The best potting compound for electronics

The best potting compound for electronics

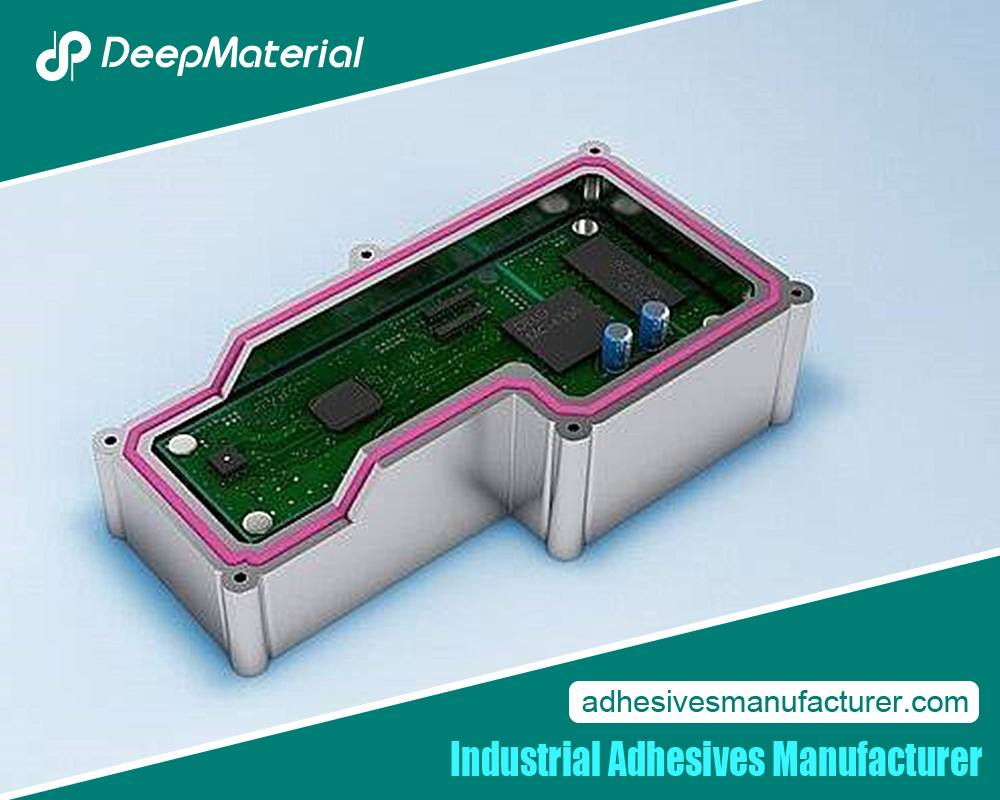

We live in an era where reliance on electronics has grown to an undeniable extent. Electronic components require necessary protection from harsh environmental effects, mechanical stress, and electrical interference for efficient and optimal operation. Potting is of paramount importance in electronic functionality. To apply the perfect potting layer, it is essential to find the perfect potting compound. Choosing the right potting compound for electronics is like choosing the perfect shield to protect your components efficiently. The right potting compound offers the needed protection without compromising the performance and operations of electronics.

There are plenty of potting compounds available in the market. Finding the perfect one can be quite confusing among all the available options. For your ease, we are sharing the characteristics of the best potting compounds that can guide you in finding the best potting compound for electronics. The characteristics are described in terms of expectations that you should have from the potting compound such as performance considerations, compatibility, environmental impact, and, application requirements.

Performance consideration: High-performing potting compounds are more desirable to protect the electronic components. To ensure that the potting compound is high-performing, look out for these characteristics.

- Electric insulation: Potting compounds are desired to offer electrical insulation to lower the risk of electrical leakage and short circuits. This is why you need to make sure that the component you choose has a low dissipation factor and high dielectric strength or else it won’t give the desired performance.

