Industrial Polyurethane Adhesives Supplier: A Comprehensive Overview

Industrial Polyurethane Adhesives Supplier: A Comprehensive Overview

Polyurethane adhesives are critical in various industries due to their versatile bonding properties, durability, and flexibility. Industries such as automotive, construction, electronics, and packaging rely on polyurethane adhesives to bond diverse materials such as metals, plastics, wood, glass, and fabrics. Finding a reliable industrial polyurethane adhesives supplier is essential for companies that want to maintain high-quality production standards and enhance the longevity of their products.

This article will explore what makes polyurethane adhesives unique, the industries that benefit from them, key factors in choosing a supplier, and why polyurethane adhesive technology is becoming more critical in modern manufacturing.

What Are Polyurethane Adhesives?

Polyurethane (PU) adhesives are polymers formed by the reaction of polyols and diisocyanates, two essential chemical compounds. These adhesives are valued for bonding with many substrates, including those traditionally challenging to bond with other adhesives. Polyurethane adhesives can be classified into types based on their curing mechanisms, including one-component (1K) and two-component (2K) systems.

- One-component polyurethane adhesives (1K)cure when exposed to moisture from the atmosphere or substrates. Due to their ease of application, they are often used in the construction and automotive industries.

- Two-component polyurethane adhesives (2K)require mixing two parts, usually a resin and a hardener. These adhesives offer faster curing times and higher strength, which is ideal for demanding industrial applications.

Polyurethane adhesives are known for their outstanding adhesion strength, flexibility, and resistance to chemicals and environmental conditions, making them a preferred choice for various industrial applications.

Industries Benefiting from Polyurethane Adhesives

Industries Benefiting from Polyurethane Adhesives

Automotive Industry

The automotive industry heavily relies on polyurethane adhesives for their high strength, flexibility, and durability. These adhesives bond vehicle parts such as panels, windows, and interior components. Polyurethane adhesives can withstand the harsh conditions that vehicles are exposed to, including temperature fluctuations, moisture, and vibrations. Their ability to bond dissimilar materials like plastics to metal without compromising performance makes them indispensable in automotive manufacturing.

Polyurethane adhesives also contribute to vehicle weight reduction, as they allow for the use of lightweight composite materials in place of traditional heavy metals. This helps manufacturers meet fuel efficiency standards while maintaining the vehicle’s structural integrity.

Construction Industry

In construction, polyurethane adhesives bond a wide range of materials, such as wood, concrete, glass, and insulation materials. Their weather-resistant properties are ideal for exterior applications like roofing, windows, and doors. These adhesives are also valued for maintaining solid bonds in dry and wet conditions, making them suitable for outdoor applications where moisture and temperature variations are prevalent.

Additionally, polyurethane adhesives are often used in green building materials, helping companies meet sustainability goals by providing strong, durable bonds without mechanical fasteners, which can introduce thermal bridging and increase energy loss.

Electronics Industry

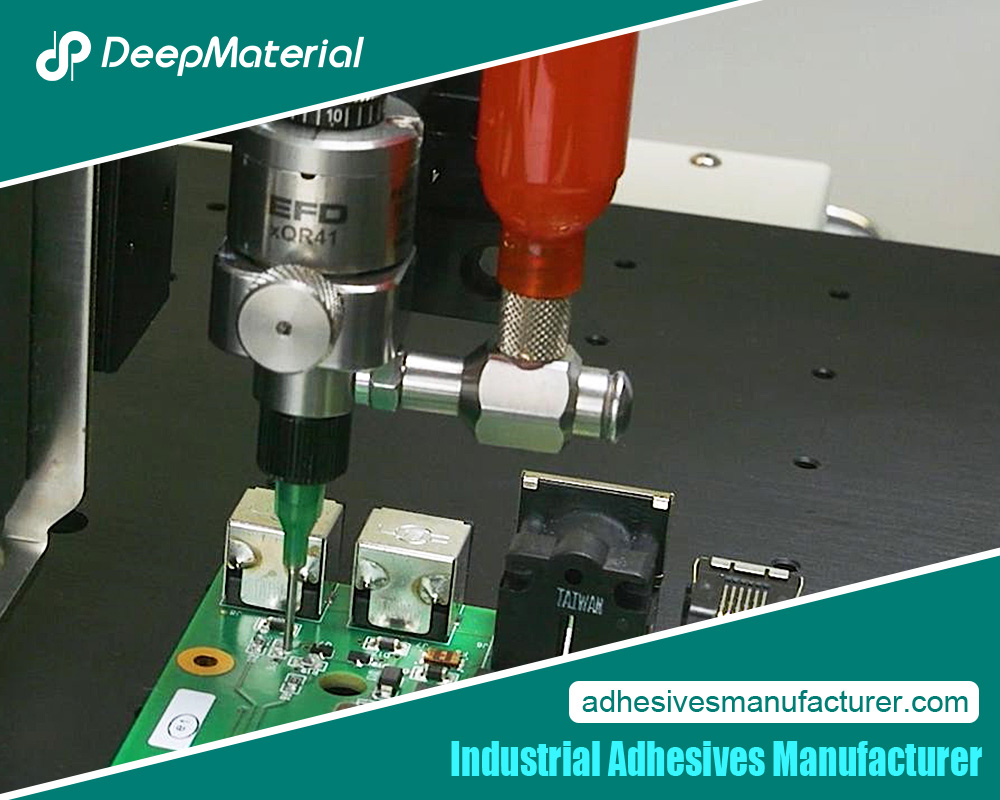

The electronics industry uses polyurethane adhesives to encapsulate components, potting, and coating. These adhesives provide excellent electrical insulation and protect sensitive electronic components from moisture, dust, and vibrations. Their versatility allows them to be used in everything from smartphones and tablets to industrial machinery, where long-term performance and protection are crucial.

