Industrial Automotive Adhesive Manufacturers: A Comprehensive Overview

Industrial Automotive Adhesive Manufacturers: A Comprehensive Overview

The automotive industry has long relied on high-quality adhesives to enhance vehicle design, durability, and performance. These adhesives play a critical role in modern vehicle assembly by bonding various materials like metals, plastics, composites, and glass, ultimately making vehicles lighter, safer, and more efficient. The demand for automotive adhesives has led to the rise of specialized manufacturers dedicated to creating adhesives tailored to the industry’s rigorous standards. This article delves into the significance, types, applications, and leading manufacturers of industrial automotive adhesives.

Importance of Adhesives in the Automotive Industry

Automotive adhesives are indispensable for vehicle manufacturing as they offer several advantages over traditional mechanical fasteners, such as bolts and welds. Here are some of the primary reasons why adhesives are preferred in automotive applications:

- Weight Reduction: Reducing vehicle weight is a top priority in the automotive sector to improve fuel efficiency and reduce emissions. Adhesives enable manufacturers to join different materials with minimal added weight compared to traditional fastening methods.

- Enhanced Durability and Strength: Industrial adhesives distribute stress evenly across bonded surfaces, reducing the likelihood of joint failure and improving overall durability. This feature is especially crucial in parts that experience significant vibrations, such as the engine and suspension.

- Improved Safety: Adhesives contribute to vehicle crashworthiness by absorbing and distributing impact forces more effectively than mechanical fasteners. This capability is critical in constructing the passenger cabin, where safety is paramount.

- Design Flexibility: Adhesives allow for greater design flexibility, as they can bond dissimilar materials without drilling holes or other modifications. This flexibility is essential as automotive manufacturers experiment with innovative materials and designs to enhance performance and aesthetics.

- Cost Efficiency: Adhesive bonding can streamline the assembly process, reducing labor and production costs. Since adhesives cure quickly, they also enable faster production rates, helping manufacturers meet tight deadlines.

Types of Automotive Adhesives

The automotive industry relies on various types of adhesives, each with distinct properties suited to specific applications. Here are some of the most common types:

- Epoxy Adhesivesare commonly used in structural bonding applications. They are known for their high strength and durability and offer excellent resistance to heat, chemicals, and environmental factors, making them suitable for bonding metal components in chassis and body structures.

- Acrylic Adhesives: Acrylic adhesives provide fast curing times and high impact resistance, making them ideal for applications that require flexibility and strength. They are widely used for bonding plastic and composite materials and are highly resistant to environmental conditions.

- Polyurethane Adhesives: Polyurethane adhesives are versatile and provide strong, flexible bonds. They are often used in applications that require vibration damping, such as interior components and vehicle dashboards. They also have good resistance to moisture and temperature fluctuations.

- Silicone Adhesives: Silicone adhesives are ideal for applications that require high temperature and environmental resistance. They are used for sealing and gasketing in engines and other high-temperature areas and bonding glass and mirrors.

- Hot Melt Adhesives: Known for their fast-setting times, hot melt adhesives are used in non-structural applications such as interior trim bonding. They offer excellent adhesion to various surfaces and are widely used in areas that do not experience extreme stress.

- Pressure-sensitive adhesives (PSAs): PSAs are commonly used to attach automotive trims, badges, and emblems. They provide initial solid adhesion and do not require curing, making them suitable for non-structural applications.

Applications of Automotive Adhesives

The versatility of adhesives makes them suitable for various applications across different vehicle parts. Here are some of the primary applications in which automotive adhesives play a crucial role:

- Body Assembly: Adhesives are widely used in body assemblies to bond structural components and resist crashes in modern vehicles. In some areas, they replace spot welding, offering a cleaner and more efficient joining method that reduces the risk of corrosion.

- Powertrain Assembly: Adhesives are used in powertrain components, such as engines and transmissions, to withstand high temperatures and vibrations. Engine gaskets, oil pans, and cylinder heads are often bonded with high-performance adhesives to ensure leak-free and durable seals.

- Interior Assembly: Automotive adhesives are essential in bonding interior components, including dashboards, door panels, and trim. They offer excellent adhesion to materials like plastics, leather, and fabric, contributing to the vehicle’s aesthetics and comfort.

