The Essential Guide to Choosing Industrial Electronic Component Adhesive Suppliers

The Essential Guide to Choosing Industrial Electronic Component Adhesive Suppliers

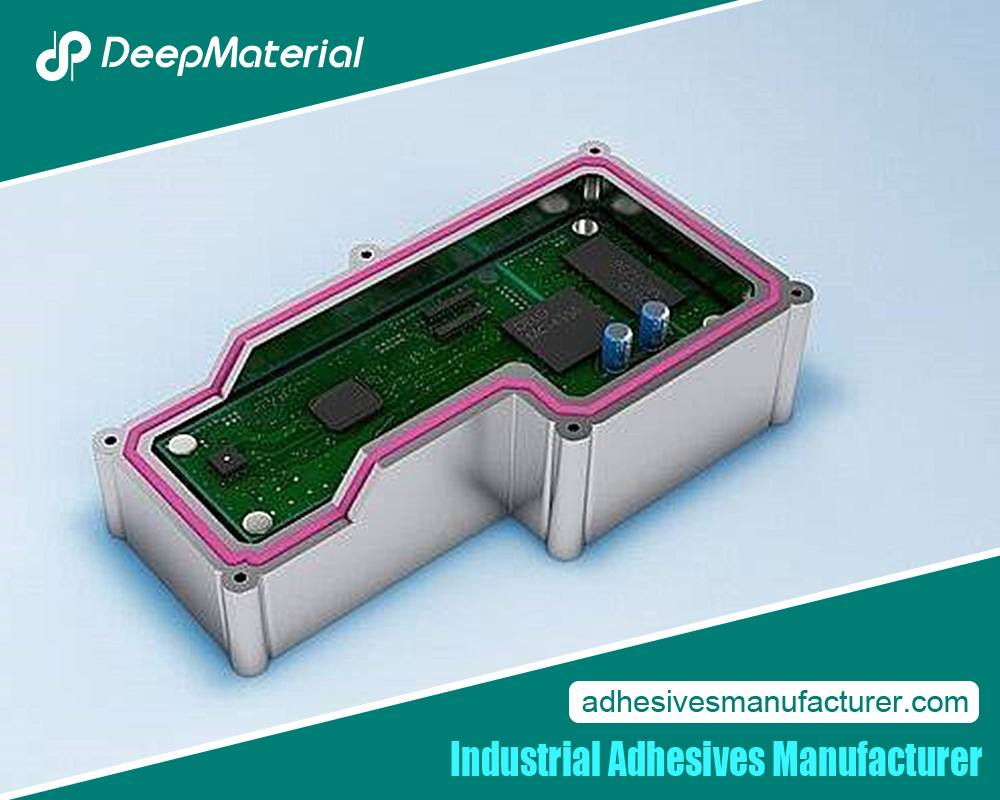

The adhesive used to secure components in electronic devices is crucial for durability, performance, and reliability. Choosing a suitable industrial electronic component adhesive supplier can significantly impact product quality and assembly efficiency. This guide explores vital considerations and factors when selecting suppliers in this specialized industry.

Understanding the Importance of Industrial Electronic Component Adhesives

Critical Role in Electronics Manufacturing

Industrial electronic component adhesive suppliers are critical in the seamless functioning of electronics manufacturing processes. These suppliers provide specialized adhesives that ensure the secure attachment of various elements, thereby enhancing the reliability and longevity of electronic devices.

- Secure Component Attachment:Adhesives ensure components remain firmly in place, resisting vibrations and mechanical stresses during operation.

- Enhanced Reliability:Adhesives minimize the risk of connection failures and damage by preventing component movement, thereby increasing the overall reliability of electronic devices.

- Effective Thermal Management:Facilitates heat dissipation from components, improving overall system efficiency and preventing thermal degradation.

- Electrical Insulation:Adhesives offer high dielectric strength, which is crucial for isolating electrical connections and reducing the risk of short circuits.

- Customized Solutions: Suppliers offer tailored adhesive formulations to meet specific application requirements, ensuring compatibility with diverse materials and manufacturing processes.

- Quality Assurance:Reliable suppliers adhere to stringent standards, providing adhesives that meet industry certifications and regulatory requirements.

- Technical Support: They offer expertise in adhesive selection and application techniques, assisting manufacturers in optimizing assembly processes and achieving consistent results.

- Innovation and Development: Continuous research and development efforts lead to the introduction of advanced adhesive technologies that address emerging challenges in electronics manufacturing.

Impact on Product Quality

Choosing suitable industrial electronic component adhesive suppliers ensures optimal product quality and performance. The adhesive used significantly impacts the longevity and reliability of electronic devices, directly influencing their durability under various environmental conditions, such as moisture and temperature fluctuations. Suppliers who specialize in high-quality adhesives tailored for electronic components offer several benefits:

- Enhanced Longevity: Quality adhesives from reliable suppliers extend the lifespan of electronic devices by providing robust bonding that withstands wear and tear over time.

- Improved Reliability: The adhesive’s strength and resistance to environmental factors ensure consistent performance, reducing the likelihood of premature failure or malfunction.

- Protection Against Environmental Factors:Adhesives from reputable suppliers offer superior resistance to moisture ingress and temperature variations, safeguarding internal electronic components from damage.

- Consistent Quality Assurance: Established suppliers adhere to stringent quality control measures, ensuring each batch of adhesive meets industry standards for reliability and performance.

