Innovative Hot Melt Adhesive Manufacturer: Uniting Industries with Expertise

Innovative Hot Melt Adhesive Manufacturer: Uniting Industries with Expertise

Hot melt adhesives are a special type of thermoplastic adhesive that is solid at room temperature but liquefies when heated. These adhesives are designed to be applied in a molten state and then solidify upon cooling to form a strong bond between surfaces.

Hot melt adhesives are composed of a blend of thermoplastic polymers, resins, and additives. They are typically supplied in the form of solid sticks, pellets, or blocks that are loaded into a hot glue gun or a specialized hot melt adhesive application system. When the adhesive is heated, it becomes a viscous liquid with low viscosity, allowing it to be easily applied to surfaces.

Once they are applied, hot melt adhesives quickly begin to cool and solidify, undergoing a phase change from a liquid to a solid state. During this process, they form a strong, durable bond between the substrates they are applied to. The bond is often achieved within seconds to minutes, depending on the adhesive formulation and application conditions.

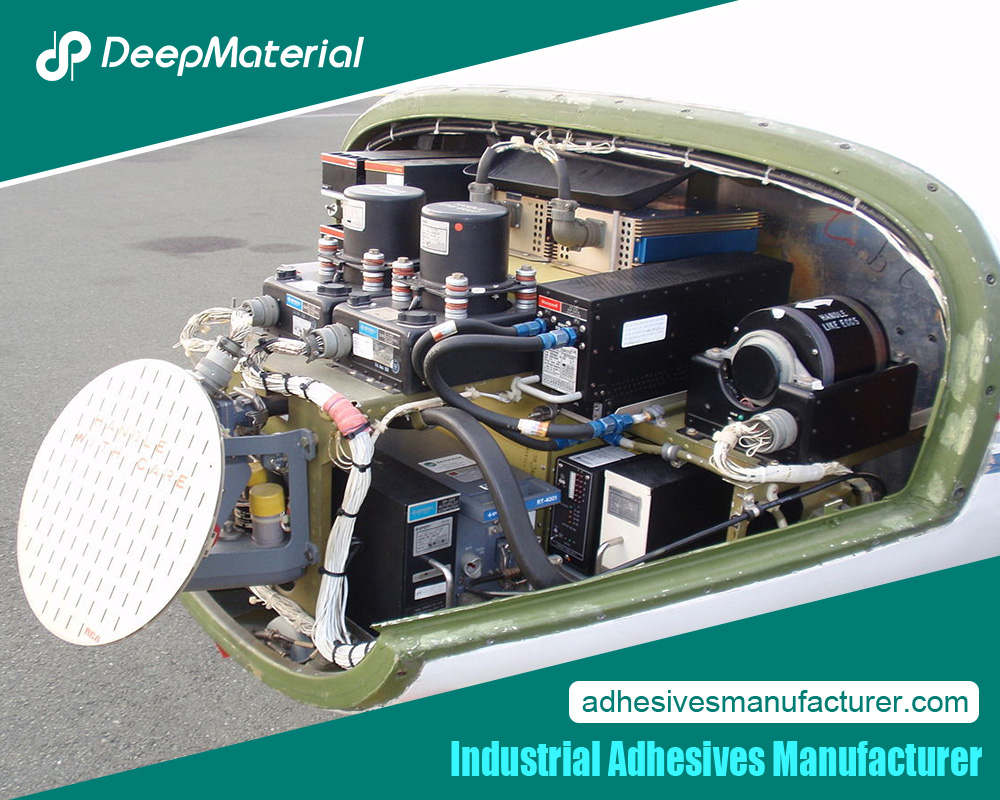

Hot melt adhesives are widely used in various industries and applications due to their fast-bonding capabilities, versatility, and ease of use. They are commonly employed in packaging, woodworking, product assembly, labeling, bookbinding, automotive, and various other manufacturing processes where quick and reliable bonding is required.

Innovative hot melt adhesive manufacturers are taking hot melt adhesive solutions to another level. They have consistently ensured that the emerging solutions are more reliable and environmentally friendly. If you are having trouble discovering a reliable hot melt adhesive manufacturer, then this post is for you.

Hot Melt Adhesives Manufacturers

Hot Melt Adhesives Manufacturers

As stated earlier, hot melt adhesives represent a special class of adhesive solutions. They are quite different from other general adhesives. Hot melt adhesives are made from special formulations. The way they are applied is also slightly different from the way other general adhesives are used.

Manufacturers who produce hot melt adhesives do so because it is their specialty. They have become experts in producing such adhesives over the years. This is why one must be extra vigilant before settling for any hot melt adhesive manufacturer.

Please, do not make the mistake of thinking that all adhesive manufacturers are the same. They are not! While some have all what is necessary for producing hot melt adhesives, some others do not. As we progress in this post, we will see some tips that can guide us in making the right choices when it comes hot melt adhesives manufacturers.

Benefits of Using Hot Melt Adhesives for Industrial Applications

Employing hot melt adhesives in industrial settings provides a multitude of advantages that enhance efficiency, dependability, and cost-efficiency. These merits establish hot melt adhesives as the preferred choice across a broad spectrum of industries. Below, we highlight the primary benefits of utilizing hot melt adhesives in industrial applications.

- Flexibility and Elasticity: Some hot melt adhesive formulations offer flexibility and elasticity, allowing them to accommodate movement, expansion, and contraction of bonded materials. This is important in applications where flexibility is paramount.

