Revolutionizing Electronics: The Role of Electronic Potting Compounds Manufacturer

Revolutionizing Electronics: The Role of Electronic Potting Compounds Manufacturer

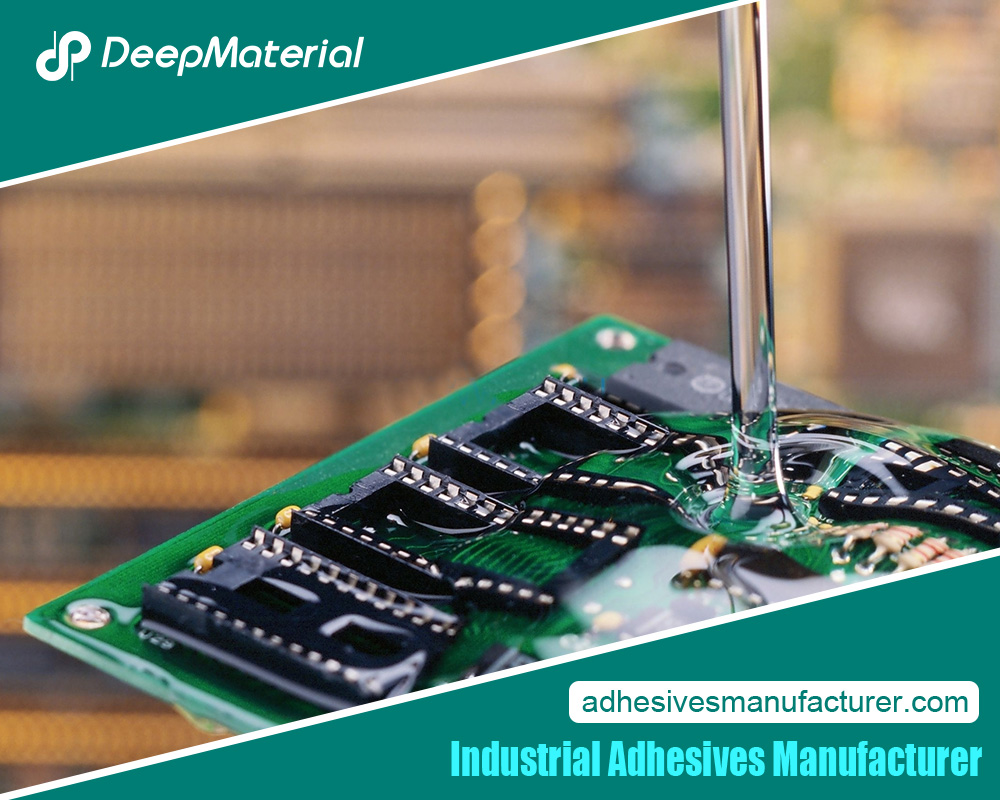

Electronic potting compounds are a small but vital component in the complex world of electronics, where accuracy and robustness are critical. These compounds protect electronic devices from environmental risks, mechanical strain, and electrical interference. They are produced by specialized companies called Electronic Potting Compounds Manufacturers. This article examines the unique advancements made by manufacturers in electronic potting compounds and delves into their significance.

Understanding Electronic Potting Compounds:

Electronic potting compounds are materials used to encapsulate or pot electronic assemblies. They improve the performance and lifespan of sensitive electronic components while shielding them from the elements and other potential hazards, including vibration, moisture, and dust. Usually composed of silicone, epoxy, polyurethane, or other polymers, these compounds have unique qualities appropriate for various uses.

The Significance of Electronic Potting Compounds:

- Protection:Electronic potting compounds provide a protective barrier around electronic components, shielding them from environmental factors such as moisture, dust, and vibrations.

- Insulation:These compounds act as excellent insulators, preventing electrical short circuits and ensuring the safe operation of electronic devices.

- Thermal Management:Electronic potting compounds can also help dissipate heat generated by electronic components, improving their overall performance and reliability.

- Enhanced Durability:These compounds improve the durability and resistance to mechanical stress of electronic components by encapsulating them, extending the lifespan of devices.

