Plastic Bonding Adhesives Market: Growth, Trends, and Key Insights

Plastic Bonding Adhesives Market: Growth, Trends, and Key Insights

The global plastic bonding adhesives market has grown significantly in recent years, driven by an increasing demand for lightweight, durable, and cost-effective bonding solutions across various industries. As automotive, aerospace, electronics, and construction industries continue to innovate and seek more efficient production methods, the need for reliable adhesive solutions has become more apparent. Plastic bonding adhesives offer a versatile, robust, and flexible solution for various applications.

This article will explore the plastic bonding adhesives market, its growth factors, major applications, technological advancements, and future trends. The report will also touch on regional analysis, leading players, and the challenges faced by the industry.

Market Overview

Definition and Scope

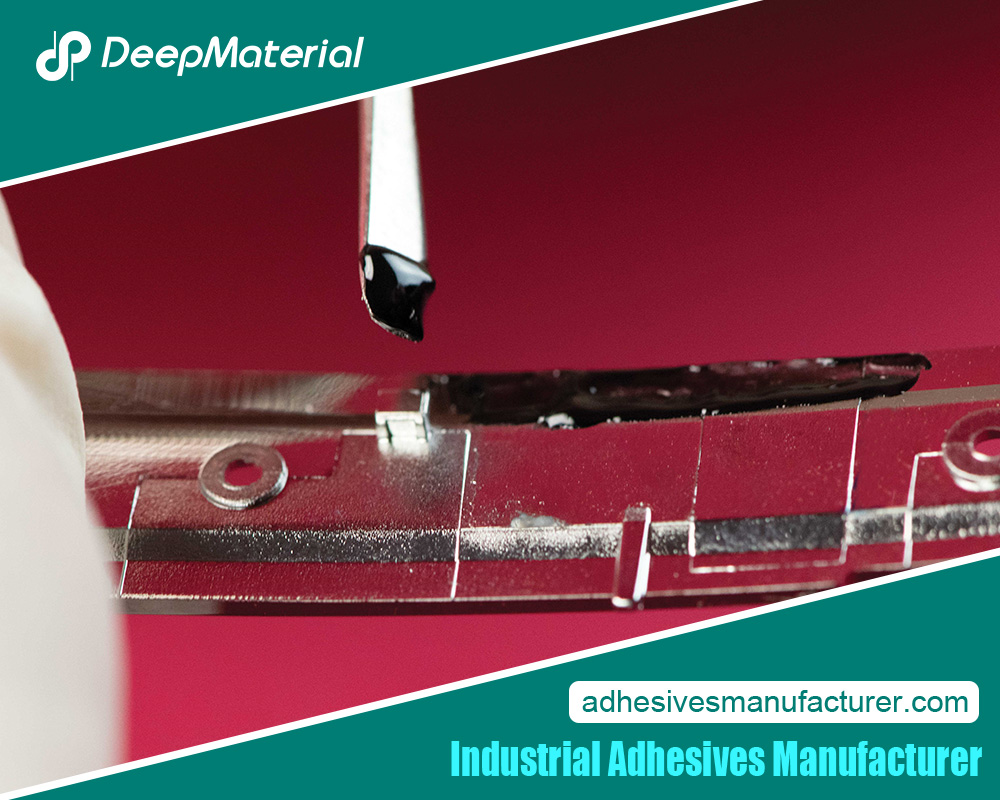

Plastic bonding adhesives are specialised adhesives that combine different plastics or plastics with other materials such as metals, ceramics, or glass. These adhesives play a crucial role in replacing traditional mechanical fasteners like screws, rivets, or welding in various applications. The critical advantage of plastic adhesives is their ability to bond materials without compromising structural integrity while maintaining flexibility, weather resistance, and long-term durability.

Types of Plastic Bonding Adhesives

Plastic bonding adhesives are classified into various types based on their composition and bonding mechanisms. The most common types include:

- Epoxy adhesives:Known for their strong bonding properties and high resistance to chemicals and temperature, epoxy adhesives are widely used in industries requiring durable and long-lasting bonds.

- Acrylic adhesives:Acrylic adhesives offer fast bonding and are well-suited for bonding different types of plastics, such as PVC, polycarbonate, and acrylic. These adhesives are famous for their UV resistance and strength.

- Polyurethane adhesives:Polyurethane adhesives are flexible and provide excellent adhesion to various plastic surfaces. They are commonly used in automotive and construction applications that require flexibility and impact resistance.

- Cyanoacrylate adhesives:Also known as instant adhesives or superglues, cyanoacrylates provide rapid bonding with strong adhesion, making them suitable for small and intricate parts.

