Industrial Sealant Manufacturers: An In-depth Guide

Industrial Sealant Manufacturers: An In-depth Guide

Industrial sealants are critical in various industries, providing solutions for bonding, sealing, and protecting materials in multiple applications. From automotive and aerospace to construction and electronics, sealants ensure structural integrity, prevent leaks, and enhance durability. The global market for industrial sealants is driven by the demand for high-performance products capable of withstanding extreme conditions, chemical exposure, and mechanical stresses.

In this article, we will explore the world of industrial sealant manufacturers, their product offerings, industry trends, and key considerations when selecting the proper sealant for your application.

Overview of Industrial Sealants and Their Applications

Industrial sealants are specialized materials designed to bond, seal, and protect surfaces. They are typically used to fill gaps, prevent leaks, and provide protection from environmental factors such as moisture, chemicals, and temperature changes. Unlike adhesives, which primarily bond surfaces together, sealants are designed to maintain flexibility and resist various environmental challenges.

Critical Applications of Industrial Sealants

- Construction: Sealants are used in the construction industry for weatherproofing, sealing joints, and bonding different building materials such as concrete, glass, and metal. They are critical for preventing air and water infiltration in structures, particularly in roofing, windows, and exterior facades.

- Automotive: Sealants are used in the automotive sector to bond and seal various components, such as windshields, headlights, and engine parts. They help improve vehicle safety, enhance durability, and reduce noise and vibration.

- Aerospace applications demand high-performance sealants that withstand extreme temperatures, pressures, and chemical exposures. Sealants in this sector are used for sealing fuel tanks, windows, and other critical components.

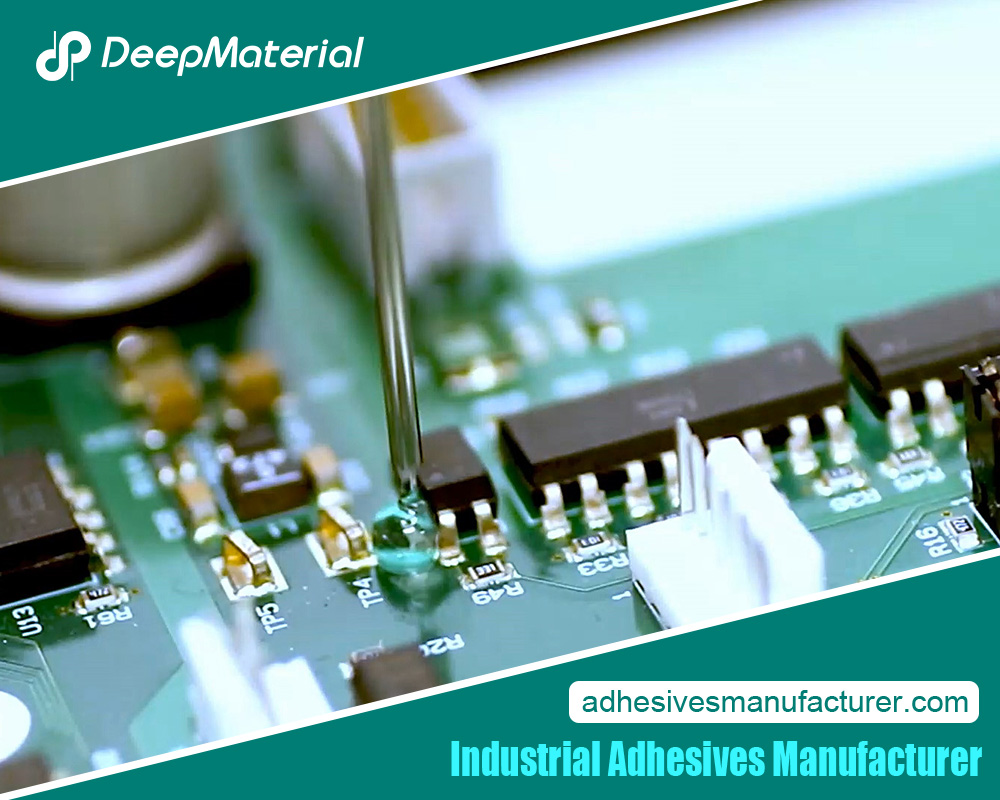

- Electronics: In electronics manufacturing, sealants protect sensitive components from moisture, dust, and other environmental factors. They are essential for encapsulating and protecting circuit boards and connectors.

- Marine: Marine sealants protect against water and corrosion in shipbuilding and repair. They are crucial for sealing hulls, decks, and other marine structures.

Types of Industrial Sealants

Industrial sealants come in various formulations to meet the specific needs of different industries. Some of the most common types of sealants include:

Silicone Sealants

Silicone-based sealants are known for their flexibility, temperature resistance, and excellent weatherproofing capabilities. They are widely used in construction, automotive, and aerospace industries. Silicone sealants maintain their properties over a wide temperature range and are resistant to UV rays, making them ideal for outdoor applications.