- Environmental stability: Environmental factors can hurt the performance of potting compounds such as humidity, moisture, thermal fluctuations, and UV radiations. This is why you should look for a potting compound that can showcase exceptional environmental stability and can bear harsh environmental conditions in the long run without degrading.

- Resistance to chemicals: Electronics are normally exposed to multiple chemicals such as acids, cleaning agents, solvents, and oils. You need to find a potting compound that can resist chemicals. It should be able to withstand chemical exposure while maintaining the desired performance.

- Thermal conductivity: To maintain the longevity and reliability of your electronic devices, they must dissipate heat efficiently. This is why while choosing the potting compound make sure that it has good thermal conductivity. It should be able to transfer heat from the critical components of electronics effectively and dissipate in the surroundings.

- Mechanical properties: Mechanical stress is quite common in industrial setups. The potting compound you choose should have the flexibility and mechanical strength to bear the mechanical stress such as thermal cycling, shock, and vibrations. Potting compounds must not crack or degrade when exposed to mechanical stress.

Compatibility: The potting compound must be compatible with the material of the electronics to make sure that it creates a strong bond and adhesion with the material. Proper adhesion is of critical importance because if the potting compound does not form a strong bond then it won’t be able to properly protect the components of electronics. To choose the right potting compound you need to consider the substrate material (whether to choose between silicone, epoxy, or polyurethane), potting process (vacuum potting, manual dispensing, or injection molding), and cure method (heat cure, moisture cure, etc). Let us check out these considerations briefly to give you a little more idea.

- Substrate: Various potting compounds are formulated specificaaly for specific substrates. For instance, some of these are more compatible with plastics, some others are more attracted to metals or ceramics. While choosing a potting compound, you must make sure that it is compatible with the substrate of your electronic device to ensure efficient adhesion while ensuring superior performance.

- Application method: Make sure that you opt for the recommended method of application as per your electronic devices such as automated dispensing, manual dispensing, injection molding, or vacuum potting. Choose the method that seems more compatible with your substrate and device and is meant to offer you consistent and uniform adhesion.

- Curing method: Different potting compounds are formulated differently and require different curing methods such as room temperature curing, heat curing, moisture curing, and UV curing. You need to choose the most suitable curing method based on processing requirements and equipment.

Environmental impact: people are more conscious of the impact of industrial processes on the environment and prefer to adopt green and sustainable practices. While choosing the potting compound make sure that you consider the sustainable solution and compounds that are specifically formulated by keeping in mind the environmental impacts. For instance, the potting compound must be formulated with non-toxic additives, low volatile organic compounds, and recyclable packaging. Let us check out these three major considerations briefly.

- VOC: Volatile organic compounds (VOC) pollute the air and impose serious health risks for the environment and humans breathing that air. Choose the potting compounds that are formulated with low VOC content to ensure that you play your part in promoting a healthy work environment.

- Toxic substances: Never invest in a potting compound that is formulated with toxic substances such as mercury, lead, brominated flame retardants, and cadmium. these substances can be risky to human health as well as the environment. Choose those potting compounds that comply with standards of REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances).

- Recycled packaging: Make sure that you can recycle the potting compounds after they are used. Choose potting compounds that can be easily recycled and do not impose any hazardous impact on the environment while disposing.

Application requirements: Choose the potting compound while considering the specific application requirements which include temperature range, regulatory compliance, and functional environment.

Application requirements: Choose the potting compound while considering the specific application requirements which include temperature range, regulatory compliance, and functional environment.

- Temperature range: Choose the potting compound that coincides with the temperature range of the electronic assembly. This way you can ensure that the potting compound won’t degrade with fluctuation of temperature.

- Regulatory compliance: choose the potting compound that complies with regulatory standards such as MIL-STD (Military Standard), UL (Underwriters Laboratories), and IPC (Association Connecting Electronics Industries).

- Functional environment: Choose a potting compound that can withstand the environmental effects in which the electronic assembly is placed such as exposure to UV radiation, humidity, moisture, and mechanical stress.

For more about a complete guide to the best potting compound for electronics, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.