Silicone Sealant Manufacturers in China: A Growing Industry with Global Impact

Silicone Sealant Manufacturers in China: A Growing Industry with Global Impact

Due to their exceptional durability, flexibility, and resistance to extreme temperatures, silicone sealants have become an essential component in various industries, from construction to automotive. With its large manufacturing base and significant economic growth, China has emerged as a major player in the silicone sealant industry. This article will delve into the current state of silicone sealant manufacturers in China, their products, and their impact on the global market.

History and Development

The silicone sealant industry in China began in the 1980s when the country began to open up to international trade and investment. Initially, the industry focused on producing basic chemicals and materials, but as technology improved and demand for specialized products grew, Chinese manufacturers started to develop and produce silicone sealants. Today, China is home to numerous silicone sealant manufacturers, many of whom have established partnerships with international companies to improve their products and manufacturing processes.

Key Players

Some of the prominent silicone sealant manufacturers in China include:

- BRB Group: A subsidiary of Petronas Chemicals Group, BRB Group is one of China’s largest silicone sealant manufacturers. It offers various silicone sealants for multiple applications, including construction, automotive, and consumer products.

- PCG: Petronas Chemicals Group (PCG) is another significant player in the Chinese silicone sealant industry. PCG’s silicone sealants are known for their high quality and versatility, making them suitable for various industries.

- Bharat Heavy Electricals Limited (BHEL): Although primarily an electrical equipment manufacturer, BHEL also produces silicone sealants for its gas-insulated switchgear products.

Products and Applications

Silicone sealants manufactured in China cater to a wide range of industries and applications, including:

- Construction: Silicone sealants are extensively used in construction projects to seal joints and gaps in buildings, bridges, and other structures. They provide excellent resistance to weathering, UV light, and extreme temperatures.

- Automotive: Silicone sealants are used in the automotive industry to seal and bond various components, such as glass, metal, and plastic. They offer excellent durability and resistance to high temperatures and chemicals.

- Consumer Products: Silicone sealants are used in various consumer products, such as cookware, bakeware, and other household items, due to their non-stick properties and resistance to extreme temperatures.

Impact on the Global Market

The growth of the silicone sealant industry in China has significant implications for the global market:

- Increased Competition: The influx of Chinese silicone sealant manufacturers has increased competition in the global market, leading to improved product quality and reduced prices.

- Global Supply Chain: China’s silicone sealant manufacturers have established partnerships with international companies, enabling them to supply products globally and integrate into global supply chains.

- Technological Advancements: The competition and collaboration between Chinese and international manufacturers have driven technological advancements in silicone sealant production, resulting in improved products and manufacturing processes.

Challenges and Future Outlook

Despite the growth and success of the silicone sealant industry in China, some challenges need to be addressed:

- Environmental Concerns: The production of silicone sealants can have ecological impacts, such as releasing volatile organic compounds (VOCs) and using non-renewable resources. Manufacturers must prioritize sustainability and eco-friendliness in their products and processes.

- Quality Control: The industry’s rapid growth has raised concerns about quality control. Manufacturers must ensure their products meet international standards and regulations to maintain customer trust and confidence.

- Future Outlook: The silicone sealant industry in China is expected to continue growing, driven by increasing demand from various sectors and the need for sustainable and eco-friendly products. To maintain their competitive edge, manufacturers must adapt to changing market trends and customer needs.

Factors To Consider When Choosing A Silicone Sealant Manufacturer In China:

When choosing a silicone sealant manufacturer in China, there are several key factors to consider to ensure you select the right supplier for your needs:

- Quality and Reputation: Evaluate the manufacturer’s reputation and track record. Look for companies known for producing high-quality silicone sealants that meet industry standards and have a history of reliability and customer satisfaction.

- Product Range: Consider the manufacturer’s variety of silicone sealants. A diverse product range indicates flexibility and the ability to cater to different needs and applications.

- Technical Support: Assess the level of customer support provided by the manufacturer. A company that offers excellent technical assistance can help you choose the proper sealant for your specific requirements and provide guidance on application methods.

- Adhesion and Durability: Look for silicone sealants that offer superior adhesion, durability, and resistance to environmental factors. Premium-grade raw materials ensure the sealant’s performance and longevity.

- Compatibility: Verify the compatibility of the silicone sealants with the materials you intend to bond or seal. Ensure the sealant adheres to various surfaces to prevent performance issues and damage.

- Certifications and Standards: Choose a manufacturer that complies with industry standards and certifications related to silicone sealants. This ensures that the products meet quality and safety requirements for your specific applications.

- Cost-effectiveness: Evaluate the cost of the silicone sealants while considering their performance and durability. Opt for a manufacturer that balances quality and cost-effectiveness to avoid future maintenance issues and expenses.