Polyurethane Sealants

Polyurethane sealants offer a good balance of flexibility, adhesion, and durability. They are commonly used in construction to seal joints and gaps and in automotive applications to bond and seal body panels. Polyurethane sealants resist chemicals, abrasion, and environmental exposure, making them suitable for demanding applications.

Acrylic Sealants

Acrylic sealants are water-based and easy to apply, making them popular in general-purpose applications such as sealing windows, doors, and building gaps. They are paintable and offer good adhesion to a wide range of surfaces. However, acrylic sealants may not perform well in extreme temperatures or applications requiring high flexibility.

Butyl Sealants

Butyl sealants are highly elastic and provide excellent adhesion to various substrates, including glass, metal, and plastic. They are commonly used in the automotive and construction industries for sealing and bonding. They are ideal for applications that require long-term flexibility and moisture resistance.

Epoxy Sealants

Epoxy-based sealants provide excellent bonding strength and chemical resistance. They are often used in industrial applications where strong adhesion and resistance to harsh environments are required. Epoxy sealants are commonly used in aerospace, electronics, and marine industries.

Top Industrial Sealant Manufacturers

Top Industrial Sealant Manufacturers

The global market for industrial sealants is dominated by a few critical players known for their innovation, quality, and wide range of product offerings. These manufacturers cater to various industries, providing customized application sealant solutions. Below are some of the top industrial sealant manufacturers:

3M

3M is a global leader in adhesives, sealants, and other industrial solutions. Their product portfolio includes a wide range of industrial sealants for automotive, aerospace, construction, and electronics applications. 3 M’s sealants are known for their durability, flexibility, and resistance to environmental factors. Popular products include silicone and polyurethane-based sealants for demanding industrial applications.

Henkel

Henkel is another leading manufacturer of industrial sealants, offering a wide range of products under its Loctite brand. Henkel’sIts sealants are used in the automotive, electronics, aerospace, and general manufacturing industries. Its innovative products, such as the Loctite line of silicone and epoxy sealants, are designed for high-performance bonding and sealing applications. Henkel is known for its focus on sustainability and for offering environmentally friendly solutions.

Sika AG

Sika AG is a Swiss multinational company specializing in chemical products for construction and industry. Its industrial sealants are widely used in the building, automotive, and aerospace sectors. The company’s product range includes polyurethane and silicone-based sealants known for their high adhesion and flexibility. Sika’s sealants are designed to provide long-lasting protection against environmental factors, including moisture, UV rays, and chemicals.

Dow

Dow is a global leader in silicones and specialty chemicals, offering a wide range of sealants for industrial applications. Dow’s sealants are used in the construction, automotive, electronics, and energy industries. Their silicone-based sealants are known for their excellent weatherproofing capabilities, making them ideal for outdoor and extreme environments. Dow’s commitment to innovation and sustainability has made it a top choice for industrial sealant solutions.

Bostik

Bostik, a subsidiary of Arkema, is a leading manufacturer of adhesives and sealants for industrial and consumer markets. Its sealants are used in the construction, automotive, aerospace, and packaging industries. Bostik’s product range includes polyurethane, silicone, and hybrid sealants designed for high-performance sealing and bonding applications. Bostik’s focus on innovation has led to developing advanced sealant technologies that meet the evolving needs of industrial applications.

Master Bond

Master Bond is a leading manufacturer of epoxy-based sealants and adhesives for industrial applications. Their products are widely used in the aerospace, electronics, and medical industries. Master Bond’s epoxy sealants are known for their strong adhesion, chemical resistance, and high-temperature stability. The company offers customized solutions for demanding environments, making it a top choice for specialized industrial applications.

Key Considerations When Choosing an Industrial Sealant Manufacturer

Selecting the proper industrial sealant manufacturer is crucial for ensuring the success of your application. Here are some key factors to consider when choosing a sealant manufacturer:

Industry Expertise

Different industries have unique requirements for sealants, whether it’s temperature resistance in aerospace or chemical resistance in electronics. Choose a manufacturer with a proven track record in your industry, as they will understand the specific challenges and provide tailored solutions.

Product Range

A wide product range is essential for finding the proper sealant for your specific application. Leading manufacturers offer various sealant types, including silicone, polyurethane, epoxy, and hybrid sealants, to meet different needs. Ensure the manufacturer provides diverse products that align with your requirements.

Quality and Certification

Quality is a critical factor when selecting an industrial sealant manufacturer. Look for manufacturers with ISO certifications and adherence to industry standards, as this ensures that their products meet rigorous quality requirements. In industries such as aerospace and medical, compliance with specific standards such as AS9100 or FDA regulations is essential.

