Industrial Epoxy Adhesive Suppliers: Tips for Building Strong Supplier Relationships

Industrial Epoxy Adhesive Suppliers: Tips for Building Strong Supplier Relationships

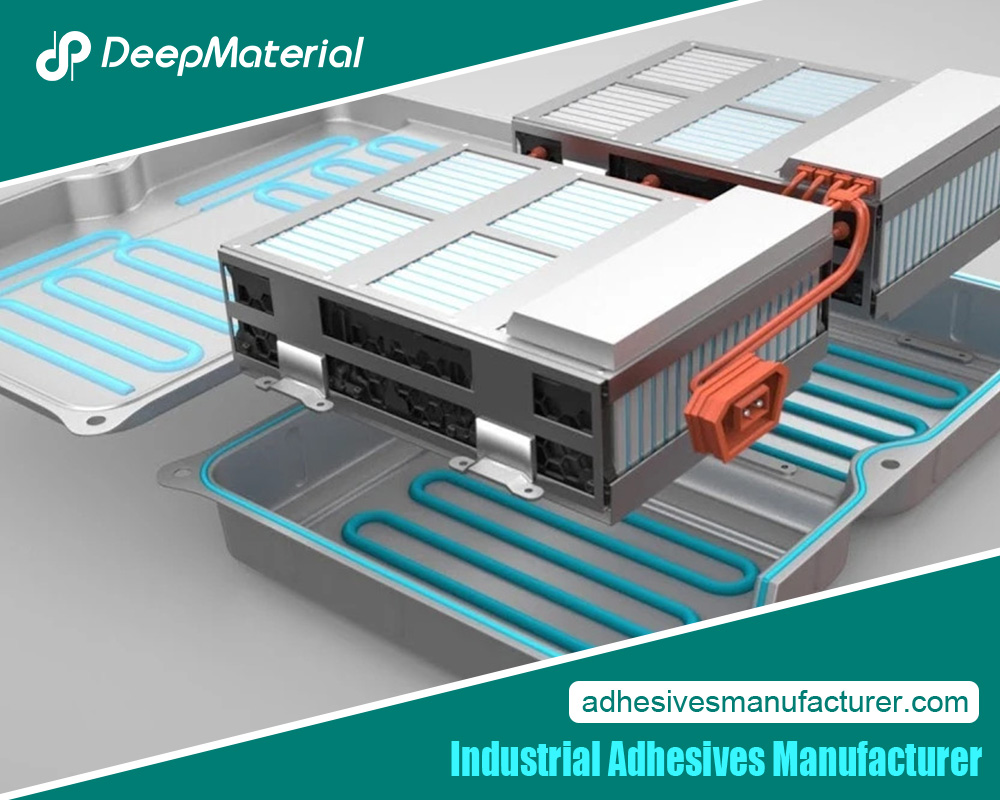

In the dynamic world of industrial manufacturing, the importance of building and maintaining strong relationships with suppliers cannot be overstated. This is particularly true when it comes to sourcing essential materials like industrial epoxy adhesives, which play a pivotal role in a wide range of applications. As a key component in everything from automotive assembly to aerospace engineering, the quality, reliability, and performance of these adhesives can significantly impact the final product’s integrity.

In this blog post, we will delve into the world of industrial epoxy adhesive suppliers, providing valuable insights and practical tips to help you build strong, mutually beneficial relationships with these crucial partners.

Understanding Your Industrial Epoxy Adhesive Needs

Before choosing an industrial epoxy adhesive supplier, it is important to understand your specific adhesive needs. This includes identifying the type of adhesive required, the specific application, and any special requirements or specifications. By understanding your needs, you can choose a supplier that can meet your requirements effectively.

When choosing an industrial epoxy adhesive supplier, there are several factors to consider. These include the supplier’s experience and expertise in the industry, their product range and capabilities, their quality control processes, and their ability to meet your specific requirements. It is important to choose a supplier that has a track record of delivering high-quality products and has the necessary certifications and accreditations.

Researching Potential Suppliers

When researching potential industrial epoxy adhesive suppliers, there are several sources of information that can be helpful. These include industry trade shows, online directories, industry publications, and referrals from other businesses in the industry. It is important to gather as much information as possible about potential suppliers to make an informed decision.

