Key Factors to Consider When Scaling Up Production with a Conformal Coating Material Manufacturer

Key Factors to Consider When Scaling Up Production with a Conformal Coating Material Manufacturer

Protective coatings for electronics and printed circuit boards are known as conformal coating materials. They’re an absolute must in the manufacturing process because they shield devices against moisture, dust, harsh chemicals, or temperature shifts that could damage them in the long run.

Conformal coat material producers are a vital part of the electronic industry. They meet manufacturer needs by supplying top-tier finishes – you’ve got acrylics with their durability characteristics; silicones plus their waterproofing goodness; urethanes for superb resistance to abrasion; and epoxies to offer strength (and beauty). In short, no matter what your application calls for – they have just the right option.

Understanding the Importance of Scaling Up Production

Scaling up production is an important task for electronics factories; it solidifies their spot in the market by keeping them ahead of rising demand. By cranking things up, they can churn out a higher volume of electronic devices within less time–which leads to nicer profits and satisfied customers.

Teaming up with a conformal coating material supplier has its perks when scaling your output – they have all the know-how and stuff you need, from necessary equipment to facilities and personnel who are experienced in producing large quantities quickly plus effectively. Not only that, but these suppliers provide technical assistance throughout the whole operation, too: guaranteeing that those coatings keep their quality intact!

Quality Control Measures for Conformal Coating Material

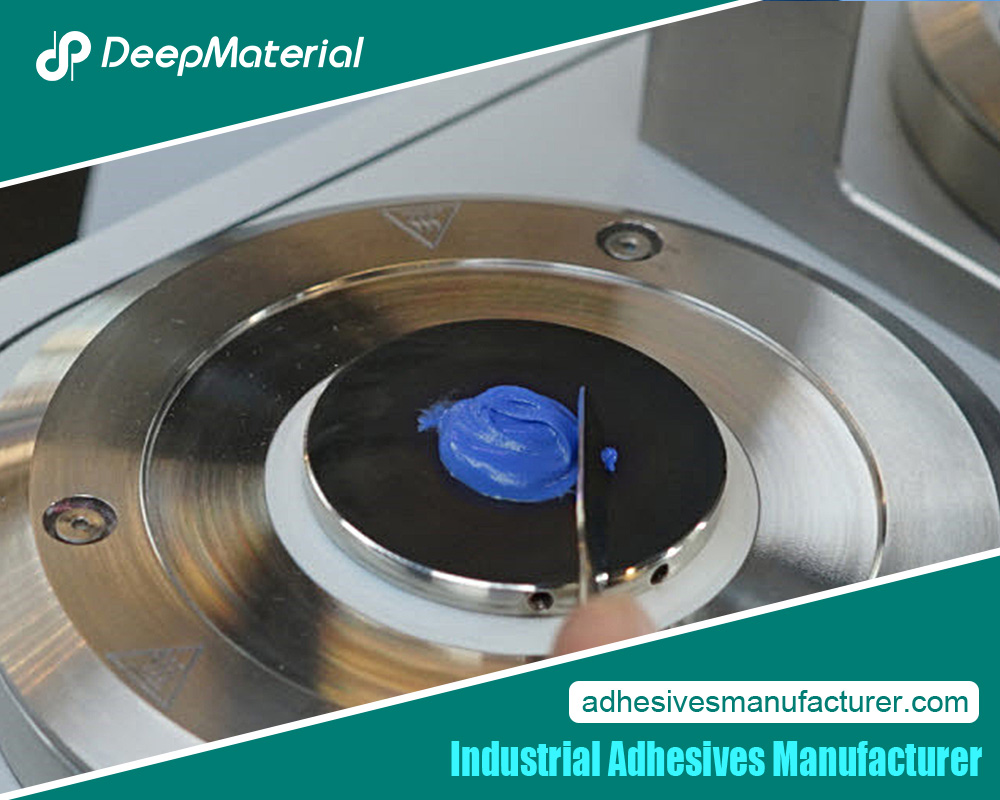

Quality control is vital when it comes to the manufacturing process; we must make sure that our conformal coating material lives up to the set standards and specs. We need these measures in place to keep an eye out for any discrepancies or issues with the material before it is applied to electronic parts. Speaking of quality control for this stuff, here’s a few specific pointers you should remember:

Raw material inspection

The manufacturer needs to really dig deep into inspecting all the raw materials used in creating that coating material, guaranteeing its quality and dependability. No corners cut here! Let’s make sure every inch is checked over – we can’t risk anything slipping through the cracks.

