Industrial Strength Epoxy Adhesive: A Comprehensive Guide

Industrial Strength Epoxy Adhesive: A Comprehensive Guide

Industrial-strength epoxy adhesives have revolutionized various sectors, ranging from aerospace and automotive to construction and electronics. These powerful bonding agents are renowned for their versatility, durability, and ability to withstand extreme conditions, making them indispensable in numerous industrial applications. This article will explore the science behind industrial-strength epoxy adhesives, their critical applications, and their benefits over other bonding solutions.

What is Industrial Strength Epoxy Adhesive?

Epoxy adhesives are a class of polymers formed by the chemical reaction between an epoxide resin and a curing agent, also known as a hardener. Industrial-strength epoxy adhesives are specifically formulated for heavy-duty applications that demand superior strength, resistance to environmental factors, and long-lasting performance. These adhesives are typically two-part systems that, when mixed, initiate a chemical reaction that results in a rigid, thermosetting polymer matrix.

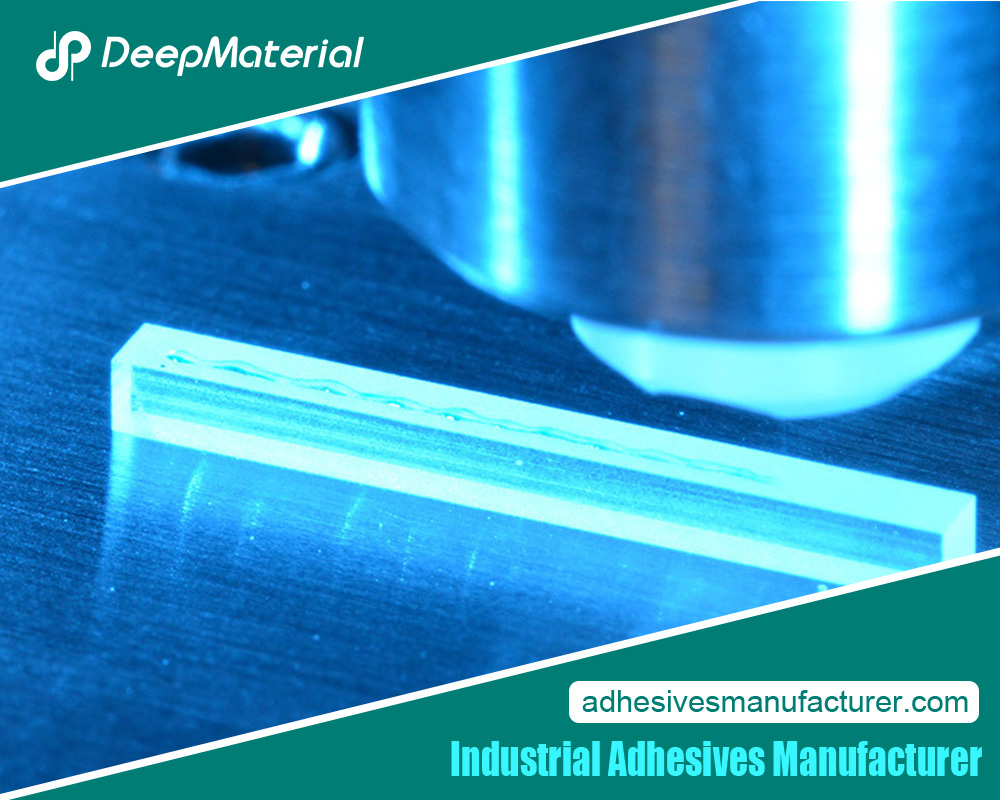

The distinguishing factor of industrial-strength epoxy adhesives is their ability to bond to a wide range of substrates, including metals, ceramics, glass, wood, and plastics. Additionally, they can resist high levels of mechanical stress, heat, chemicals, and moisture, making them ideal for use in challenging environments.

The Science Behind Epoxy Adhesive Bonding

Epoxy adhesives owe their impressive bonding strength to forming chemical solid bonds at the molecular level. The curing process, or crosslinking, occurs when the epoxide groups in the resin react with the curing agent. This creates a tightly interconnected network of molecules, resulting in a rigid and highly durable material.

Several vital properties contribute to the performance of industrial-strength epoxy adhesives:

- Shear and Tensile Strength:Epoxy adhesives are known for their ability to withstand high loads in shear (parallel to the bond line) and tensile (perpendicular to the bond line) applications. This makes them ideal for structural bonding in industries like construction and aerospace.

- Temperature Resistance:Industrial-strength epoxies can withstand extreme temperatures, with some formulations remaining stable at temperatures exceeding 200°C. This property is fundamental in high-heat environments, such as automotive engines and industrial machinery.