When evaluating potential suppliers, there are several criteria to consider. These include the supplier’s reputation and track record, their financial stability, their production capacity and capabilities, their quality control processes, and their ability to meet your specific requirements. It is important to choose a supplier that has a proven track record of delivering high-quality products and has a reputation for reliability and customer satisfaction.

Evaluating Supplier Capabilities and Quality

When evaluating supplier capabilities and quality, there are several factors to consider. These include the supplier’s production capacity, their quality control processes, their certifications and accreditations, and their responsiveness and flexibility. It is important to choose a supplier that has the necessary resources and capabilities to meet your specific requirements.

Supplier certifications and quality control processes are important indicators of a supplier’s commitment to quality. It is important to choose a supplier that has the necessary certifications and accreditations to ensure that their products meet the required standards. Additionally, it is important to assess the supplier’s quality control processes to ensure that they have effective measures in place to maintain consistent product quality.

Negotiating Favorable Terms and Pricing

Negotiating favorable terms and pricing with industrial epoxy adhesive suppliers is an important aspect of building strong supplier relationships. It is important to understand the supplier’s cost structure and profit margins to negotiate fair pricing. Additionally, it is important to balance cost with quality and reliability to ensure that you are getting the best value for your money.

When negotiating terms and pricing, it is important to have a clear understanding of your requirements and expectations. This includes the quantity of adhesive required, the delivery schedule, and any special requirements or specifications. By clearly communicating your needs, you can negotiate terms and pricing that are favorable for both parties.

Establishing Clear Communication Channels

Establishing clear and open communication channels with industrial epoxy adhesive suppliers is crucial for building strong relationships. It is important to establish communication protocols and expectations to ensure that both parties are on the same page. Additionally, it is important to address any language or cultural barriers that may exist.

Clear and open communication is essential for a successful partnership with industrial epoxy adhesive suppliers. It is important to establish regular communication channels, such as phone calls, emails, or meetings, to discuss any issues or concerns. By maintaining regular communication, you can address any issues or changes in a timely manner.

Maintaining Consistent Orders and Timelines

This is crucial for building strong supplier relationships. By placing consistent orders and adhering to agreed-upon timelines, businesses can demonstrate their reliability and commitment to the supplier. This can help build trust and strengthen the partnership.

Consistency in orders is important for suppliers to plan their production schedules and manage their inventory effectively. By placing consistent orders, businesses can help suppliers optimize their production processes and reduce costs. Additionally, consistent orders can help suppliers plan their resources and ensure that they have the necessary materials and capacity to meet the demand.

Addressing Issues and Resolving Disputes

It is important to address any issues or concerns as soon as they arise and work together with the supplier to find a solution. By maintaining a positive and respectful relationship, businesses can resolve conflicts and strengthen the partnership.

Addressing issues and disputes in a timely manner is important to prevent them from escalating and causing further damage to the relationship. It is important to communicate any issues or concerns to the supplier as soon as they arise and work together to find a solution. By addressing issues promptly, businesses can prevent them from impacting production schedules or causing delays.

Cultivating Long-Term Partnerships with Industrial Epoxy Adhesive Suppliers

This can bring numerous benefits to businesses. Long-term partnerships can lead to improved product quality, better pricing, faster delivery times, and access to new technologies and innovations. By investing in supplier relationships, businesses can gain a competitive edge in the market.

One of the benefits of long-term partnerships with industrial epoxy adhesive suppliers is improved product quality. When businesses have a long-term relationship with a supplier, they can work together to improve product quality and meet the specific requirements of the business. This can lead to better products and increased customer satisfaction.

Conclusion

Building strong supplier relationships with industrial epoxy adhesive suppliers is crucial for the success of businesses. By investing in supplier relationships, businesses can gain numerous benefits, including improved product quality, better pricing, faster delivery times, and access to new technologies and innovations. To build strong supplier relationships, businesses should understand their specific adhesive needs, research potential suppliers, evaluate supplier capabilities and quality, negotiate favorable terms and pricing, establish clear communication channels, maintain consistent orders and timelines, address issues and resolve disputes, and cultivate long-term partnerships.

For more about a complete guide to industrial adhesive manufacturers and their products,you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.