Market Size and Growth

The global plastic bonding adhesives market was valued at approximately USD 6.5 billion in 2021, with a projected compound annual growth rate (CAGR) of 7.8% from 2022 to 2030. This growth is driven by the increasing adoption of plastic materials in various industries and the growing trend toward replacing traditional fasteners with adhesives for lightweight and streamlined designs.

Key Market Drivers

Several factors have contributed to the expansion of the plastic bonding adhesives market. The following are some of the primary drivers:

Rising Demand in the Automotive Industry

The automotive sector is a major consumer of plastic bonding adhesives. As automakers focus on reducing vehicle weight to enhance fuel efficiency and meet stricter environmental regulations, the use of lightweight plastic components has become more prevalent. Adhesives are critical in joining plastic components to metal or other plastic parts, replacing traditional fastening methods. This shift is fueling the demand for adhesives that offer strong bonding while ensuring flexibility, heat resistance, and vibration absorption.

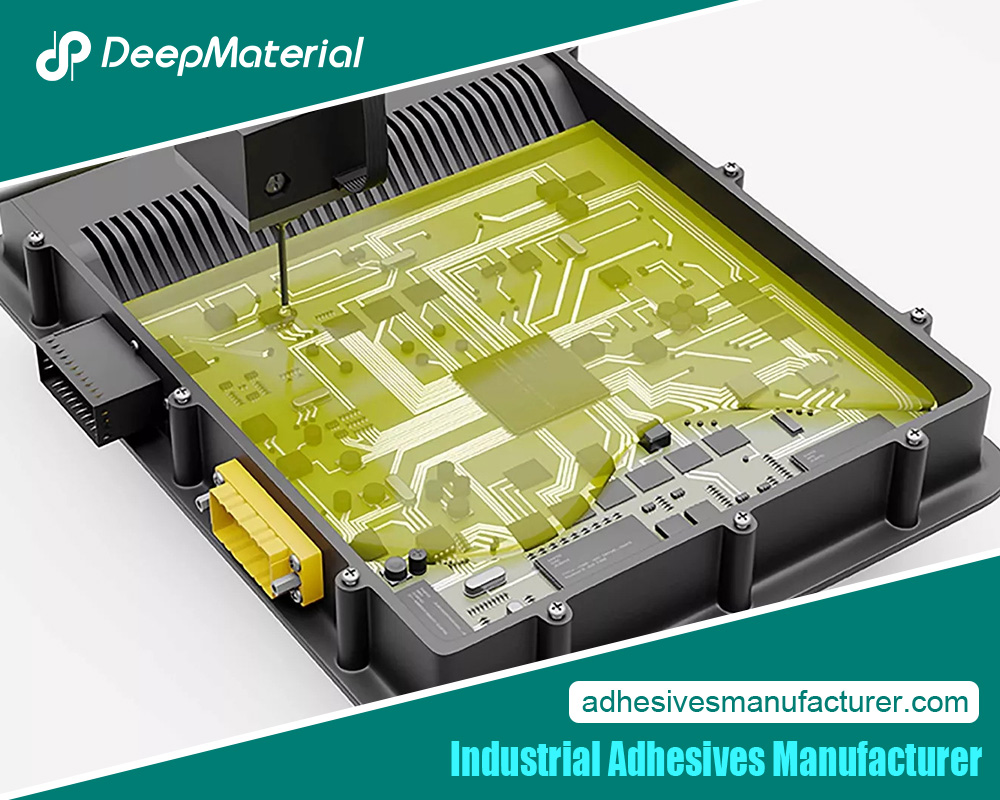

Advancements in Consumer Electronics

The consumer electronics industry is another critical plastic bonding adhesives market driver. Modern devices like smartphones, tablets, and wearables often require compact designs with plastic and glass components. Adhesives that can bond these materials without adding bulk or compromising design are essential for product manufacturers. As consumer demand for thinner, more lightweight devices grows, so too does the need for high-performance adhesives.

Growth in the Construction Industry

In the construction industry, plastic materials are increasingly used for window frames, pipes, cladding, and insulation. Plastic bonding adhesives are favoured for their ability to provide durable, weather-resistant seals and joints in these applications. The demand for eco-friendly construction materials and energy-efficient solutions is also driving the growth of this market as contractors look for adhesives that can bond various substrates while contributing to sustainability goals.

Sustainability and Eco-Friendly Solutions

Sustainability and Eco-Friendly Solutions

Sustainability has become a key focus across industries, and plastic bonding adhesives are no exception. Manufacturers are now developing adhesives with lower volatile organic compound (VOC) emissions, biodegradable formulations, and increased energy efficiency in production processes. These eco-friendly alternatives are gaining traction in markets where regulatory standards and environmental awareness are on the rise.

