The Comprehensive Guide to Industrial Electric Motor Adhesive Suppliers

The Comprehensive Guide to Industrial Electric Motor Adhesive Suppliers

In the competitive landscape of industrial manufacturing, electric motors are fundamental components driving various applications, from automotive to aerospace. The reliability and performance of these motors heavily depend on the adhesives used to assemble and secure their components. As manufacturers seek to enhance operational efficiency, understanding the role of industrial electric motor adhesives becomes crucial. This blog post delves deep into industrial electric motor adhesive suppliers, exploring the types of adhesives available, key considerations when selecting suppliers, and a detailed overview of prominent players in the market.

Understanding Industrial Electric Motor Adhesives

Industrial electric motor adhesives are specially formulated bonding agents to assemble and secure various components within electric motors. These adhesives must withstand rigorous conditions such as high temperatures, mechanical stress, and exposure to chemicals, making them essential for:

- Structural Integrity: Ensuring that motor parts remain securely bonded during operation.

- Sealing Applications:Protecting internal components from moisture, dust, and contaminants.

- Electrical Insulation:Preventing short circuits and electrical failures by insulating sensitive parts.

Importance of Adhesives in Electric Motors

Adhesives play a pivotal role in the performance and longevity of electric motors. Some key benefits include:

- Enhanced Performance: Quality adhesives improve the operational efficiency of electric motors.

- Reduced Weight: Adhesives can replace traditional fastening methods, reducing overall weight.

- Cost-Effectiveness:They can lower assembly costs by simplifying processes and reducing the number of parts needed.

Types of Adhesives Used in Electric Motors

The choice of adhesive plays a vital role in ensuring the components’ efficiency, reliability, and longevity in the design and manufacturing of electric motors. Different types of adhesives are employed depending on the materials being bonded, the operating conditions, and the motor’s specific requirements. Below are some of the most commonly used adhesives for electric motors and their key characteristics.

Epoxy Adhesives

Epoxy adhesives are renowned for their strong bonding capabilities and versatility in various applications.

- High Strength: Epoxy adhesives provide exceptional tensile and shear strength, making them suitable for bonding metal parts, including rotor and stator components.

- Temperature Resistance: They can withstand high temperatures, often exceeding 150°C, which is crucial for the heat generated in motor operation.

- Chemical Resistance: Electric motors’ resistance to various chemicals, oils, and solvents contributes to their durability, especially in harsh environments.

Polyurethane Adhesives

Polyurethane adhesives are increasingly popular due to their flexibility and adhesion properties.

- Flexibility: These adhesives offer good elasticity, allowing them to absorb vibrations and thermal expansions without cracking or losing adhesion.

- Moisture Resistance:They excel in humid conditions, preventing moisture ingress that can lead to corrosion and degradation of motor components.

- Broad Substrate Compatibility:Polyurethane adhesives bond well to various materials, including plastics, metals, and composites, making them versatile for different motor designs.

Silicone Adhesives

Silicone adhesives are particularly valued for their unique properties in extreme environments.

- Temperature Range:They maintain performance across a wide temperature range, often from -50°C to 250°C, making them ideal for motors that experience fluctuating temperatures.

- Electrical Insulation: Silicone adhesives possess excellent dielectric properties, providing electrical insulation and protecting sensitive components.

- Weather Resistance:Their ability to resist UV light, moisture, and extreme temperatures makes them suitable for indoor and outdoor motor applications.

Acrylic Adhesives

Acrylic adhesives are known for their quick curing times and intense bonds.

- Rapid Curing: These adhesives cure quickly, significantly reducing assembly time and increasing production efficiency.

- Impact Resistance: Acrylics strongly resist impact and stress, ensuring motor components remain securely bonded under operational conditions.

- Clarity and Aesthetics: They are often clear or tinted, making them suitable for applications where component visibility is essential.

Anaerobic Adhesives

Anaerobic adhesives are specialized for applications involving metal-to-metal bonding.

- Locking Mechanism:They are commonly used to lock threaded fasteners, preventing loosening due to vibration or thermal cycling.

- Sealing Capabilities: Anaerobic adhesives also act as effective sealants, preventing leaks in critical motor areas, such as coolant passages or oil seals.

- Low Viscosity: Their ability to flow into tight spaces ensures strong adhesion even in challenging geometries.

Hot Melt Adhesives

Hot melt adhesives are utilized in specific motor assembly applications due to their ease of use.

- Fast Application: They can be applied quickly using a hot glue gun, making them ideal for assembly line environments.

- Immediate Bonding: These adhesives provide a strong initial bond, allowing for fast assembly and handling.

- Versatile Applications:Hot melt adhesives are suitable for bonding various materials, including plastics and textiles. They are often used to insulate and secure components.

Key Considerations When Choosing Adhesive Suppliers

Selecting the right adhesive supplier is critical for manufacturers. Here are vital factors to consider:

Product Range

A comprehensive product range ensures manufacturers can find the suitable adhesive for specific applications. Look for:

- Multiple adhesive formulations (epoxy, polyurethane, silicone, etc.)

- Specialty adhesives designed for electric motor applications

- Options for high-temperature and chemical resistance

Quality Assurance

The quality of adhesives directly impacts motor performance. Choose suppliers that maintain high-quality standards:

- ISO certification and compliance with industry regulations (e.g., RoHS, REACH)

- Availability of product test results and technical data sheets

- Regular quality audits and control processes

Technical Support

Robust technical support is essential for successful adhesive application:

- Guidance on adhesive selection based on specific needs

- Assistance with application techniques and best practices

- Custom formulation services to meet unique requirements

Delivery and Service

Efficient logistics and customer service can significantly influence production timelines:

- Reasonable lead times and reliable shipping options

- Responsive customer service for inquiries and issues

- Flexibility in order fulfillment and inventory management

Emerging Trends in Adhesive Technology

Sustainability

As industries move towards more sustainable practices, adhesive suppliers develop eco-friendly formulations. Key trends include:

- Biobased adhesives that reduce reliance on petroleum-based products.

