Industrial Appliance Adhesive Solution: A Comprehensive Guide to Efficiency, Durability, and Innovation

Industrial Appliance Adhesive Solution: A Comprehensive Guide to Efficiency, Durability, and Innovation

In the ever-evolving world of industrial manufacturing, the need for strong, reliable, and efficient adhesive solutions has never been more critical. Whether it’s for bonding components in heavy machinery, securing delicate parts in home appliances, or ensuring the structural integrity of large-scale industrial equipment, adhesive solutions play a pivotal role. The term “industrial appliance adhesive solution” refers to a specialized category of adhesives designed to meet the unique demands of industrial applications, offering unmatched performance in environments where traditional fastening methods may fall short.

The Role of Adhesive Solutions in Industrial Manufacturing

Enhancing Manufacturing Efficiency

In the industrial sector, efficiency is paramount. Adhesive solutions offer a streamlined approach to assembling components, significantly reducing the time and labor required compared to traditional methods like welding, screwing, or bolting.

- Reduced Assembly Time: Adhesives can bond materials in seconds or minutes, eliminating the need for lengthy setup times associated with mechanical fasteners.

- Simplified Processes: Adhesives allow for the joining of dissimilar materials without the need for additional processing, such as drilling or heat treatment.

- Automation Compatibility: Many industrial adhesives are designed for use in automated systems, further increasing production speed and consistency.

Improving Durability and Longevity

Adhesive solutions are engineered to provide long-lasting bonds that withstand the rigors of industrial use. They are crucial in ensuring that industrial appliances remain durable and reliable over extended periods.

- Resistance to Environmental Factors: Industrial adhesives are formulated to resist extreme temperatures, chemicals, and moisture, which can degrade mechanical fasteners over time.

- Vibration and Shock Absorption: Adhesives provide excellent damping properties, reducing the impact of vibrations and shocks that can lead to material fatigue and failure.

- Corrosion Prevention: Adhesives reduce the risk of corrosion, a common issue with traditional fastening methods, by eliminating metal-to-metal contact.

Cost-Effectiveness

While the initial cost of industrial adhesives might be higher than traditional fasteners, the overall savings in manufacturing costs are significant.

- Lower Material Costs: Adhesives allow using lighter, less expensive materials without compromising strength.

- Reduced Maintenance: The durability of adhesive bonds means less frequent maintenance and fewer replacements over the appliance’s lifespan.

- Energy Efficiency:Adhesives often require less energy to apply than welding or riveting, contributing to lower overall energy consumption in manufacturing.

Applications of Industrial Appliance Adhesive Solutions

Applications of Industrial Appliance Adhesive Solutions

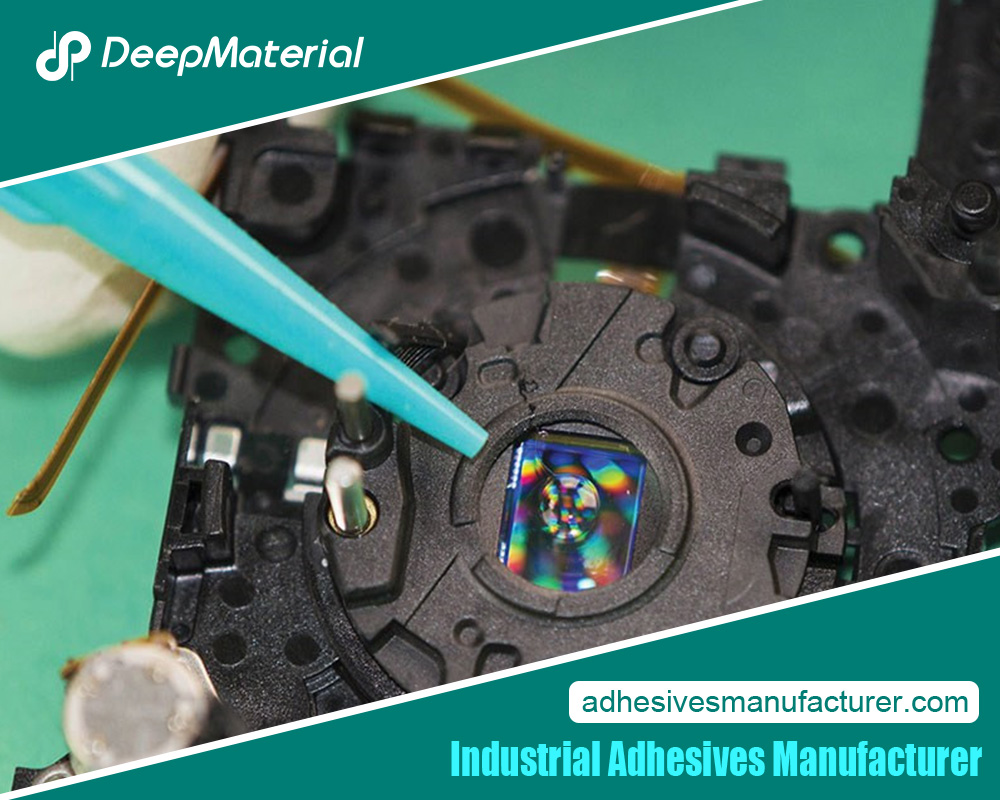

Electronics and Home Appliances

In the electronics and home appliance industries, adhesives are indispensable for assembling components that require precision and reliability.

- Component Bonding: Adhesives are used to bond circuit boards, display screens, and other delicate components where mechanical fasteners could cause damage.

- Heat Management: Thermally conductive adhesives bond heat sinks and other components, ensuring efficient heat dissipation.