- Compatibility and Adaptability: Suppliers who understand the specific requirements of electronic applications can offer adhesives tailored to diverse substrates and assembly processes, enhancing overall product compatibility and adaptability.

Regulatory and Compliance Requirements

Ensuring adherence to regulatory and compliance requirements is paramount for product integrity and market acceptance when evaluating industrial electronic component adhesive suppliers. Key considerations include:

- RoHS Compliance: Verification that adhesives do not contain restricted substances like lead and mercury.

- ISO Standards: Certification indicating adherence to international quality management systems.

- UL Certification:Ensures the safety and reliability of adhesives for electronic components.

- Documentation:Clear evidence of compliance with regulatory standards to streamline approval processes.

Key Considerations When Choosing Suppliers

Key Considerations When Choosing Suppliers

Product Range and Specialization

Industrial electronic component adhesive suppliers offer a diverse product range tailored to specific application needs, enhancing performance and reliability in electronic manufacturing. Key offerings include:

- Variety of Adhesives: Options like epoxy, silicone, and acrylic cater to different bonding requirements and substrate materials.

- Specialized Formulations:Adhesives designed for specific functions like heat dissipation or electrical insulation meet unique application demands.

- Custom Solutions:Suppliers capable of developing tailored formulations address complex challenges in electronic assembly.

Quality and Consistency

Industrial electronic component adhesive suppliers prioritize quality and consistency to ensure reliable performance in varied environmental conditions. Key considerations include:

- Performance Under Varied Conditions: Adhesives tested for resilience against temperature fluctuations and humidity levels maintain stability over time.

- Batch-to-Batch Consistency: Rigorous quality control measures ensure uniformity in adhesive properties across production runs.

- Reliability Assurance: Suppliers with robust quality assurance processes deliver adhesives that consistently meet performance expectations.

Technical Support and Expertise

Technical support and expertise are paramount when seeking industrial electronic component adhesive suppliers. These suppliers offer comprehensive assistance, including the availability of technical documentation and specifications essential for making informed decisions. They excel in guiding customers through selecting suitable adhesives for specific electronic components, ensuring optimal performance and reliability. This level of support underscores their commitment to delivering high-quality products tailored to the unique needs of electronic manufacturing industries.

- Technical support and expertise from experienced suppliers

- Availability of detailed technical documentation and specifications

- Guidance in selecting the appropriate adhesive for specific electronic components

Supply Chain Reliability

Our chosen industrial electronic component adhesive suppliers ensure exceptional supply chain reliability and operational efficiency. They excel in:

- On-time delivery and precise inventory management, ensuring no disruptions in production schedules.

- Robust capacity to seamlessly manage fluctuating demand, maintaining consistent product availability.

- Commitment to quality assurance and customer satisfaction, offering reliable solutions for industrial adhesive needs.

Criteria for Evaluating Potential Suppliers

Industry Reputation and Experience

Our industrial electronic component adhesive suppliers are recognized for their stellar industry reputation and extensive experience in the electronics manufacturing sector. Key highlights include:

- Positive reviews and glowing testimonials from current clients underscore their reliability and performance.

- It has a proven track record of delivering high-quality adhesive solutions that meet stringent industry standards.

- Expertise in understanding the unique requirements of electronic component manufacturing, ensuring tailored and effective adhesive solutions that enhance product performance and reliability. Their established credibility makes them a trusted partner in the industry.

Quality Assurance Processes

Our industrial electronic component adhesive suppliers uphold rigorous quality assurance processes, ensuring excellence and reliability in every product. Key aspects include:

- Implementation of comprehensive testing methodologies and stringent quality control measures throughout manufacturing.

- Adherence to international standards and regulations, guaranteeing compliance with industry requirements.

- Continuous improvement initiatives to enhance product performance and durability, meeting the dynamic needs of electronic component applications. Their commitment to quality assurance underscores their reputation as trusted providers of high-performance adhesives in the industrial sector.

Innovation and Research

Our industrial electronic component adhesive suppliers are at the forefront of innovation and research, driving advancements in adhesive technology. Key highlights include:

- Significant investment in R&D to develop new adhesive formulations that enhance performance and efficiency in electronic component applications.

- Proactive adaptation to emerging trends and technologies, ensuring their products meet the evolving needs of the industry.

- Collaboration with industry experts and stakeholders to anticipate future demands and innovate accordingly. Their commitment to innovation underscores their leadership in providing cutting-edge adhesive solutions for industrial electronics.

Customer Support and Communication

Our customer support team excels in responsiveness to inquiries and technical assistance, ensuring a seamless experience for all our clients. We pride ourselves on promptly addressing concerns or issues and prioritizing customer satisfaction. Whether troubleshooting technical issues or providing guidance, our dedicated team is committed to delivering prompt and practical solutions. Our approach is built on clear and empathetic communication, ensuring every customer feels valued and supported throughout their interaction with us.

Conclusion

Conclusion

Choosing a suitable industrial electronic component adhesive supplier involves careful evaluation of technical expertise, product quality, and supply chain capabilities. Manufacturers can ensure that their electronic devices meet stringent performance and durability requirements by prioritizing reliability, innovation, and customer support. Investing in a trusted supplier enhances product quality and contributes to long-term success in the competitive electronics market.

For more about the essential guide to choosing industrial electronic component adhesive suppliers, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.