Plastic Bonding Adhesives Market: Trends, Growth, and Opportunities

Plastic Bonding Adhesives Market: Trends, Growth, and Opportunities

The increasing demand for lightweight, durable, and cost-effective materials has made plastic bonding adhesives an integral part of various industries, from automotive and electronics to packaging and construction. Plastic or structural adhesives bond plastics with other materials, offering superior strength, resistance to harsh environments, and excellent performance over time. As industries continue to evolve and the demand for advanced bonding solutions grows, the global plastic bonding adhesives market is witnessing significant growth. This article will explore the market trends, key drivers, challenges, and opportunities in the plastic bonding adhesives sector, providing a comprehensive overview of the industry’s current landscape.

Market Overview

The plastic bonding adhesives market has expanded rapidly over the past few years, driven by technological advancements in adhesive formulations and the growing need for strong, reliable connections in various industries. These adhesives are used for bonding plastics like polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and others, which are often challenging to bond with traditional methods like mechanical fastening or welding.

Key Types of Plastic Bonding Adhesives

Several plastic bonding adhesives are available in the market, each with specific advantages based on the application requirements. Some common types include:

- Epoxy Adhesives:Known for their exceptional bonding strength and resistance to heat and chemicals.

- Acrylic Adhesives:Provide strong adhesion to various plastics, offering excellent environmental resistance.

- Polyurethane Adhesives: Flexible and durable, ideal for bonding plastics in automotive applications.

- Silicone Adhesives: Offer high flexibility, weather resistance, and temperature stability, making them suitable for the construction and electronics industries.

- Cyanoacrylate Adhesives:Also known as “superglue,” these adhesives provide instant bonding and are ideal for small-scale applications.

Key Drivers of Market Growth

Several factors are driving the growth of the plastic bonding adhesives market. These include the increasing demand for lightweight materials, the need for sustainable and efficient bonding solutions, and the rise of advanced manufacturing technologies.

Growing Demand in Automotive Industry

The automotive industry is one of the largest consumers of plastic bonding adhesives. Automakers seek lightweight, durable, cost-effective solutions to reduce vehicle weight and improve fuel efficiency. Plastic bonding adhesives are used in various automotive applications, including interior and exterior components, electrical systems, and structural parts.

- Using plastic bonding adhesives helps reduce the need for mechanical fasteners, which can increase weight and lead to higher production costs.

- These adhesives also offer enhanced durability and resistance to environmental factors like moisture, heat, and chemicals, making them ideal for automotive parts exposed to harsh conditions.

Rising Demand for Electronics and Consumer Goods

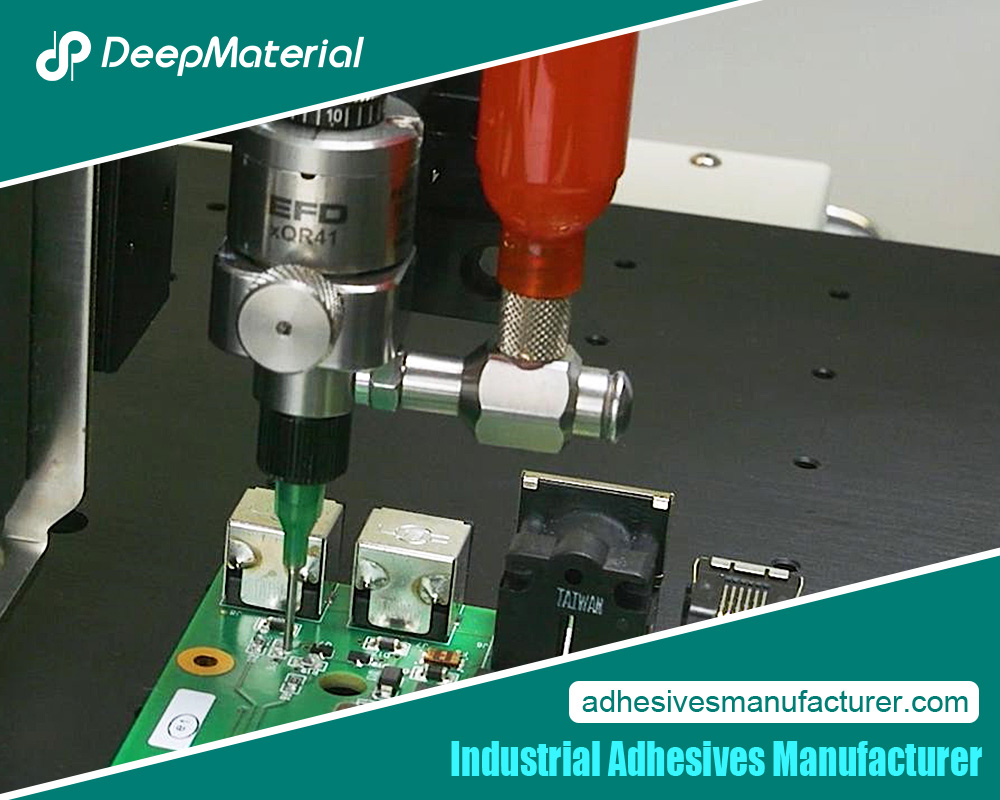

The increasing reliance on electronics and consumer goods is another factor fueling the growth of the plastic bonding adhesives market. With the rise of mobile devices, laptops, and other electronic products, manufacturers need strong, reliable bonding solutions to secure components like displays, buttons, and covers. Plastic bonding adhesives offer high performance, ensuring that products are durable and long-lasting.

