The Mystery and Application of Circuit Board Potting

The Mystery and Application of Circuit Board Potting

In today’s highly digitalized and intelligent era, electronic devices have become an indispensable part of our lives and work. From smart phones, computers to automotive electronics and industrial control systems, the core of every electronic device is inseparable from the circuit board. And circuit board potting, as an important circuit board protection technology, is playing an increasingly crucial role.

What is Circuit Board Potting

Circuit board potting, simply speaking, is to inject or cover a specific material on the circuit board to provide multiple functions such as physical protection, electrical insulation, moisture resistance, dust prevention, and corrosion resistance. The potting material usually has good fluidity and curing performance, and can form a uniform and solid protective layer on the surface of the circuit board.

The potting process can be completed by manual operation or automated equipment. In manual potting, the operator needs to use a syringe or other tools to carefully apply the potting material on the circuit board; while automated potting usually uses a potting machine, which can achieve more efficient and accurate potting operations.

Materials for Circuit Board Potting

Materials for Circuit Board Potting

- Epoxy Resin

Epoxy resin is a common circuit board potting material, with excellent electrical insulation performance, mechanical strength, and chemical stability. It can cure at room temperature or under heating conditions to form a hard and transparent protective layer. However, the flexibility of epoxy resin is relatively poor and may not be suitable in some environments that require greater vibration and shock resistance.

- Silicone Rubber

Silicone rubber has good flexibility, high temperature resistance, and weather resistance, and is a commonly used circuit board potting material in high-demanding environments. It can maintain good performance within a wide temperature range and has good resistance to vibration and shock. But the price of silicone rubber is relatively high, and the curing time is long.

- Polyurethane

Polyurethane potting material has good bonding performance, flexibility, and wear resistance. It can cure in a short time and can provide certain waterproof and dustproof effects. However, the electrical insulation performance of polyurethane is relatively weak and may not be suitable in some occasions with high electrical performance requirements.

- Acrylate

Acrylate potting material has the advantages of fast curing speed, high transparency, and strong bonding force. It is suitable for circuit board potting with high appearance requirements, but its performance in high temperature resistance and chemical corrosion resistance is relatively weak.

The Process Flow of Circuit Board Potting

- Preparation Work

Before conducting circuit board potting, the circuit board needs to be cleaned and pre-treated to remove impurities such as dust, oil stains, and oxides on the surface. At the same time, potting materials, potting equipment, and molds also need to be prepared.

- Mixing Potting Materials

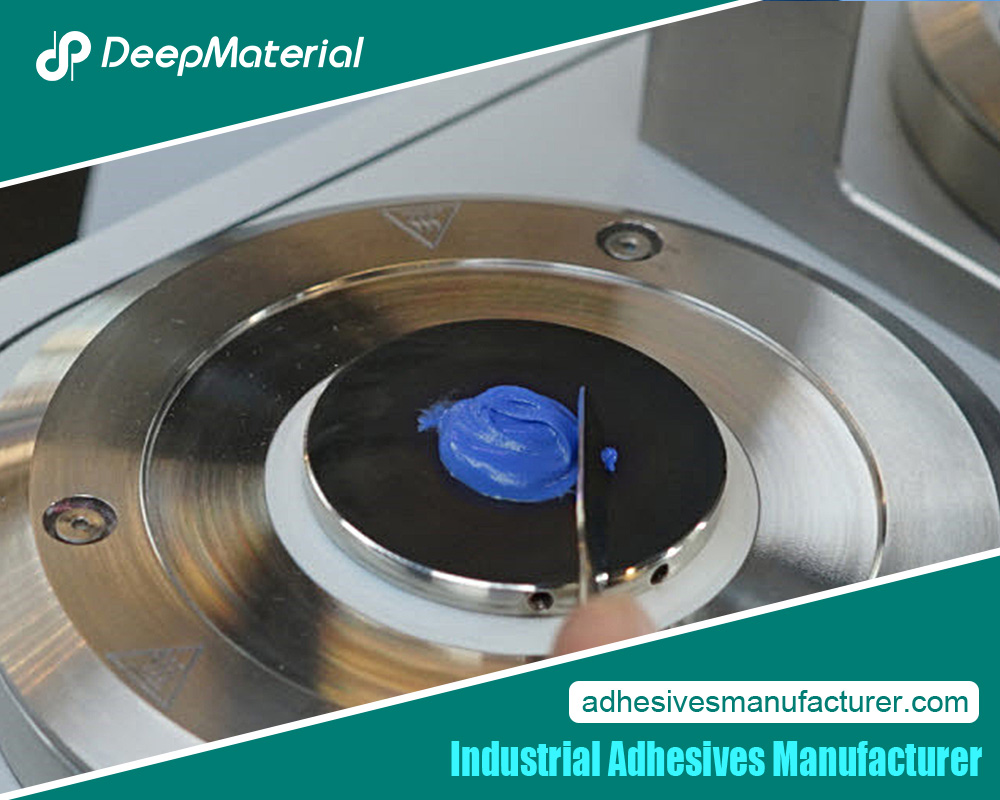

According to the requirements of the potting material, mix the main agent and curing agent in a certain proportion. During the mixing process, it is necessary to stir thoroughly to ensure the stable performance of the potting material.

- Potting Operation

Inject the mixed potting material into the mold or directly apply it to the circuit board. During the potting process, it is necessary to pay attention to controlling the flow and thickness of the potting material to ensure its uniform coverage of all parts of the circuit board.