- Lower volatile organic compounds (VOCs) to minimize environmental impact.

- Increased focus on recyclability and waste reduction in adhesive applications.

Smart Adhesives

Developing intelligent adhesives that can adapt to their environment is gaining traction. These adhesives can:

- Change properties in response to temperature or pressure.

- Provide real-time monitoring of structural integrity.

- Enhance the performance of electric motors in dynamic environments.

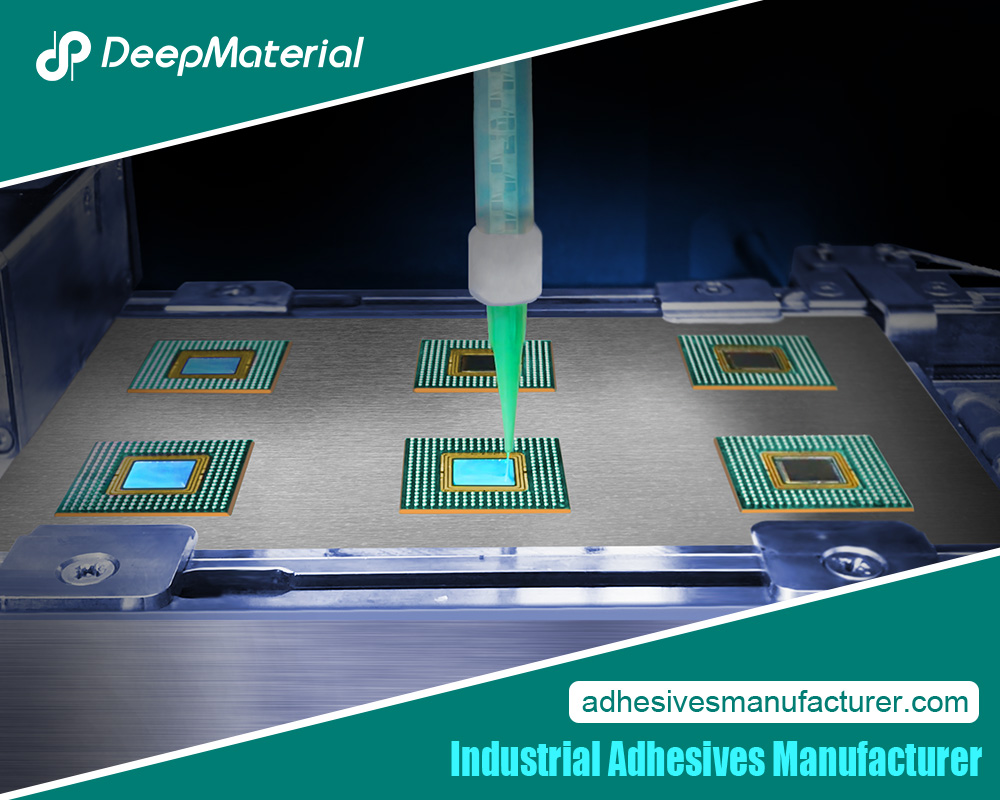

Automation and Robotics

The integration of automation in adhesive application processes is transforming manufacturing. Benefits include:

- Increased precision and consistency in adhesive application.

- Reduced labor costs and increased efficiency.

- Enhanced safety by minimizing human exposure to adhesives.

Case Studies: Successful Applications of Adhesives in Electric Motors

Case Study 1: Aerospace Industry

- Background: A leading aerospace manufacturer needed a reliable adhesive for assembling high-performance electric motors in aircraft.

- Solution:The manufacturer chose a 3 M high-temperature epoxy adhesive, which ensures durability and resistance to extreme conditions.

- Outcome: The adhesive provided a robust bond, enhancing the motors’ overall performance and meeting strict aerospace standards.

Case Study 2: Automotive Industry

- Background: An automotive supplier required a flexible adhesive solution for electric motor components exposed to vibration and movement.

- Solution: B. Fuller supplied a polyurethane adhesive that required flexibility and moisture resistance.

- Outcome:The adhesive solution significantly improved the longevity of the motors, reducing warranty claims and increasing customer satisfaction.

Case Study 3: Renewable Energy Sector

- Background: A renewable energy company needed an adhesive for assembling wind turbine electric motors.

- Solution: Dow provided a specialized silicone adhesive for outdoor exposure and temperature fluctuations.

- Outcome: The adhesive improved the durability of the motors and contributed to the overall efficiency of the wind turbines.

Conclusion

Choosing the right industrial electric motor adhesive supplier is crucial to ensuring electric motors’ performance, reliability, and longevity. Manufacturers can make informed decisions by understanding the types of adhesives available and considering factors such as product range, quality assurance, technical support, and delivery service. Leading suppliers like 3M, Henkel, H.B. Fuller, Dow, LORD Corporation, and Sika offer innovative solutions tailored to the industry’s unique demands. As trends toward sustainability and automation continue to shape the adhesive landscape, manufacturers that partner with suitable suppliers will be well-positioned to thrive in the ever-evolving market. Investing in quality adhesives enhances motor performance, drives operational efficiency, and contributes to the overall success of manufacturing operations.

For more about a complete guide to the comprehensive guide to industrial electric motor adhesive suppliers, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.