By considering these factors when choosing a silicone sealant manufacturer in China, you can make an informed decision and select a supplier that meets your specific requirements and quality standards.

Typical Applications Of Silicone Sealants In China

Silicone sealants find various applications in China across different industries and sectors, including:

- Construction: Silicone sealants are extensively used in the construction industry in China for applications such as waterproofing, cracks-sealing, and joint-sealing in building and construction activities. They are designed for longevity and ease of application on different substrates, making them essential in construction projects.

- Automotive: In China, silicone sealants are commonly used in the automotive industry for sealing engines, car gaskets, and various components. They provide effective sealing solutions for automotive applications, ensuring durability and resistance to high temperatures and chemicals.

- Healthcare: Silicone sealants are utilized in healthcare applications in China to assemble and seal medical device parts. They play a crucial role in ensuring the integrity and safety of medical equipment by providing secure seals and protection against environmental factors.

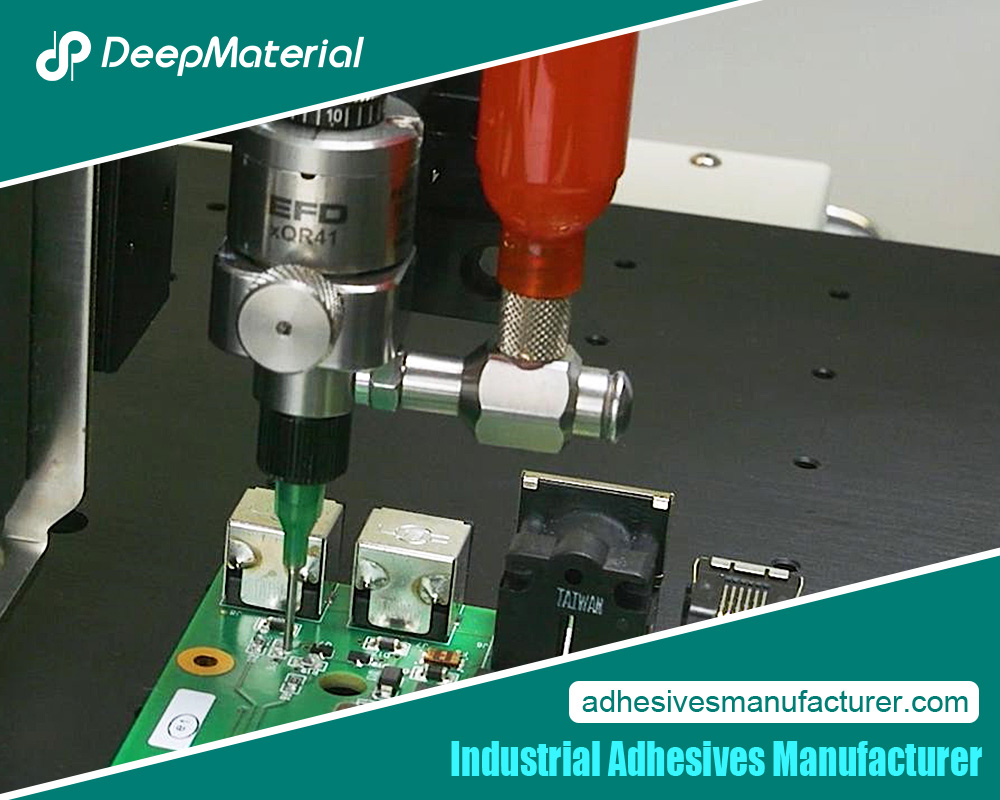

- Electronics: The Chinese electronics market also benefits from silicone sealants used for potting and protecting applications in electrical equipment manufacturing. They are crucial for sealing sensors, cables, and other components, contributing to the reliability and longevity of electronic devices.

- Other Industries: In addition to the mentioned sectors, silicone sealants in China have diverse applications in aerospace, household appliances, and various manufacturing processes. Their versatility, durability, and resistance to environmental factors make them valuable across multiple applications and industries.

By catering to these diverse applications in China, silicone sealants are vital in ensuring the integrity, longevity, and performance of various products and structures across different sectors.

In conclusion, the silicone sealant industry in China has experienced significant growth and development over the years, driven by the country’s large manufacturing base and economic growth. The industry’s key players, such as BRB Group and PCG, offer a wide range of silicone sealants for various applications, and their products significantly impact the global market. While challenges must be addressed, the industry’s future outlook remains promising, focusing on sustainability, quality control, and adapting to changing market trends.

For more about the best silicone sealant manufacturers in china: a growing industry with global impact, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.