- Adhesives used in electronics must withstand extreme temperatures, shock, and vibration, which plastic bonding adhesives can deliver.

- The increasing miniaturization of electronic devices has created a need for adhesives that can bond small and intricate parts, making them essential for the industry.

Advancements in Manufacturing Technologies

Innovations in adhesive formulations and manufacturing technologies have significantly expanded the plastic bonding adhesives market. Advancements such as the development of UV-curable adhesives, improved curing systems, and nanomaterials have enhanced the performance and versatility of these adhesives, making them suitable for a broader range of applications.

- UV-curable adhesives offer faster curing times, making them ideal for high-speed production lines.

- Incorporating nanomaterials into adhesive formulations enhances bonding strength and provides additional benefits such as increased wear resistance and improved thermal stability.

Market Challenges

Despite its growth potential, the plastic bonding adhesives market faces several challenges that must be addressed for sustained expansion.

Adhesion Issues with Certain Plastics

One of the main challenges in the plastic bonding adhesives market is the difficulty bonding certain plastics, particularly low-surface-energy plastics like polyethylene (PE) and polypropylene (PP). These plastics are resistant to adhesive bonding due to their non-polar surfaces, which make it hard for adhesives to establish a strong bond.

- Manufacturers are developing specialized surface treatment techniques and new adhesive formulations to address this issue.

- Surface treatments such as plasma, flame, or corona discharge are commonly used to improve adhesion on difficult-to-bond plastics.

Environmental Concerns and Regulations

The growing emphasis on sustainability and environmental protection pushes industries to adopt eco-friendly adhesive solutions. Traditional adhesives may contain harmful chemicals, such as volatile organic compounds (VOCs), which pose health and environmental risks.

- The demand for low-VOC and non-toxic adhesives is increasing, pushing manufacturers to develop greener adhesive formulations.

- Regulatory frameworks worldwide are becoming stricter, requiring companies to comply with stringent environmental standards, which can impact the development and production of certain adhesives.

Cost of Raw Materials

The cost of raw materials used to produce plastic bonding adhesives can fluctuate, affecting the overall price of these adhesives. Global supply chain disruptions can influence the prices of key raw materials, such as resins and curing agents, leading to increased production costs.

- Manufacturers are exploring cost-effective raw material alternatives to mitigate the impact of price volatility.

- Developing recyclable and biodegradable adhesives is also gaining traction as companies seek to reduce their products’ environmental impact.

Opportunities in the Plastic Bonding Adhesives Market

The plastic bonding adhesives market presents several growth opportunities, especially in emerging markets and industries.

Expansion in Emerging Markets

Emerging markets, particularly in Asia-Pacific and Latin America, present significant opportunities for growth in the plastic bonding adhesives market. As industrialization and urbanization continue to accelerate in these regions, there is an increasing demand for plastic bonding adhesives in the automotive, electronics, construction, and packaging industries.

- The automotive sector is rapidly expanding in countries like China and India, driving demand for lightweight materials and advanced bonding solutions.

- The electronics industry in these regions is also booming, creating a need for high-performance adhesives to bond plastic components in consumer electronics.

Development of Eco-Friendly Adhesives

As sustainability becomes a top priority for businesses worldwide, developing eco-friendly plastic bonding adhesives represents a significant growth opportunity. Manufacturers focus on creating adhesives that have minimal environmental impact without compromising performance.

- Biodegradable adhesives and water-based formulations are gaining traction, offering a more sustainable alternative to traditional adhesives.

- Developing recyclable and reusable adhesives could reduce waste and contribute to the circular economy.

Customization and Tailored Solutions

There is also a growing demand for customized plastic bonding adhesive solutions that meet the specific needs of various industries. Manufacturers offer tailor-made adhesive products designed to meet the unique requirements of different applications, including particular bonding challenges, environmental conditions, and performance standards.

- Companies that can offer highly specialized and application-specific adhesive solutions are well-positioned to capture market share in niche sectors.

- This trend is particularly evident in the automotive and electronics industries, where precision bonding is crucial for performance and safety.

Conclusion

The plastic bonding adhesives market is experiencing robust growth driven by the increasing demand for lightweight, durable, and sustainable solutions across various industries. Technological advancements, a growing focus on eco-friendly products, and the rising need for high-performance adhesives in sectors like automotive, electronics, and packaging contribute to the market’s expansion. However, challenges such as adhesion issues with certain plastics and environmental regulations must be addressed for continued growth. With ample opportunities in emerging markets and the development of customized and eco-friendly adhesives, the future of the plastic bonding adhesives market looks promising.

For more about a complete guide to plastic bonding adhesives market: trends, growth, and opportunities, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.