Challenges and Constraints

While the plastic bonding adhesives market has seen considerable growth, it faces several challenges:

Volatility in Raw Material Prices

The cost of raw materials used in adhesive production, such as petroleum-based chemicals, can be volatile. Fluctuations in crude oil prices and supply chain disruptions can impact the pricing and availability of these materials. Adhesive manufacturers often face pressure to maintain competitive pricing while managing raw material costs, affecting profit margins.

Stringent Environmental Regulations

The production of plastic bonding adhesives often involves using chemicals that emit VOCs, which contribute to air pollution and pose health risks. As governments worldwide tighten regulations on VOC emissions and hazardous chemicals, adhesive manufacturers must develop environmentally friendly alternatives. While this shift presents growth opportunities, it also increases the cost and complexity of research and development.

Compatibility Issues

Not all plastic bonding adhesives are compatible with every type of plastic or substrate. Some plastics, such as polyethylene and polypropylene, are relatively easy to bond with unique surface treatments or primers. This limitation can restrict certain adhesives in specific applications, requiring manufacturers to develop tailored solutions for different plastic types.

Regional Market Insights

The plastic bonding adhesives market is segmented by region, with varying levels of demand and growth across different areas:

North America

North America remains a leading market for plastic bonding adhesives due to the presence of major industries such as automotive, aerospace, and electronics. The United States, in particular, is home to some of the largest adhesive manufacturers and innovation centres. The growing adoption of electric vehicles (EVs) and the demand for lightweight materials in the automotive industry are expected to drive further growth in this region.

Europe

Europe is another significant market, with Germany, France, and the UK leading the charge in automotive production and innovation. European regulations around VOC emissions and environmental sustainability have pushed adhesive manufacturers to develop eco-friendly products, further driving market growth. The region also sees increasing demand for adhesives in renewable energy applications, such as wind turbines and solar panels.

Asia-Pacific

The Asia-Pacific region is the fastest-growing market for plastic bonding adhesives, with China, Japan, and South Korea significant players. This region’s rapid industrialization and urbanisation have fueled the demand for adhesives across the construction, electronics, and automotive sectors. In particular, China’s burgeoning electric vehicle market presents significant growth opportunities for adhesive manufacturers.

Rest of the World

In regions such as Latin America, the Middle East, and Africa, the plastic bonding adhesives market is growing steadily, albeit slower than in developed economies. The expansion of the construction sector and increasing investments in infrastructure development are expected to boost demand for adhesives in these regions.

Key Players and Competitive Landscape

The plastic bonding adhesives market is highly competitive, with several global and regional players vying for market share. Key manufacturers include:

- 3M Company: A leading player in the adhesive industry, 3M offers various plastic bonding adhesives for industrial and consumer applications.

- Henkel AG & Co. KGaA: Known for its innovative adhesive solutions, Henkel serves various industries, including automotive, electronics, and construction.

- Sika AG: Sika is a major supplier of construction adhesives and sealants, with a focus on sustainability and energy-efficient solutions.

- B. Fuller: H.B. Fuller specialises in industrial and consumer applications adhesives, with a strong presence in the packaging and electronics sectors.

- DowDuPont Inc.: A key player in the chemical industry, DowDuPont offers advanced adhesive solutions for various industries, including transportation and electronics.

Future Trends and Outlook

The future of the plastic bonding adhesives market looks promising, with several trends shaping its trajectory:

- Increased Adoption of Electric Vehicles: As the global shift toward electric vehicles accelerates, adhesive manufacturers are developing products that cater specifically to the unique requirements of EV production, such as thermal management and lightweight bonding.

- Advancements in Adhesive Technology: Ongoing research and development efforts are leading to the creation of adhesives with enhanced properties, such as faster curing times, higher strength, and improved resistance to environmental factors.

- Sustainability Initiatives: The demand for eco-friendly adhesives will continue rising as industries prioritise sustainability and green manufacturing practices.

- Innovative Adhesives: Developing intelligent adhesives with embedded sensors or self-healing properties could revolutionise industries such as aerospace and electronics, offering enhanced functionality and longevity.

Conclusion

The plastic bonding adhesives market is poised for substantial growth, driven by technological advancements, increasing demand for lightweight and durable materials, and the rise of eco-friendly solutions. While challenges such as raw material price volatility and regulatory pressures remain, the market’s future is bright, with numerous opportunities for innovation and expansion across industries. As manufacturers continue to refine their adhesive formulations and expand into new markets, plastic-bonding adhesives will remain a critical component of modern manufacturing and design.

For more about a complete guide to plastic bonding adhesives market: growth, trends, and key insights, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.