In addition, polyurethane adhesives’ heat resistance and flexibility are advantageous in the rapidly evolving electronics industry, where devices are becoming smaller and more complex. Their non-conductive properties also make them safe for electrical circuits, providing manufacturers with a reliable bonding solution.

Packaging Industry

Polyurethane adhesives are commonly used in the packaging industry, particularly for flexible packaging solutions. Their excellent adhesion properties ensure that packaging materials such as films, foils, and laminates bond securely. Polyurethane adhesives contribute to the structural integrity of packaging, making it resistant to tears and punctures, which is vital in protecting the contents.

Moreover, the food packaging industry benefits from polyurethane adhesives that meet stringent food safety standards. These adhesives are used in producing packaging that maintains its bond integrity under varying temperature and humidity conditions, keeping food products safe and secure during transport and storage.

Critical Factors in Choosing a Polyurethane Adhesives Supplier

Selecting a reliable polyurethane adhesive supplier is critical to ensuring the quality and performance of your final product. Several key factors should be considered when choosing an industrial polyurethane adhesive supplier.

Product Quality and Range

One of the first considerations is the range and quality of products the supplier offers. A good supplier should provide various polyurethane adhesives tailored to different industrial needs, whether high-strength bonding, flexibility, or resistance to harsh environmental conditions.

Manufacturers should seek suppliers with a proven track record of delivering consistent, high-quality products that meet industry standards. Look for certifications like ISO 9001, demonstrating a supplier’s commitment to maintaining quality management systems.

Customization Capabilities

Industries often have unique requirements for their bonding solutions. A supplier that offers customization services can create tailor-made polyurethane adhesives that meet specific performance criteria. Whether you need an adhesive with faster curing times, higher temperature resistance, or specific viscosity levels, a supplier with R&D capabilities can meet your needs.

Custom formulations can lead to better product performance, cost savings, and greater efficiency in production processes.

Technical Support and Expertise

Polyurethane adhesives require precise application methods to achieve optimal results. Therefore, partnering with a supplier that provides strong technical support is essential. This includes guidance on proper adhesive selection, application techniques, and troubleshooting potential issues during production.

A knowledgeable supplier can help ensure that you’re using the most effective adhesive for your specific application. This can prevent costly errors and improve production efficiency. Many suppliers also offer on-site training for your staff to ensure that adhesives are applied correctly.

Supply Chain Reliability

Consistent supply and timely delivery are essential in keeping your production line running smoothly. A supplier with a strong global presence and robust supply chain management can help mitigate risks such as delays, stock shortages, and fluctuating raw material costs. Choose a supplier with a reputation for timely deliveries and a well-organised logistics network to avoid disruptions in your production process.

Sustainability Initiatives

As environmental regulations become stricter, industries increasingly seek adhesive solutions that align with their sustainability goals. Many polyurethane adhesives suppliers now offer eco-friendly options that reduce the use of volatile organic compounds (VOCs) and adhere to environmental standards.

Choosing a sustainable supplier can help you meet regulatory requirements and contribute to corporate social responsibility initiatives. Look for suppliers who offer low-VOC adhesives or products certified as environmentally friendly.

Why Polyurethane Adhesive Technology Is on the Rise

Polyurethane adhesives are becoming more essential in modern manufacturing for several reasons. Their flexibility, durability, and adaptability to different substrates allow manufacturers to innovate and develop more advanced products. Moreover, with the global push for lightweight materials, especially in industries like automotive and aerospace, polyurethane adhesives offer the perfect solution by enabling the bonding of composite materials without sacrificing strength.

Another reason for the rise of polyurethane adhesive technology is the growing demand for eco-friendly and sustainable solutions. Many polyurethane adhesives are formulated to meet environmental standards, reducing harmful emissions during application. This is critical as industries worldwide are pressured to meet strict environmental regulations.

The rapid pace of industrial development also drives the demand for adhesives that can handle more complex and demanding applications. Polyurethane adhesives’ ability to resist chemical, environmental, and physical stresses makes them a go-to solution for manufacturers seeking reliability in their production processes.

Conclusion

Conclusion

Due to their flexibility, strength, and resistance to various environmental factors, polyurethane adhesives are indispensable in the automotive, construction, electronics, and packaging industries. Choosing the right industrial polyurethane adhesives supplier involves considering product quality, customization options, technical support, and supply chain reliability. As industries continue to innovate and emphasise sustainability, the demand for polyurethane adhesives will continue to rise.

A reliable supplier provides high-quality adhesives and partners with manufacturers to meet their evolving needs. Whether it’s ensuring a vehicle’s structural integrity or protecting sensitive electronics, polyurethane adhesives are playing an increasingly important role in modern industry, and the right supplier can be vital to staying competitive in the marketplace.

For more about a complete guide to industrial polyurethane adhesives supplier: a comprehensive overview, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.