- Noise Reduction: Adhesives help reduce noise and vibrations in refrigerators, washing machines, and air conditioners.

Automotive and Aerospace

The automotive and aerospace industries rely heavily on adhesive solutions for assembling lightweight, high-strength components.

- Structural Bonding: High-performance adhesives bond metal, composite, and plastic parts, contributing to the structural integrity of vehicles and aircraft.

- Weight Reduction: Adhesives enable the use of lighter materials, reducing the overall weight of vehicles and aircraft, which improves fuel efficiency.

- Environmental Resistance: Adhesives in these industries are designed to withstand extreme temperatures, UV exposure, and chemical exposure, ensuring long-term durability.

Heavy Machinery and Equipment

In heavy machinery and industrial equipment construction, adhesive solutions provide the strength and reliability needed for demanding applications.

- Load-Bearing Joints: Industrial adhesives are used in load-bearing joints where traditional fasteners may fail under high stress.

- Sealing and Insulation: Adhesives are often used to seal joints and insulate components, protecting them from environmental factors and enhancing energy efficiency.

- Maintenance and Repair: Adhesives are also used to maintain and repair machinery, providing quick and effective solutions for damaged parts.

Types of Industrial Adhesive Solutions

Epoxy Adhesives

Epoxy adhesives are among the most widely used in industrial applications due to their exceptional strength and versatility.

- High Bond Strength: Epoxy adhesives offer excellent adhesion to various materials, including metals, plastics, and composites.

- Chemical Resistance: Epoxy adhesives are highly resistant to chemicals, making them ideal for applications in harsh environments.

- Customizable Properties: Epoxies can be formulated to meet specific requirements, such as fast curing times or high-temperature resistance.

Polyurethane Adhesives

Polyurethane adhesives are known for their flexibility and impact resistance, making them suitable for dynamic applications.

- Flexibility: Polyurethane adhesives maintain flexibility after curing, which is crucial for movement or vibration applications.

- Strong Adhesion to Various Substrates: These adhesives bond well to various materials, including wood, metal, and plastic.

- Weather Resistance: Polyurethane adhesives resist moisture and UV exposure, making them suitable for outdoor applications.

Silicone Adhesives

Silicone adhesives are prized for their high-temperature resistance and excellent electrical insulation properties.

- Heat Resistance: Silicone adhesives can withstand extreme temperatures, making them ideal for applications in the automotive and aerospace industries.

- Electrical Insulation: These adhesives are non-conductive and are often used in electronics to bond and insulate components.

- Flexibility and Durability: Silicone adhesives remain flexible and durable, even in harsh environmental conditions.

Innovations in Industrial Appliance Adhesive Solutions

Nanotechnology in Adhesives

Integrating nanotechnology into adhesive formulations leads to adhesives with enhanced properties, such as increased strength, conductivity, and resistance to environmental factors.

- Improved Bonding Strength: Nanoparticles can enhance the mechanical properties of adhesives, leading to more robust and durable bonds.

- Conductive Adhesives: Nanomaterials create adhesives with improved electrical conductivity, which is crucial for electronics and electrical applications.

- Self-Healing Adhesives: Some nanotechnology-enhanced adhesives can repair themselves after damage, extending the life of the bonded components.

Eco-Friendly Adhesive Solutions

As industries become more environmentally conscious, there is a growing demand for eco-friendly adhesive solutions.

- Biodegradable Adhesives: New formulations that break down naturally over time are being developed, reducing environmental impact.

- Low-VOC Adhesives:Adhesives with low volatile organic compound (VOC) emissions are becoming more common, contributing to healthier working environments and less environmental pollution.

- Recyclable Adhesives:Some adhesives are designed to be easily removable, facilitating the recycling of bonded materials.

Smart Adhesives

Innovative adhesives are a new frontier in adhesive technology, offering functionalities beyond bonding.

- Temperature-Responsive Adhesives: These adhesives change their properties in response to temperature changes, providing adaptive bonding strength.

- Adhesives with Sensors: Some adhesives are embedded with sensors that monitor the integrity of the bond, alerting manufacturers to potential failures before they occur.

- Conductive and Magnetic Adhesives: Smart adhesives can also be designed to conduct electricity or respond to magnetic fields, opening up new possibilities for their application in advanced technologies.

Choosing the Right Adhesive Solution

Understanding Application Requirements

Selecting the right industrial appliance adhesive solution requires thoroughly understanding the specific application requirements.

- Material Compatibility: It is essential to choose an adhesive that is compatible with the materials being bonded, considering factors such as surface energy, porosity, and flexibility.

- Environmental Conditions: The operating environment, including temperature, humidity, and exposure to chemicals, should guide the choice of adhesive.

- Load-Bearing Capacity: For structural applications, the adhesive must be capable of withstanding the mechanical stresses and loads that will be applied.

Collaboration with Suppliers

Working closely with adhesive suppliers can help manufacturers find the most suitable solution.

- Technical Support: Suppliers often provide technical support to help manufacturers select the suitable adhesive and optimize the application process.

- Custom Formulations: Suppliers may offer custom formulations to meet specific performance criteria for unique applications.

- Testing and Validation:Collaborating with suppliers can also involve testing and validating the adhesive in the application environment, ensuring it meets all requirements.

Conclusion

Conclusion

The industrial appliance adhesive solution industry is a critical component of modern manufacturing, providing the bonding strength, durability, and efficiency needed in today’s fast-paced industrial environments. From reducing assembly times to enhancing product durability and longevity, adhesive solutions offer a range of benefits that make them indispensable in a variety of applications.

For more about the industrial appliance adhesive solution: a comprehensive guide to efficiency, durability, and innovation, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.