- Chemical Resistance:Epoxy adhesives resist various chemicals, including oils, acids, solvents, and fuels. This makes them suitable for use in environments where corrosive substances are exposed daily, such as chemical processing plants.

- Durability and Longevity:Once cured, epoxy adhesives are highly resistant to wear and tear, ensuring long-lasting performance even in harsh conditions. Their durability makes them a cost-effective solution for industries where frequent repairs are undesirable.

Types of Industrial Strength Epoxy Adhesives

Types of Industrial Strength Epoxy Adhesives

Several types of industrial-strength epoxy adhesives are available, each formulated to meet specific bonding requirements. The most common types include:

- One-Part Epoxy Adhesives:These adhesives come pre-mixed and only require heat to activate the curing process. One-part epoxies are easy to use and are often used in automated manufacturing processes. They are ideal for bonding metal components in the automotive and aerospace industries.

- Two-Part Epoxy Adhesives:These adhesives consist of a resin and a hardener that must be mixed before application. Two-part epoxies are versatile and can bond with various materials, including plastics, metals, and composites. They are commonly used in construction and electronics.

- Heat-Resistant Epoxy Adhesives:Formulated to withstand extreme temperatures, these adhesives are used in applications such as automotive engines, industrial furnaces, and aerospace components. They maintain their bond strength even in environments with continuous heat exposure.

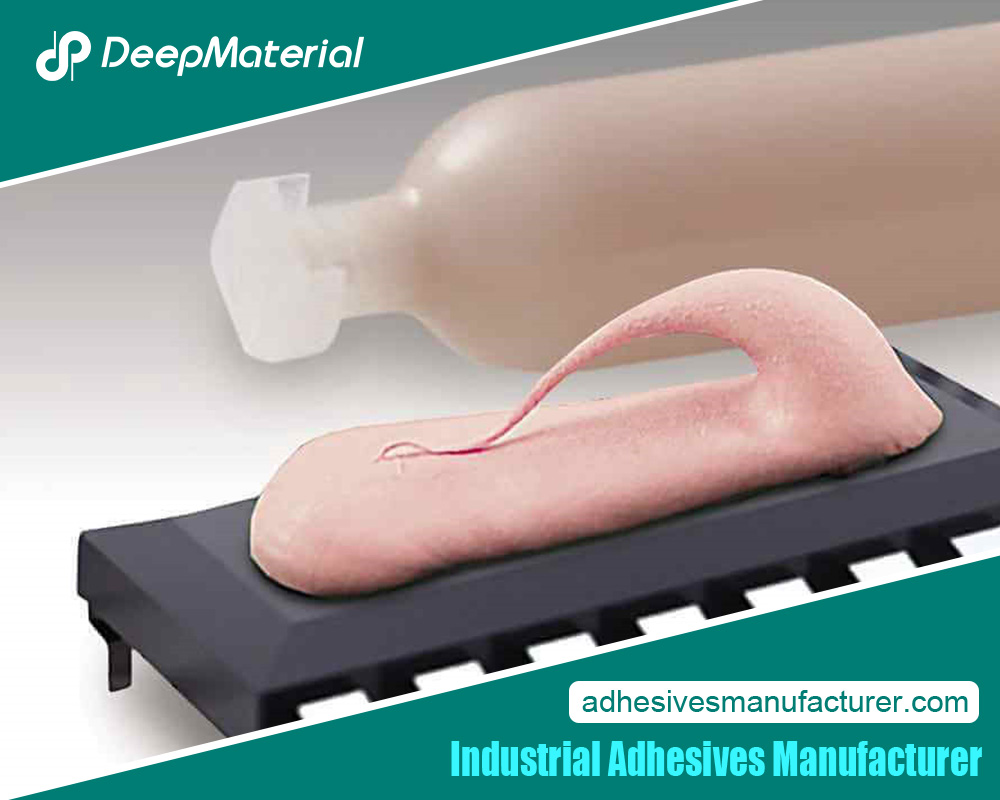

- Flexible Epoxy Adhesives:These epoxies are designed to offer some flexibility after curing, making them suitable for applications where the bonded materials may experience movement or vibration. They are commonly used in the electronics and automotive industries.

- Conductive Epoxy Adhesives:Conductive epoxies contain metallic fillers that allow for electrical conductivity in electronics and electrical applications. They are often used to assemble circuit boards and other electronic components.

Critical Applications of Industrial Strength Epoxy Adhesives

Epoxy adhesives play a crucial role in a variety of industries. Their versatility and durability make them suitable for numerous applications, including:

- Aerospace and Aviation:In the aerospace industry, epoxy adhesives bond composite materials, metals, and other components in aircraft and spacecraft. Their high strength-to-weight ratio makes them ideal for reducing the aircraft’s overall weight without compromising structural integrity. Their resistance to extreme temperatures and chemicals also ensures reliable performance in harsh environments.

