The Adhesive Manufacturing Industry in Japan: A Comprehensive Overview

The Adhesive Manufacturing Industry in Japan: A Comprehensive Overview

Japan is known for its technological innovation, precision engineering, and commitment to quality across various industries. The adhesive manufacturing sector is critical to Japan’s industrial landscape. Adhesive manufacturing companies in Japan have consistently driven innovation and quality in producing adhesives that meet the demands of diverse sectors such as automotive, electronics, construction, and consumer goods. This article provides a comprehensive overview of the adhesive manufacturing industry in Japan, exploring its history, key players, technological advancements, and prospects.

A Brief History of Adhesive Manufacturing in Japan

Early Development

- Pre-World War II Era: The adhesive industry in Japan began developing in the early 20th century, primarily driven by the need for adhesives in traditional crafts and industrial applications. Natural adhesives, such as starch-based and animal glue, were commonly used.

- Post-World War II Growth:After World War II, Japan experienced rapid industrialization, which led to increased demand for advanced adhesive solutions. This period saw the introduction of synthetic adhesives, including epoxy and polyurethane adhesives, which offered superior performance characteristics.

Technological Advancements

- 1970s-1980s: The 1970s and 1980s marked a period of significant technological advancement in the Japanese adhesive industry. Companies began investing heavily in research and development to create high-performance adhesives suitable for demanding electronics, automotive, and aerospace applications.

- 1990s-Present:In recent decades, Japan’s adhesive manufacturing companies have focused on developing environmentally friendly adhesives, responding to growing global awareness of environmental sustainability. The industry has seen innovations such as water-based adhesives and solvent-free formulations.

Key Players in Japan’s Adhesive Manufacturing Industry

Several companies dominate the adhesive manufacturing landscape in Japan, each contributing unique innovations and solutions.

1. Henkel Japan Ltd.

- Overview: A subsidiary of the German multinational corporation Henkel AG & Co. KGaA, Henkel Japan specializes in adhesive technologies for various industries, including automotive, electronics, and consumer goods.

- Innovations:Henkel Japan is known for its advanced adhesive products that offer high bond strength, durability, and resistance to extreme conditions. The company’s focus on sustainability has led to developing eco-friendly adhesives that reduce environmental impact.

2. Sekisui Chemical Co., Ltd.

- Overview:Sekisui Chemical is a leading manufacturer of Japanese high-performance adhesives and sealants. The company serves diverse industries, including automotive, construction, and electronics.

- Innovations: Sekisui Chemical is renowned for its acrylic and polyurethane-based adhesives that provide excellent adhesion, flexibility, and weather resistance. The company emphasizes research and development to create products that meet evolving industry needs.

3. ThreeBond Holdings Co., Ltd.

- Overview: ThreeBond is a global leader in producing industrial adhesives and sealants, with a strong presence in the automotive, aerospace, and electronics sectors.

- Innovations: ThreeBond’s adhesive solutions are known for their high-performance characteristics, including heat resistance, chemical resistance, and reliability under demanding conditions. The company’s products are widely used in automotive assembly and electronic device manufacturing.

4. Konishi Co., Ltd.

- Overview: Konishi is a prominent Japanese adhesive manufacturer that caters to the construction, automotive, and consumer goods industries.

- Innovations: Konishi’s adhesive offerings include a wide range of products, from construction adhesives with high bonding strength to consumer-friendly adhesives for household use. The company prioritizes product safety and environmental sustainability in its development process.

5. Cemedine Co., Ltd.

- Overview: Cemedine is a leading Japanese company specializing in adhesives, sealants, and industrial coatings. The company has a strong presence in the automotive and construction sectors.

- Innovations: Cemedine’s products are characterized by their versatility. They offer solutions for various applications, from automotive assembly to building construction. The company’s focus on research and development ensures that its products meet the highest quality standards.