- Curing

After the potting is completed, place the circuit board in the curing equipment for curing. The curing time and temperature depend on the type and requirements of the potting material. During the curing process, it is necessary to keep the environment clean and stable to avoid interference with the curing process.

- Post-treatment

After curing is completed, post-treatment is carried out on the potted circuit board, such as removing excess potting material and trimming the edges. At the same time, the quality of the circuit board needs to be inspected to ensure that it meets relevant standards and requirements.

Advantages of Circuit Board Potting

- Physical Protection

The potting material can provide a solid shell for the circuit board, effectively preventing the circuit board from mechanical damage such as collisions, scratches, and squeezes during transportation, installation, and use.

- Electrical Insulation

Good electrical insulation performance is one of the important advantages of circuit board potting. It can prevent short circuits and leakage phenomena between electronic components on the circuit board, improving the stability and reliability of the circuit.

- Moisture and Dust Resistance

The potting material can effectively prevent moisture and dust from entering the interior of the circuit board, avoiding circuit failures and corrosion caused by dampness and dust.

- Corrosion Resistance

In some harsh environments, such as those with high humidity, high salinity, and chemically corrosive gases, the potting material can provide effective corrosion protection for the circuit board, prolonging the service life of the circuit board.

- Heat Dissipation

Some potting materials have good thermal conductivity and can help the electronic components on the circuit board to dissipate heat, improving the working stability and reliability of the electronic device.

Application Fields of Circuit Board Potting

- Consumer Electronics

In consumer electronic products such as smart phones, tablets, and laptops, circuit board potting technology is widely used. It can protect the circuit board from the influence of collisions, drops, and dampness in daily use, improving the reliability and stability of the product.

- Automotive Electronics

Automotive electronic systems have extremely high requirements for reliability and stability. Circuit board potting can protect automotive electronic control units (ECUs), sensors, and other electronic components from the influence of vibration, high temperature, dampness, and chemical corrosion, ensuring the normal operation of the vehicle and safety.

- Industrial Control

In industrial control systems, circuit boards are often exposed to harsh environments such as high temperature, high humidity, dust, and corrosive gases. Potting technology can provide reliable protection for circuit boards and ensure the stable operation of industrial equipment.

- Medical Electronics

Medical electronic devices have extremely strict requirements for safety and reliability. Circuit board potting can prevent the invasion of bacteria and viruses and protect electronic components from the influence of dampness and chemicals, ensuring the normal operation of medical equipment and the safety of patients.

- Aerospace

In the aerospace field, electronic devices need to withstand extreme conditions such as temperature, pressure, and vibration. Circuit board potting technology can provide reliable protection for aerospace electronic equipment and ensure its normal operation in harsh environments.

Development Trends of Circuit Board Potting

- Research and Development of High-performance Materials

With the continuous improvement of the performance of electronic devices and the increasingly harsh application environments, the performance requirements for potting materials are also getting higher and higher. In the future, potting materials with higher electrical insulation performance, better thermal conductivity, stronger weather resistance, and chemical corrosion resistance will be developed.

- Automated Production

In order to improve production efficiency and consistency in product quality, automated production of circuit board potting will become the development trend in the future. Automated potting equipment will be able to achieve more accurate potting operations, higher production efficiency, and lower production costs.

- Green and Environmental Protection

With the continuous enhancement of environmental awareness, green and environmentally friendly potting materials and production processes will become the development direction in the future. The research and development and use of low volatile organic compound (VOC), halogen-free, and recyclable potting materials will help reduce environmental pollution.

- Multi-functional Integration

The future circuit board potting technology will not only be limited to providing functions such as physical protection and electrical insulation but also integrate multiple functions such as heat dissipation, electromagnetic shielding, and fire prevention to meet the increasingly complex needs of electronic devices.

Challenges and Solutions of Circuit Board Potting

- Bubble Problem

During the potting process, due to the fluidity of the potting material and the chemical reaction during the curing process, bubbles may be generated in the potting layer. The presence of bubbles will reduce the performance of the potting material, such as electrical insulation performance and mechanical strength. Solutions include optimizing the potting process parameters, using vacuum defoaming equipment, and adding defoamers.

- Stress Problem

The potting material will generate shrinkage stress during the curing process, which may cause the circuit board to deform or damage electronic components. To reduce the impact of stress, methods such as selecting potting materials with low shrinkage rate, optimizing the potting thickness, and using stepwise curing can be adopted.

- Heat Dissipation Problem

For some electronic devices with high power, the heat dissipation performance of the potting material may not meet the requirements. Solutions include selecting potting materials with good thermal conductivity, adding thermal conductive fillers in the potting layer, or adopting heat dissipation structure design.

- Maintenance Difficulty

Once the circuit board is potted, maintenance and replacement of electronic components will become difficult. To solve this problem, local potting or detachable potting structures can be adopted to facilitate the operation when maintenance is required.

Conclusion

Conclusion

Circuit board potting, as an important circuit board protection technology, plays a vital role in the reliability and stability of electronic devices. With the continuous development of electronic technology and the continuous expansion of application fields, circuit board potting technology is also constantly innovating and progressing. In the future, we will see more high-performance, environmentally friendly, multi-functional, and automated circuit board potting technologies, providing stronger support for the development of electronic devices.

For more about a complete guide to the mystery and application of circuit board potting, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.