In-process inspections

it’s super important to keep an eye out during the manufacturing process for any imperfections or abnormalities. A few ways to do this would be visual checks, checking viscosity levels, and doing some adhesive tests from time to time. If we put in a little extra work now, it’ll pay off in big dividends later!

Finished product inspections

The final coat has to be put through the wringer and checked out really well. We’re looking for thickness, hardness, flexibility – and can it weather the storm? It needs to meet all those strict specifications with flying colors. So, let’s give it a thorough once-over and make sure we take advantage of every beat!

Capacity and Lead Time Considerations for Scaling Up Production

Making sure the conformal coating manufacturer has enough resources and can hit deadlines is critical when scaling up production. To evaluate a conformal coating material manufacturer’s capacity and lead time, it is advisable to:

Assess their production facilities

Please take a peek into the manufacturer’s production shops to measure up their possibilities. Taking a glance at their mechanisms, processing pathways, and keeping spaces can give you an indication of what they’re capable of. Don’t forget to scope out any extras, too – with the right gear, it could be really something!

Review their production schedule

Do you need the rundown on the producer’s production timeline and lead times? This will clue you into whether they can hit the necessary output quotas by your deadline.

Evaluate their track record

Do your due diligence and check out the manufacturer’s amazing record of punctuality when it comes to getting those orders filled and delivered on time. Dig a little deeper, read the customer reviews, and scan through the case studies – there’s no secret how good this company is at delivering results. See for yourself!

Cost Analysis for Scaling Up Production with a Conformal Coating Material Manufacturer

Cost analysis is an essential piece of the puzzle when it comes to scaling up production with conformal coating material manufacturers. It’s super important that you crunch all the numbers and evaluate whether or not working with this particular manufacturer is feasible financially since it can make or break your budget and money objectives. To get a clear view of the cost-benefit situation, consider these steps:

Evaluate pricing structures

Gathering pricing intel from the maker? That’s just smart – remember to do your homework and check out other vendors, too! When you’re shopping around, look not only at the price tag but all those pesky fine print details like volume discounts, shipping fees, or any extra costs they try to sneak in. Bottom line: Be sure to get the very best deal for your money!

Assess long-term cost savings

Thinking ahead about cost savings is a boon for businesses. After all, teaming up with a conformal coating manufacturer can mean big advantages like cutting material waste and skyrocketing efficiency – not to mention the potential for lower labor costs. It’s worth taking your time to mull it over; after all, you want to take advantage of an opportunity like this!

Consider the total cost of ownership

When considering the cost of coating material, remember to factor in the value of comprehensive technical support, specialized expertise, and quality customer service. Sure, there may be cheaper solutions available upfront – but in the end, you’re better off going with somebody who’ll back you up for the long haul.

Technical Support and Expertise from the Manufacturer

Getting the right kind of technical support and expertise from your coating material manufacturer is key when you’re ramping up production. Fortunately, these manufacturers should provide a broad range of help — every step of the way, from determining which material is best suited to troubleshooting any hiccups that come along.

This could include materials advice like what characteristics and advantages apply to certain products; process optimization guidance including suggestions on specific equipment settings, parameters, etc.; timely assistance if there’s an operational issue; plus, instruction and information around how best to utilize their coatings. That could take shape in the form of classes, webinars, or detailed text docs.

Conclusion and Recommendations for Scaling Up Production with a Conformal Coating Material Manufacturer

Wrapping up, it’s a no-brainer that expanding production and teaming with a conformal coating material manufacturer is an essential phase for electronics producers to keep up with ever-mounting demand and compete in the market. As you decide on one, it’s important to be aware of aspects such as product excellence, the company’s reputation and background, the availability of technical assistance/knowledge, plus consistency with existing production processes and equipment.

For more about the Conformal Coating Material Manufacturer, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.