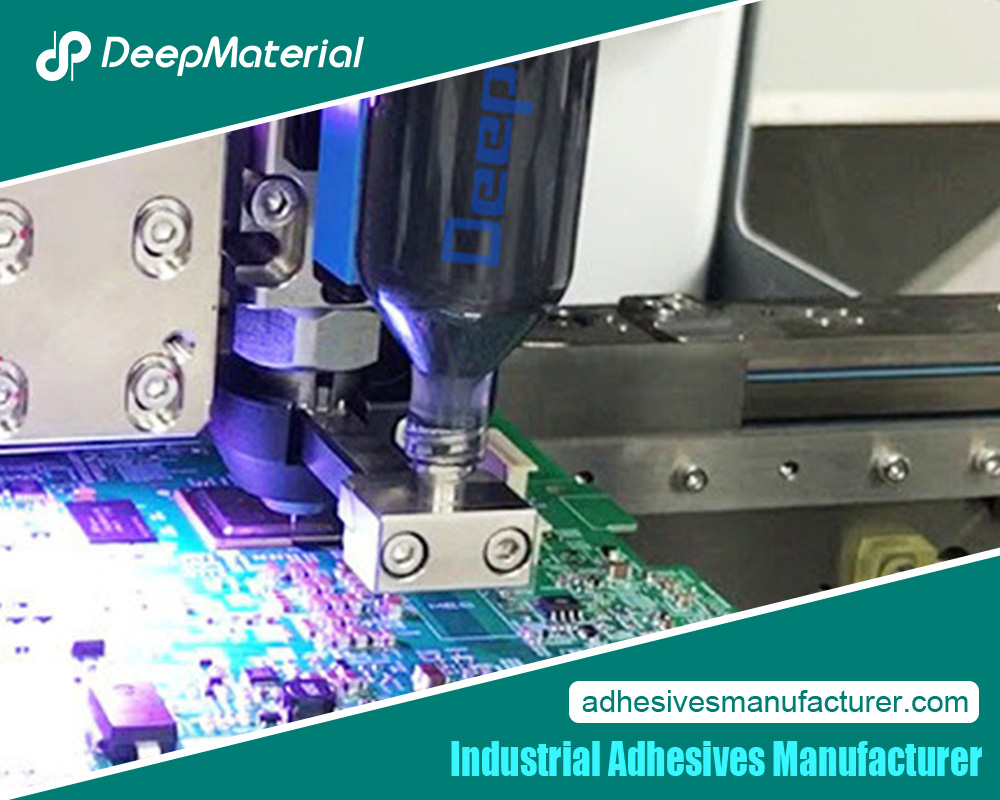

- Ease of Automation: Hot melt adhesive application can be easily automated using adhesive dispensing systems. This reduces labor costs, ensures consistent bonding quality, and enhances production line efficiency.

- Resistance: Hot melt adhesives can be formulated to provide resistance to moisture, chemicals, and environmental factors. This is advantageous in applications exposed to harsh conditions or outdoor environments.

- Minimal Wastage of Materials: Hot melt adhesives are applied precisely, reducing the likelihood of adhesive waste. This efficiency helps minimize material costs and contributes to sustainable manufacturing practices.

- Compatibility: Hot melt adhesives are compatible with a wide range of materials, including plastics, paper, wood, metal, fabric, and more. This versatility allows them to be used in diverse industrial applications.

- Quick Bonding: Hot melt adhesives bond quickly upon application, often within seconds to minutes. This speed enhances production efficiency by reducing assembly or manufacturing cycle times.

- Bond Durability: Hot melt adhesives create strong and durable bonds that withstand various stresses, including impact, vibration, and temperature fluctuations. This reliability ensures the long-term performance of bonded components.

- Does Not Require Any Time for Drying: Unlike other adhesives that require curing or drying time, hot melt adhesives solidify upon cooling. This eliminates the need for extended waiting periods and allows for immediate handling of bonded components.

- Clean Bonds: Hot melt adhesives do not contain solvents or water, resulting in cleaner and environmentally friendly bonding processes. There are no harmful emissions or disposal concerns associated with solvent-based adhesive.

- Better Aesthetics: Hot melt adhesives are frequently employed in applications where visual aesthetics are crucial, such as packaging and labeling, as they can deliver a polished and seamless appearance to bonded surfaces. This enhances the overall visual appeal of products.

- Flexibility: In certain instances, specific hot melt adhesive formulations possess flexibility and elasticity, enabling them to adapt to the movement, expansion, and contraction of bonded materials. This quality is especially valuable in applications demanding flexibility.

- Simple to Handle: Hot melt adhesives are commonly available in solid forms, like sticks or pellets, which are convenient for handling and transportation. This simplifies both storage and application processes.

- Custom Formulations: Manufacturers can develop custom formulations of hot melt adhesives to meet specific industrial requirements, including adhesion strength, open time, and environmental considerations.

The advantages of employing hot melt adhesives in industrial settings include rapid bonding, robust adhesion, versatility across different materials, eco-friendliness, and cost-effectiveness. These merits render hot melt adhesives a versatile and dependable solution for bonding and assembly requirements across various industries.

Final Words

Final Words

Hot melt adhesive manufacturers produce thermoplastic adhesives that solidify upon cooling. They offer rapid bonding, strong adhesion, and compatibility with various materials, making them vital in industries such as packaging, automotive, and woodworking. These manufacturers emphasize innovation, quality, and customization to meet specific industrial needs, contributing to efficiency and cost-effectiveness in diverse applications.

For more about a hot melt adhesive mnufacturer, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.