The Power and Versatility of One-Component Epoxy Adhesive: A Comprehensive Guide

The Power and Versatility of One-Component Epoxy Adhesive: A Comprehensive Guide

Epoxy adhesives are a cornerstone in various industries, providing a reliable and strong bond for materials ranging from metals and plastics to wood and ceramics. Among the many types of epoxy adhesives, one-component ones stand out due to their convenience, ease of use, and exceptional bonding capabilities. This article delves into the features, advantages, applications, and considerations for choosing one-component epoxy adhesive, exploring why it’s an essential tool in industrial and DIY settings.

What is a One-Component Epoxy Adhesive?

One-component epoxy adhesive is a type of adhesive that requires no mixing with hardeners or activators. Unlike traditional two-part epoxy adhesives, which must be mixed before use, one-component epoxies come pre-mixed in a single package. They are ready for application right out of the container. This makes them exceptionally user-friendly, reducing preparation time and minimizing the chances of mixing errors.

- Pre-mixed formulation:One-component epoxy adhesives come as a single, ready-to-use compound.

- Curing process:These adhesives cure when exposed to moisture or heat, eliminating the need for additional components.

- Consistency:They are typically thick and viscous, offering a durable and strong bond when applied to the surfaces.

How One-Component Epoxy Adhesive Works

The curing process of one-component epoxy adhesive occurs through a chemical reaction triggered by external factors like moisture, heat, or air. Unlike their two-part counterparts, which require mixing resin and hardener, one-component epoxies use a formulation that includes pre-reacted components. These adhesives often contain a curing agent that remains dormant until activated by specific environmental conditions.

- Moisture-cured systems:These adhesives use ambient humidity to initiate the curing process.

- Heat-cured systems:Some one-component epoxies require heat to activate the curing process.

- Storage and shelf life:Because they are pre-mixed and don’t require immediate activation, they have a longer shelf life and are easier to store.

Key Features and Advantages of One-Component Epoxy Adhesive

One-component epoxy adhesives offer numerous benefits that make them suitable for professional and consumer use. Here are some of the standout advantages:

Ease of Use

- No mixing required:Saves time and reduces the risk of improper mixing.

- Convenient for minor projects: Ideal for users who need a quick and straightforward solution without extensive preparation.

Long Shelf Life

- Ready-to-use formulation:Unlike two-part epoxies, which may have a limited shelf life after opening, one-component adhesives can last longer, making them more convenient for infrequent use.

Strong Bonding Properties

- Durability:One-component epoxy adhesives create highly durable and long-lasting bonds.

- Versatility:They can bond various materials, including metal, wood, glass, ceramics, and certain plastics.

Resistant to Harsh Conditions

- Chemical resistance:One-component epoxy adhesives resist many chemicals, including oils, solvents, and acids.

- Temperature resistance:They can withstand high and low temperatures, making them suitable for indoor and outdoor applications.

Prevents Waste

- No mixing mistakes:There is no need to mix in specific ratios, significantly reducing the potential for Waste.

Applications of One-Component Epoxy Adhesive

One-component epoxy adhesives are highly versatile and can be used across various industries and applications. Here are some common uses:

Automotive Industry

- Bonding parts: Used to bond vehicle parts such as mirrors, trim, and panels.

- Structural repairs:It helps repair components exposed to stress and harsh conditions.

Construction and Building

- Concrete bonding:One-component epoxies are excellent for bonding concrete to metal, wood, and other substrates.

- Sealing cracks:They can seal and repair cracks in walls, floors, and foundations.