Applications of Adhesives in Japanese Industries

Applications of Adhesives in Japanese Industries

The adhesive manufacturing industry in Japan serves a wide range of sectors, each with specific requirements and challenges.

Automotive Industry

The automotive industry is one of Japan’s largest consumers of adhesives, with applications ranging from vehicle assembly to component bonding.

- Structural Bonding: Adhesives bond various components, such as body panels, doors, and roofs, providing structural integrity and reducing vehicle weight.

- Interior Applications: Adhesives are crucial in assembling interior components, such as dashboards, seats, and trim, ensuring durability and aesthetic appeal.

- Electronic Systems: As electronic systems are increasingly integrated into vehicles, adhesives are used to bond and protect electronic components, ensuring their reliability and performance.

Electronics Industry

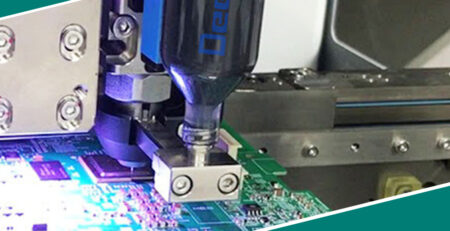

Japan’s electronics industry is globally recognized for its innovation and precision. It relies heavily on adhesives for device assembly and component bonding.

- Microelectronics: Adhesives assemble microelectronic devices, providing electrical insulation, thermal management, and mechanical stability.

- Display Technology: Adhesives are crucial in assembling display panels, such as LCDs and OLEDs, ensuring optical clarity and bonding strength.

- Consumer Electronics: Adhesives are used in the manufacture of consumer electronics, such as smartphones, tablets, and laptops, providing structural support and protection against environmental factors.

Construction Industry

The construction industry in Japan benefits from adhesive solutions that enhance building performance and sustainability.

- Structural Adhesives: Adhesives bond structural elements in construction, providing strength and stability to buildings and infrastructure.

- Sealants: Sealants are essential for waterproofing and weatherproofing applications, protecting structures from moisture and environmental damage.

- Insulation Applications: Adhesives bond insulation materials, improving energy efficiency and thermal performance in buildings.

Healthcare and Medical Devices

The healthcare industry relies on adhesives for medical devices and applications requiring biocompatibility and reliability.

- Medical Device Assembly:Adhesives assemble medical devices, ensuring precision, durability, and sterility.

- Wound Care and Dressings:Adhesives are used in wound care products, such as bandages and dressings, providing secure attachment and patient comfort.

- Biocompatible Adhesives:Japanese manufacturers develop biocompatible adhesives that meet stringent healthcare industry standards, ensuring safety and performance in medical applications.

Packaging Industry

The packaging industry in Japan utilizes adhesives for secure and efficient packaging solutions.

- Flexible Packaging: Adhesives are used in flexible packaging materials, providing strength, barrier properties, and seal integrity.

- Labeling and Branding: Adhesives are crucial for attaching labels and branding materials to packaging, ensuring visibility and durability.

- Sustainability Initiatives: Japanese companies are developing adhesives for sustainable packaging solutions, promoting recyclability and reducing environmental impact.

The Role of Research and Development in the Adhesive Industry

Research and development (R&D) drives innovation and competitiveness in Japan’s adhesive manufacturing industry.

Investment in Innovation

- R&D Facilities: Japanese adhesive manufacturers invest heavily in state-of-the-art research facilities, employing experts in chemistry, materials science, and engineering to develop cutting-edge adhesive solutions.

- Collaboration with Academia: Companies often collaborate with universities and research institutions to leverage academic expertise and advance adhesive technology.

Focus Areas in R&D

- Advanced Materials:R&D efforts focus on developing advanced materials that offer superior performance characteristics, such as high bond strength, flexibility, and resistance to environmental factors.

- Sustainability Initiatives: Sustainability is a key focus area, with R&D efforts aimed at developing eco-friendly adhesives, reducing volatile organic compounds (VOCs), and improving the recyclability of adhesive products.