- Windshield Bonding: Windshield adhesives provide a robust, watertight seal between the glass and vehicle frame. These adhesives play a significant role in maintaining structural integrity and occupant safety during a collision.

- Electrical and Electronic Components: Adhesives are also used to bond and protect electronic components, such as circuit boards and sensors. These adhesives ensure proper insulation and resistance to moisture, vibration, and temperature changes.

- Lightweight Applications: With the growing emphasis on lightweight materials, adhesives are essential in bonding aluminum, magnesium, and composite materials. Adhesives help reduce vehicle weight without compromising strength, enhancing fuel efficiency and performance.

Key Automotive Adhesive Manufacturers

The demand for advanced automotive adhesives has led to the growth of numerous manufacturers specializing in high-performance bonding solutions. Below are some of the leading industrial automotive adhesive manufacturers:

Henkel AG & Co. KGaA

Henkel is one of the largest global suppliers of adhesive solutions for the automotive industry. The company offers various adhesives, sealants, and functional coatings under its LOCTITE and TEROSON brands. Henkel’s adhesives are used in applications from body assembly to powertrain and electronic bonding, with a strong focus on sustainability and lightweight.

3M Company

3M is known for its innovative adhesive technologies that support lightweight, noise reduction, and structural integrity in automotive applications. The company’s product range includes structural adhesives, pressure-sensitive tapes, and sealants, all designed to improve efficiency and safety in automotive manufacturing. 3 M’s VHB (Very High Bond) tapes are particularly popular in the automotive industry for exterior trim and badge bonding.

Sika AG

Sika is a global leader in providing adhesives and sealants for the automotive sector. Its products, mainly structural bonding, are used extensively in body shop and assembly applications. Sika’s expertise lies in formulating adhesives that meet specific OEM requirements for durability, crash resistance, and environmental impact.

H.B. Fuller

H.B. Fuller is a critical player in the automotive adhesives market, offering high-performance products for various applications, from interior trims to structural components. The company’s focus on sustainability and innovation has led to the development of adhesives that improve vehicle strength while reducing weight.

Bostik (Arkema Group)

Bostik, part of the Arkema Group, provides advanced bonding solutions for automotive interiors, exteriors, and body-in-white applications. Known for its high-performance structural adhesives, Bostik’s solutions offer excellent resistance to vibration and thermal cycling, making them ideal for vehicle assembly.

Dow Inc.

Dow offers a wide range of silicone-based adhesives and sealants designed for durability in extreme environments. Dow’s adhesives are used in applications that require resistance to high temperatures, moisture, and chemicals. Its Betaseal series is commonly used to bond vehicle windshields and other glass components.

Ashland Global Holdings Inc.

Ashland provides specialty adhesives for automotive applications, focusing on high-strength and environmentally friendly formulations. The company’s products are widely used in interior and exterior bonding applications, as well as in powertrain and electronics bonding.

LORD Corporation (A Parker Hannifin Company)

LORD Corporation specializes in adhesives and coatings designed to withstand harsh automotive conditions. The company’s structural adhesives bond metals, plastics, and composites, providing a reliable alternative to mechanical fasteners.

Huntsman Corporation

Huntsman offers a wide range of polyurethane and epoxy adhesives for structural bonding in the automotive sector. Their adhesives are valued for their toughness, thermal stability, and resistance to environmental factors, making them suitable for interior and exterior applications.

Permabond Engineering Adhesives Ltd

Permabond is a global provider of industrial adhesives for automotive and other sectors, specializing in anaerobic, cyanoacrylate, and epoxy formulations. Their adhesives are widely used in automotive component bonding, particularly in areas that require quick curing times and strong adhesion.

Trends and Innovations in Automotive Adhesives

The automotive adhesive market continues to evolve in response to changing industry demands, environmental regulations, and technological advancements. Here are some of the current trends and innovations shaping the market:

- Sustainable Adhesives: Manufacturers increasingly develop eco-friendly adhesives that reduce VOC (volatile organic compound) emissions. These adhesives meet regulatory standards and appeal to environmentally conscious consumers.

- Lightweighting and Multi-Material Bonding: Using lightweight materials like carbon fiber and aluminum has created a demand for adhesives capable of bonding dissimilar materials. Manufacturers are developing adhesives with advanced formulations that enable solid bonds between substrates and support lightweight vehicle designs.