The Manufacturing Process of Electronic Potting Compounds:

- Formulation:Electronic potting compounds are typically formulated using a combination of epoxy resins, hardeners, fillers, and additives to achieve the desired properties, such as flexibility, thermal conductivity, and flame retardancy.

- Mixing:The ingredients are carefully mixed in precise proportions to ensure uniformity and consistency in the final product.

- Degassing:The mixture is then degassed to remove any air bubbles, which can affect the performance and appearance of the potting compound.

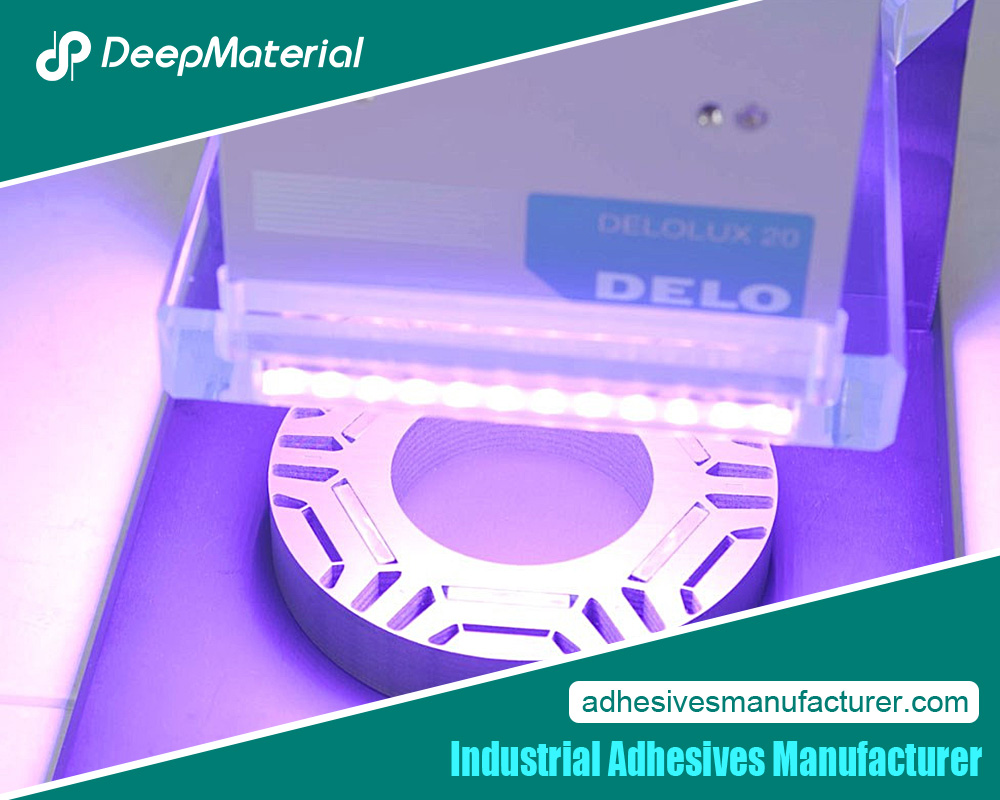

- Curing:The mixed compound is cured at elevated temperatures to initiate the chemical reaction that transforms it from liquid to solid.

- Testing:The cured compound undergoes rigorous testing to ensure it meets the required specifications for performance and reliability.

The Role of Electronic Potting Compounds Manufacturer:

Electronic potting compound producers play a crucial role in electronic gadgets, where dependability and performance are essential. These manufacturers are critical to improving the performance and longevity of electronic components because they offer customized formulations, strict quality control procedures, and customization choices. Let’s examine the salient features of their input:

Tailored Formulations:

- Based on the intended application, electronic potting compound manufacturers formulate materials to meet specific requirements, such as thermal conductivity, flame retardancy, or flexibility.

- By understanding the unique demands of different industries and applications, they create formulations that optimize the performance and longevity of electronic components.

Customization:

- They provide customization options, allowing clients to choose properties like viscosity, curing time, and color tailored to their precise needs.

- This level of customization ensures that the potting compounds seamlessly integrate into the manufacturing process, enhancing efficiency and effectiveness.

Research and Development (R&D):

- These manufacturers invest in R&D to innovate new formulations, incorporating advanced materials and techniques to enhance the performance and reliability of electronic devices.