- Smart Adhesive Technologies: Japanese companies are exploring the integration of smart technologies into adhesives, which would enable real-time monitoring of adhesive performance and structural health.

Challenges Facing the Japanese Adhesive Manufacturing Industry

Despite its strengths, the adhesive manufacturing industry in Japan faces several challenges that must be addressed to ensure continued growth and competitiveness.

Environmental Regulations

- Stringent Standards: Japan has stringent environmental regulations governing the production and use of adhesives, particularly concerning VOC emissions and hazardous materials. Compliance with these regulations requires significant investment in research and development.

- Sustainability Pressure: As global demand for sustainable products increases, adhesive manufacturers are under pressure to develop eco-friendly formulations and reduce their products’ environmental impact.

Global Competition

- International Market Dynamics: The adhesive industry is highly competitive globally, with companies from Europe, the United States, and other Asian countries vying for market share. Japanese manufacturers must innovate and differentiate their products to maintain a competitive edge.

- Cost Pressures:Rising raw material costs and currency fluctuations can impact the profitability of Japanese adhesive manufacturers, necessitating efficient production processes and cost management strategies.

Technological Advancements

- Keeping Pace with Innovation:The rapid pace of technological advancement in industries such as electronics and automotive requires adhesive manufacturers to innovate and develop products that continuously meet evolving customer needs.

- Integration with Industry 4.0: As industries embrace digital transformation and Industry 4.0 technologies, adhesive manufacturers must adapt to new production processes and incorporate intelligent technologies into their products.

Future Prospects for the Japanese Adhesive Manufacturing Industry

Despite the challenges, the future of the adhesive manufacturing industry in Japan remains promising, with opportunities for growth and innovation.

Expansion into Emerging Markets

- Asia-Pacific Growth: The Asia-Pacific region presents significant growth opportunities for Japanese adhesive manufacturers, driven by increasing industrialization, urbanization, and infrastructure development.

- Diversification of Applications: Expanding into emerging markets allows Japanese companies to diversify their applications and cater to new industries, such as renewable energy and electric vehicles.

Advancements in Eco-Friendly Adhesives

- Sustainable Solutions: The demand for sustainable adhesives is expected to grow, driven by increasing environmental awareness and regulatory pressures. Japanese manufacturers are well-positioned to lead the development of eco-friendly adhesive solutions.

- Biodegradable Adhesives:The development of biodegradable adhesives offers a promising avenue for growth, providing environmentally friendly alternatives for various applications.

Integration of Smart Technologies

- Smart Adhesive Solutions: Integrating innovative technologies into adhesives presents opportunities for innovation, enabling real-time monitoring and performance optimization in industries such as construction and infrastructure.

- Industry 4.0 Integration: As industries adopt Industry 4.0 technologies, adhesive manufacturers can leverage automation, data analytics, and IoT solutions to enhance production efficiency and product performance.

Collaborations and Partnerships

- Industry Collaborations:Collaborations with other industries, such as automotive, electronics, and healthcare, can drive innovation and create new opportunities for adhesive manufacturers.

- Academic Partnerships: Continued partnerships with educational institutions can facilitate research and development efforts, advance adhesive technology, and drive industry growth.

Conclusion

Conclusion

The adhesive manufacturing industry in Japan is a dynamic and innovative sector that plays a crucial role in supporting various industries’ growth and development. With a rich history of technological advancement, leading companies, and a focus on sustainability, Japan’s adhesive manufacturers are well-positioned to meet future demands. Despite challenges such as environmental regulations and global competition, the industry’s commitment to research and development, eco-friendly solutions, and technological integration promises a bright future. As Japanese adhesive manufacturers continue to innovate and expand into emerging markets, they will remain at the forefront of the global adhesive industry, driving advancements and shaping the future of adhesive technology.

For more about the adhesive manufacturing industry in japan: a comprehensive overview, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.