Customization and Support

Industrial applications often require customized sealant solutions. Leading manufacturers offer technical support and customization services to meet your project’s unique needs. Look for manufacturers who can provide expert advice, technical data, and on-site support to ensure your application’s success.

Sustainability and Environmental Impact

Sustainability is becoming increasingly important in industrial applications. Many manufacturers are developing eco-friendly sealants that reduce VOC (volatile organic compound) emissions and offer long-lasting performance. Choose a manufacturer committed to sustainability and environmental responsibility.

Industry Trends in Industrial Sealants

The industrial sealant market constantly evolves, with new trends and technologies shaping the industry’s future. Some of the key trends include:

- Sustainability: Manufacturers focus on developing environmentally friendly sealants with low VOC emissions and recyclable packaging. Sustainable sealants reduce the environmental impact and meet stringent regulatory requirements.

- Hybrid Sealants: Hybrid sealants, which combine the properties of different sealant types (such as silicone and polyurethane), are gaining popularity due to their enhanced performance. These sealants offer superior adhesion, flexibility, and resistance to environmental factors.

- Innovative Sealants: Innovations in intelligent materials are leading to the development of sealants that can self-heal, change properties based on ecological conditions, or provide real-time performance monitoring. These advanced materials are being researched for use in critical applications such as aerospace and construction.

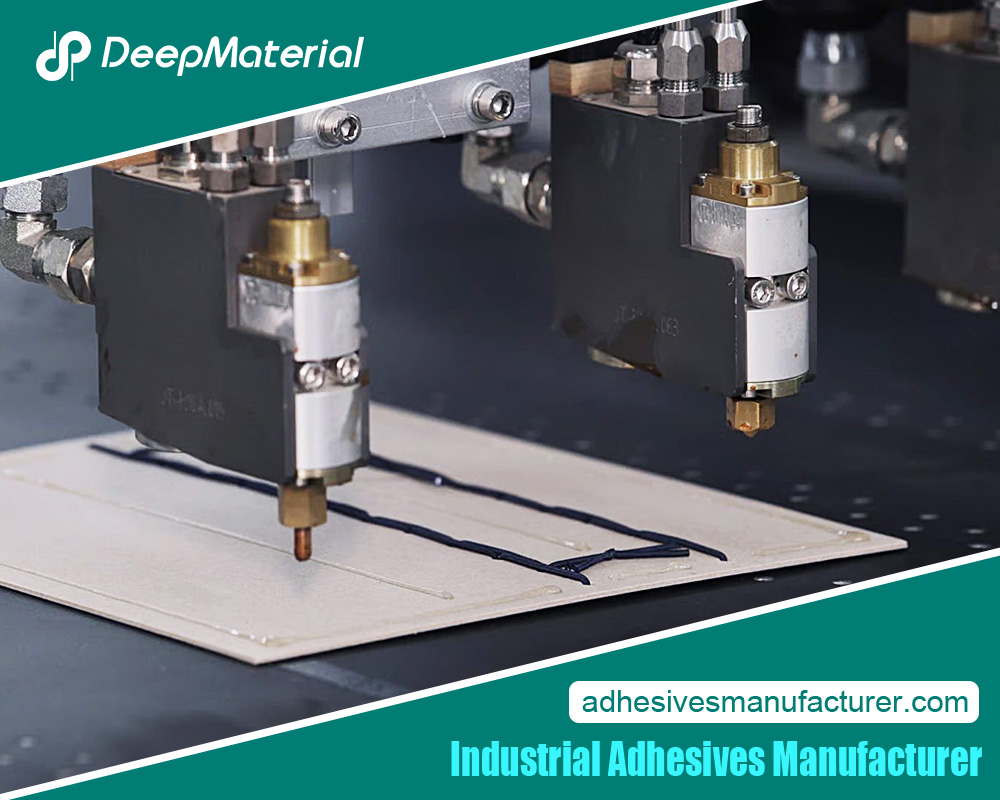

- Automation and Robotics: The rise of automation and robotics in manufacturing drives the demand for sealants that can be easily applied using robotic systems. Manufacturers are developing sealants with optimized flow properties for automated dispensing.

Conclusion

Industrial sealants are vital to modern manufacturing, construction, and engineering industries. As the demand for high-performance sealants continues to grow, manufacturers are developing innovative solutions to meet the evolving needs of various sectors. By understanding the different types of sealants, key industry players, and emerging trends, you can make informed decisions when selecting the proper sealant for your application.

Choosing a reliable industrial sealant manufacturer is critical to ensuring the success and longevity of your projects. When selecting a manufacturer, consider factors such as product range, industry expertise, quality certifications, and sustainability. By partnering with the proper manufacturer, you can achieve optimal results and enhance your products’ and structures’ performance and durability.

For more about a complete guide to industrial sealant manufacturers: an in-depth guide, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.