- By staying at the forefront of technological advancements, they continuously improve their products to meet the evolving needs of the electronics industry.

Quality Assurance:

- Electronic potting compound manufacturers adhere to stringent quality control measures to ensure product consistency and reliability and meet industry standards and regulations.

- Through rigorous testing and quality assurance protocols, they guarantee that their products deliver the expected performance and durability, fostering trust among clients and consumers.

Innovations in Electronic Potting Compounds Manufacturing:

Ensuring the robustness and dependability of electronic components is crucial in the rapidly evolving field of electronics. Electronic potting compounds are essential to shield these components from external elements, mechanical strain, and thermal shock. Producing potting compounds requires creative ways to keep up with technological advancements. Let’s examine some of this industry’s most recent developments and trends.

Eco-Friendly Formulations

- Bio-Based Materials:Manufacturers are increasingly turning to bio-based materials derived from renewable sources to reduce the environmental impact of electronic waste.

- Recyclable Compounds: Recycling electronic components is becoming more feasible with the development of recyclable potting compounds, further reducing the carbon footprint of electronic devices.

Nanotechnology Integration

- Nanocomposite Materials:By incorporating nanoparticles into potting compounds, manufacturers can enhance thermal conductivity, mechanical strength, and other crucial properties for high-performance electronics.

- Improved Performance:Nanotechnology enables potting compounds to withstand extreme conditions, making them ideal for demanding applications in aerospace, automotive, and industrial electronics.

Self-Healing Compounds

- Polymer Innovation:Researchers are exploring self-healing polymers that can autonomously repair minor damages, extending the lifespan of electronic assemblies and reducing maintenance costs.

- Enhanced Reliability:Self-healing compounds offer improved reliability, ensuring continuous operation of electronic devices even in harsh environments.

Smart Potting Compounds

- Real-Time Monitoring:Incorporating sensors or additives into potting compounds allows for real-time monitoring of environmental conditions, such as temperature or humidity.

- Proactive Protection:Smart potting compounds protect electronic components proactively, alerting users to potential issues before they escalate.

Benefits of Electronic Potting Compounds:

Electronic potting compounds protect electronic assemblies, ensuring their longevity and reliability. These compounds offer a range of benefits, from enhancing durability to improving performance, making them essential in various industries. Let’s explore the key advantages of using electronic potting compounds.

Enhanced Durability:

- Protection from Environmental Factors:Potting compounds shield electronic assemblies from moisture, dust, and corrosion, preventing damage caused by environmental factors.

- Mechanical Stress Resistance:These compounds provide mechanical support, reducing the risk of damage due to vibration or impact, thereby extending the lifespan of electronic devices.

Improved Performance:

- Thermal Management:Electronic potting compounds help dissipate heat generated by electronic components, preventing overheating and ensuring optimal performance.

- Electrical Insulation:By insulating components, these compounds prevent short circuits and electrical failures, enhancing the reliability of electronic devices.

- Vibration Dampening:Potting compounds reduce vibrations, improving the performance and accuracy of sensitive electronic components.

Cost Savings:

- Prolonged Lifespan:By protecting electronic assemblies from premature failure, potting compounds help extend the lifespan of electronic products, reducing the need for frequent replacements.

- Minimized Maintenance:Using potting compounds can reduce maintenance requirements, saving time and money over the lifecycle of electronic devices.

Versatility:

- Cross-Industry Application:Electronic potting compounds find applications in various industries, including automotive, aerospace, medical devices, and consumer electronics, offering versatile solutions for diverse electronic applications.

- Compatibility with Different Substrates:These compounds are compatible with various substrates, including metals, plastics, and ceramics, making them suitable for multiple electronic assemblies.

Conclusion

As technology develops, there is an exponential increase in demand for sturdy and dependable electrical components. Manufactured by specialized companies, electronic potting compounds guarantee electronic equipment’s performance, endurance, and robustness in various applications. Electronic potting compound manufacturers are propelling the progress of electronics through constant innovation and customization, opening the door to the creation of future electronic systems that are more robust and effective.

For more about revolutionizing electronics: the role of electronic potting compounds manufacturer, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.