Navigating the Landscape of Electronic Potting Silicone Manufacturers in China

Navigating the Landscape of Electronic Potting Silicone Manufacturers in China

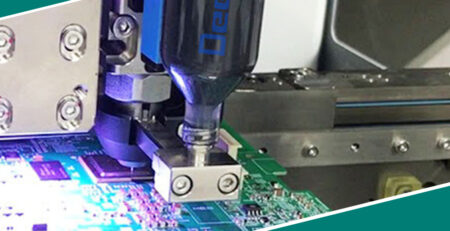

In the dynamic world of electronics, the quest for optimal protection and durability is paramount. Electronic potting silicone, a crucial material in this regard, serves as a protective coating that enhances the longevity and performance of electronic components. In China, the epicenter of global manufacturing, numerous companies specialize in producing high-quality electronic potting silicone. This article explores the critical considerations for navigating the landscape of electronic potting silicone manufacturers in China, examining their roles, benefits, and the factors that set them apart in a competitive market.

Understanding Electronic Potting Silicone

Electronic potting silicone is a resin that encases and protects electronic components from environmental factors such as moisture, dust, and temperature fluctuations. The potting process involves filling the voids within electronic assemblies with silicone material and curing them to form a solid, protective layer. This layer shields the components and provides insulation and mechanical support.

Critical Benefits of Electronic Potting Silicone

Electronic potting silicone, especially from manufacturers in China, plays a pivotal role in enhancing the durability and reliability of electronic devices. Here’s a detailed look at the key benefits:

- Enhanced Protection: Electronic potting silicone provides exceptional resistance to moisture, chemicals, and extreme temperatures. This level of protection is crucial for safeguarding electronic components from environmental factors that could otherwise lead to device failure. By creating a robust barrier, silicone potting ensures the longevity of electronics, even in the most challenging conditions.

- Electrical Insulation: Silicone potting materials offer outstanding electrical insulation properties. This feature is vital for minimizing the risk of short circuits and electrical failures. By isolating electrical components from each other and external conductive materials, silicone potting helps maintain consistent performance and safety in electronic devices.

- Vibration Dampening: One significant advantage of silicone potting is its ability to absorb and dissipate vibrations. Electronic devices are often subjected to mechanical shocks and vibrations, which can damage sensitive components. Silicone’s inherent cushioning effect reduces the impact of these vibrations, thereby preventing potential mechanical damage and extending the device’s lifespan.

- Thermal Stability: Silicone potting maintains its protective qualities across a broad temperature range. Silicone retains its performance attributes whether exposed to high heat or extreme cold. This thermal stability ensures that electronic devices remain protected and operational regardless of temperature fluctuations, making them suitable for various applications and environments.

Electronic potting silicone manufacturers in China are known for producing high-quality materials that leverage these benefits to enhance the performance and durability of electronic devices. By incorporating these potting solutions, manufacturers and developers can ensure that their products are resilient, reliable, and ready to meet the demands of modern technology.

Factors Influencing the Choice of Manufacturers

Factors Influencing the Choice of Manufacturers

Several factors come into play when selecting an electronic potting silicone manufacturer in China. Understanding these factors can help buyers make informed decisions and choose a manufacturer that best meets their needs.

Quality of Materials

The quality of silicone used in potting applications directly affects the performance and reliability of electronic devices. Manufacturers in China offer a range of silicone formulations, including:

- Standard Silicone: Suitable for general applications where essential protection is required.

- High-Performance Silicone:Designed for extreme conditions, offering enhanced resistance to temperature fluctuations and environmental stress.

- Custom Formulations: These are tailored to specific application needs and provide unique properties, such as improved flexibility or enhanced chemical resistance.

Production Capabilities

Manufacturers’ production capabilities are crucial in determining their ability to meet demand and maintain product consistency. Key aspects include:

- Manufacturing Scale: The manufacturing facility’s size and scope can impact the production volume and turnaround times.

- Technological Advancements: Modern production techniques and equipment contribute to higher quality and more reliable silicone products.

- Quality Control:Rigorous quality control processes ensure that the silicone meets industry standards and performs as expected.

Regulatory Compliance

Compliance with international standards and regulations is essential for manufacturers to ensure their products are safe and effective. Look for manufacturers that adhere to:

- RoHS (Restriction of Hazardous Substances): Ensuring products are free from hazardous materials.

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Compliance with European Union regulations on chemical safety.

- ISO Certifications:Indicating adherence to quality management and environmental standards.

Cost and Pricing

Cost is always a consideration, but it should be weighed alongside quality and performance. Factors affecting pricing include:

- Raw Material Costs: Variations in the cost of raw materials can impact overall pricing.

- Production Efficiency:Manufacturers with streamlined production processes may offer more competitive pricing.

- Order Volume: Bulk orders often result in cost savings, making negotiating pricing based on projected demand beneficial.

Customer Support and Service

Adequate customer support is vital for addressing any issues or concerns that may arise. Evaluate manufacturers based on the following:

- Responsiveness: Timely communication and support during and after the purchase process.

- Technical Assistance: Technical support is available for troubleshooting and guidance on product use.

- Flexibility: Willingness to accommodate custom orders or adjust formulations based on specific requirements.

Trends and Innovations in Electronic Potting Silicone

The industry of electronic potting silicone is evolving, with manufacturers continuously developing new solutions to meet emerging demands. Notable trends and innovations include:

Advanced Formulations

Manufacturers are developing advanced silicone formulations with enhanced properties, such as:

- Self-Healing Silicones: Capable of repairing minor damages automatically, extending the product’s lifespan.

- Thermal Conductive Silicones: Improving heat dissipation for high-performance electronic devices.

Eco-Friendly Solutions

Sustainability is becoming increasingly important. Manufacturers are exploring eco-friendly options, such as:

- Bio-Based Silicones:Derived from renewable resources to reduce environmental impact.

- Reduced VOC (Volatile Organic Compounds): Minimizing harmful emissions during production and application.

Smart Integration

The integration of intelligent technologies into potting silicone applications is on the rise, including:

- Embedded Sensors: Monitoring environmental conditions within electronic assemblies.

- Self-Sensing Materials:Providing real-time data on the condition of the potting material and the protected components.

Conclusion

Conclusion

The landscape of electronic potting silicone manufacturers in China is diverse and dynamic, offering a range of products and solutions to meet the evolving needs of the electronics industry. Buyers can make informed decisions and partner with manufacturers that align with their requirements by focusing on factors such as material quality, production capabilities, regulatory compliance, cost, and customer support. As the industry continues to innovate, staying abreast of trends and advancements will be crucial for leveraging the full potential of electronic potting silicone in protecting and enhancing electronic devices. With careful consideration and strategic selection, manufacturers and buyers alike can contribute to advancing technology and improving electronic reliability and performance.

For more about navigating the landscape of electronic potting silicone manufacturers in china, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.