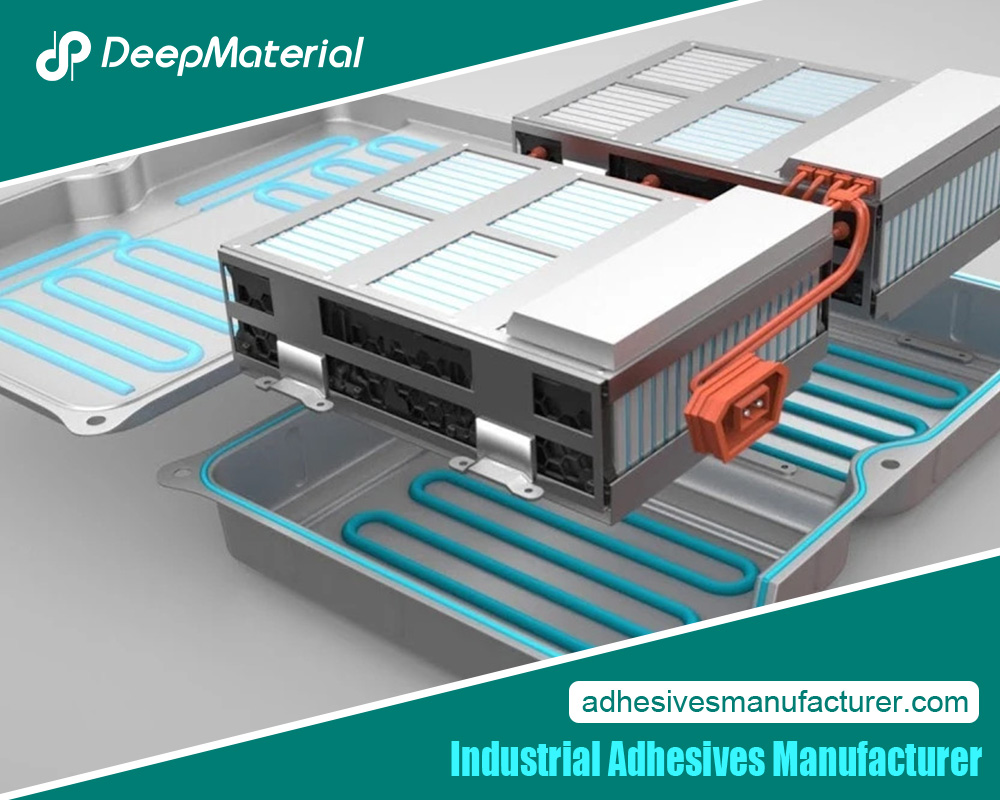

- Electrification: The rise of electric vehicles (EVs) has led to the need for adhesives that can withstand high temperatures and vibrations in battery and powertrain components. Additionally, adhesives with thermal management properties are essential for cooling EV batteries, helping to improve efficiency and safety.

- Innovative Adhesives: Some adhesives are now being developed with “smart” capabilities, such as self-healing and damage detection. These adhesives can help improve vehicle durability and reduce maintenance requirements by repairing minor damage or alerting to potential issues.

- Advanced Manufacturing Technologies: The automotive industry’s shift toward automation and Industry 4.0 practices has driven innovation in adhesive application methods. Robotic dispensing systems and automated curing technologies enable precise adhesive application, reducing waste and improving production efficiency.

Conclusion

Industrial automotive adhesive manufacturers play an essential role in modern vehicle production, offering high-performance bonding solutions that meet the automotive industry’s stringent requirements. These adhesives provide numerous benefits, including weight reduction, improved durability, and enhanced safety, making them an integral part of vehicle design and assembly. Leading manufacturers like Henkel, 3M, and Sika are at the forefront of innovation, constantly developing new products to address evolving industry needs, from lightweight and multi-material bonding to the unique challenges posed by electric vehicles. With the continued emphasis on sustainability and advanced technology, the automotive adhesive industry is set to remain a vital component of automotive manufacturing in the years to come.

For more about a complete guide to industrial automotive adhesive manufacturers: a comprehensive overview, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.