- Automotive Industry:Epoxy adhesives are widely used in the automotive sector to bond body panels, reinforce structural components, and seal joints. Their ability to withstand mechanical stress, vibration, and exposure to fuels and oils makes them indispensable in the assembly of modern vehicles. In electric vehicles (EVs), epoxy adhesives bond battery components and other electrical systems.

- Construction and Infrastructure:Industrial-strength epoxy adhesives are commonly used in the construction industry for bonding concrete, steel, and other building materials. They are often employed in applications such as anchoring bolts, repairing cracks in concrete structures, and bonding precast concrete elements. Epoxy adhesives provide excellent load-bearing capacity and resistance to environmental factors, making them ideal for infrastructure projects like bridges and tunnels.

- Electronics and Electrical:Epoxy adhesives are extensively used in the electronics industry to encapsulate and pot components, providing protection from moisture, dust, and mechanical damage. Conductive epoxy adhesives bond electronic components, ensuring electrical conductivity while maintaining a solid bond. Their use in printed circuit board (PCB) assembly and semiconductor packaging is critical to the reliability of modern electronic devices.

- Marine and Offshore:The marine industry relies on epoxy adhesives to resist water, salt, and harsh environmental conditions. They are used in the construction and repair of boats, ships, and offshore platforms, where solid and durable bonds are required to withstand the corrosive effects of seawater. Epoxy adhesives are also used to bond composite materials and construct lightweight, high-performance vessels.

- Renewable Energy:In the renewable energy sector, epoxy adhesives manufacture wind turbine blades and solar panels. Their ability to bond composite materials and withstand exposure to environmental factors such as UV radiation and temperature fluctuations makes them ideal for these applications. Epoxy adhesives play a crucial role in improving the efficiency and longevity of renewable energy systems.

Advantages of Industrial Strength Epoxy Adhesives

Epoxy adhesives offer several advantages over other types of bonding solutions, including:

- Superior Bonding Strength:Epoxy adhesives provide exceptional bonding strength, making them suitable for heavy-duty applications where other adhesives might fail.

- Versatility:Epoxy adhesives can bond various materials, including metals, plastics, composites, ceramics, and glass. This versatility makes them suitable for use in a variety of industries.

- Chemical and Environmental Resistance:Epoxy adhesives are highly resistant to chemicals, moisture, and extreme temperatures, ensuring long-lasting performance in harsh environments.

- Durability:Once cured, epoxy adhesives form a rigid, durable bond that can withstand mechanical stress, vibration, and impact. This durability makes them ideal for structural bonding applications.

- Customizability:Epoxy adhesives can be formulated to meet specific application requirements, such as flexibility, heat resistance, or electrical conductivity. This allows manufacturers to tailor the adhesive properties to suit their needs.

- Cost-Effectiveness:Epoxy adhesives’ durability and longevity make them a cost-effective solution for industrial applications, reducing the need for frequent repairs or replacements.

Limitations of Industrial Strength Epoxy Adhesives

Despite their numerous advantages, industrial-strength epoxy adhesives do have some limitations:

- Curing Time:Epoxy adhesives typically require longer curing times than other adhesives, which may slow manufacturing processes. However, some fast-curing formulations are available for time-sensitive applications.

- Surface Preparation:Proper surface preparation is crucial for achieving a solid bond with epoxy adhesives. This may involve cleaning, sanding, or priming the surfaces to be bonded, adding extra steps to the application process.

- Brittleness:Some epoxy adhesives can become brittle once cured, especially in low-temperature environments. If the adhesive is impacted or moved, this can lead to bond failure. However, flexible epoxy formulations are available to address this issue.

- Temperature Sensitivity:While many epoxy adhesives can withstand high temperatures, some formulations may degrade under continuous exposure to extreme heat. It is essential to choose the correct formulation for the specific temperature range of the application.

Conclusion

Conclusion

Industrial-strength epoxy adhesives are:

- An essential tool in modern manufacturing and construction.

- We are offering unparalleled bonding strength.

- Resistance to environmental factors.

Their versatility makes them suitable for various applications, from aerospace and automotive to electronics and renewable energy. While they have some limitations, advancements in epoxy adhesive technology continue to address these challenges, making them a reliable and cost-effective solution for industrial bonding needs. Whether you are building the next generation of aircraft or assembling high-performance electronics, industrial-strength epoxy adhesives are a vital component of success.

For more about a complete guide to industrial strength epoxy adhesive: a comprehensive guide, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.