain the right temperature: Keep the work area at the required temperature during curing.

- Allow sufficient curing time: Be patient and give the adhesive ample time to cure fully.

Bond Failure

Bond failure can occur due to improper surface preparation or application. To avoid this:

- Prepare surfaces meticulously: Clean, sand, and dry surfaces before applying the adhesive.

- Apply the adhesive correctly:Use the right amount and spread it evenly across the bonding surface.

Environmental Factors

Environmental factors such as humidity, temperature, and chemical exposure can affect the performance of epoxy adhesives. To mitigate these effects:

- Choose the suitable adhesive: Select an epoxy adhesive formulated for your specific environmental conditions.

- Control the environment: Work in a controlled environment or take precautions to protect the adhesive during application and curing.

Safety Considerations When Using Industrial Strength Epoxy Adhesive

Personal Protective Equipment (PPE)

When working with industrial strength epoxy adhesives, safety is paramount:

- Wear gloves: Protect your skin from contact with the adhesive.

- Use safety goggles: Prevent adhesive splashes from reaching your eyes.

- Ensure proper ventilation:Work in a well-ventilated area to avoid inhaling fumes.

Handling and Storage

Proper handling and storage of epoxy adhesives are crucial for safety and product longevity:

- Store properly: Keep the adhesive in a cool, dry place away from direct sunlight and heat sources.

- Handle with care: Avoid spilling or splashing the adhesive, and clean up any spills immediately.

Disposal and Environmental Impact

Epoxy adhesives can be hazardous to the environment if not disposed of properly:

- Follow disposal guidelines: Adhere to local regulations for disposing of epoxy adhesive waste.

- Minimize waste: Mix only the amount of adhesive needed for the job to reduce waste.

Conclusion

Conclusion

Industrial strength epoxy adhesive is a powerful and versatile tool that has become indispensable across numerous industries. Its unmatched bonding strength, resistance to environmental stressors, and long-lasting durability make it an ideal choice for various applications. Professionals and DIY enthusiasts can achieve superior project results by understanding the properties and best practices for using this adhesive. With proper surface preparation, mixing, application, and curing, industrial strength epoxy adhesive can deliver exceptional performance, ensuring that bonds remain secure and durable for years.

For more about the power of industrial strength epoxy adhesive: applications, benefits, and best practices, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.