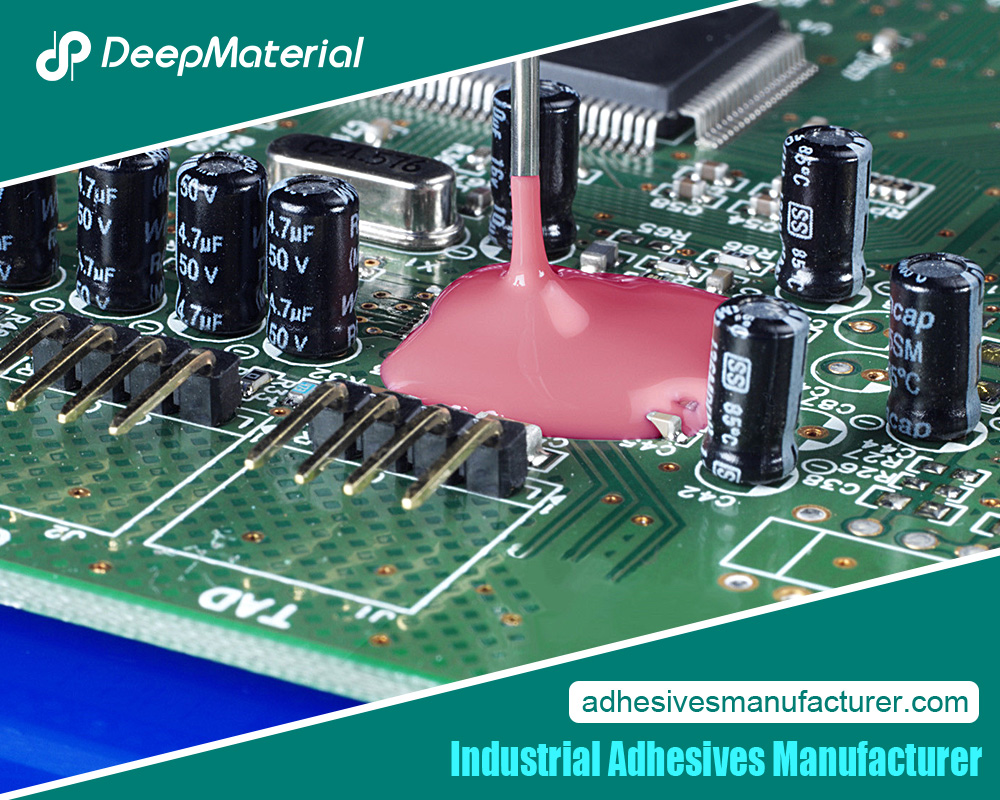

Electronics

- Component assembly:These adhesives are often used in the assembly of electronic components, offering intense, permanent bonds without the need for screws or other fasteners.

- Encapsulation and potting:One-component epoxies offer a moisture-resistant and insulating solution to protect sensitive electrical components.

Marine Industry

- Waterproof bonding:They create bonds between different materials, making them ideal for boat repair and marine construction.

- Repairing fiberglass:One-component epoxies are frequently used to repair cracks and chips in fiberglass.

DIY Projects and Home Improvement

- Quick fixes: Are ideal for small repair jobs around the house, such as fixing broken ceramic tiles, restoring furniture, or repairing plastic items.

- Crafting and model building:DIY enthusiasts and hobbyists use one-component epoxy adhesives for various projects, such as assembling models, sculptures, and artwork.

How to Use One-Component Epoxy Adhesive

Using a one-component epoxy adhesive is straightforward. However, following the correct procedure ensures the best results:

Step-by-Step Process:

Surface Preparation:

- Ensure the surfaces to be bonded are clean, dry, and free from oil, dust, or grease.

- Roughen smooth surfaces to improve adhesion.

Application:

- Apply the adhesive evenly to one of the surfaces. A small amount is usually sufficient, as the adhesive has strong bonding properties.

- Press the two surfaces together firmly.

Curing:

- Allow the adhesive to cure under the appropriate conditions (humidity or heat) according to the manufacturer’s instructions.

- Curing time varies, but the adhesive should form a strong bond after 24 hours.

Final Check:

- After the curing period, check the bond for strength and durability.

- Apply a second layer or reapply the adhesive for extra reinforcement if necessary.

Factors to Consider When Choosing One-Component Epoxy Adhesive

While one-component epoxy adhesives are incredibly versatile, there are a few key factors to consider when selecting the right one for your project:

Type of Materials

- Ensure the adhesive is suitable for the materials you intend to bond. Some one-component epoxies are formulated for metals, while others are better for plastics or wood.

Curing Conditions

- Consider whether the adhesive requires heat or moisture to cure, which will impact the application environment.

Viscosity and Flow

- The viscosity of the adhesive matters depending on the application. A low-viscosity adhesive might be preferred for precise applications, while thicker adhesives are better for gap-filling or larger surfaces.

Strength Requirements

- Evaluate the bond strength required. Opt for an epoxy with higher tensile strength for high-stress or load-bearing applications.

Environmental Resistance

- If your project will be exposed to extreme conditions (such as high temperatures or moisture), select an epoxy with enhanced resistance to these factors.

Safety Considerations and Handling Tips

Even though one-component epoxy adhesives are easier to use, safety should always be a priority:

- Wear protective gear:Gloves, goggles, and protective clothing should be worn when applying the adhesive.

- Ventilation:Ensure proper ventilation to avoid inhaling fumes.

- Storage: Store epoxy adhesives in a cool, dry place away from direct sunlight, keeping the container sealed when not in use.

Conclusion

One-component epoxy adhesives are a powerful and versatile tool for various applications. Whether you are working on a DIY project, repairing household items, or performing professional-level tasks in industries like construction, automotive, or electronics, these adhesives offer convenience, strength, and reliability. Their easy-to-use, pre-mixed formulation simplifies the bonding process, making them an invaluable asset for seasoned professionals and first-time users. By understanding their key features, benefits, and proper usage, you can ensure the best results every time, making one-component epoxy adhesives the go-to solution for all your bonding needs.

For more about a complete guide to the power and versatility of one-component epoxy adhesive: a comprehensive guide, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.