Industrial Sealant Manufacturers: Innovating to Meet Evolving Needs

Industrial Sealant Manufacturers: Innovating to Meet Evolving Needs

Industrial sealants are critical in various manufacturing and construction applications, providing essential sealing, bonding, and protection capabilities. As industries continue to evolve, industrial sealant manufacturers are rising to the challenge by developing innovative new products and solutions to meet their customers’ changing needs.

The Growing Importance of Industrial Sealants

Industrial sealants fill, seal, and protect joints, gaps, and interfaces in various industrial settings. They are formulated to provide a durable, long-lasting barrier against air, water, dust, and other environmental elements that could otherwise compromise the integrity and performance of a system or structure. Some of the critical applications for industrial sealants include:

- Automotive manufacturing – Sealing body panels, windows, doors, and other components to prevent leaks and improve structural integrity.

- Aerospace engineering – Sealing aircraft fuselages, wings, and other critical components to maintain airtightness and withstand extreme environmental conditions.

- Building construction – Sealing joints, gaps, and penetrations in walls, floors, and roofs to improve energy efficiency and prevent water intrusion.

- Heavy equipment – Sealing hydraulic systems, engine components, and other parts to protect against contaminants and extend equipment lifespan.

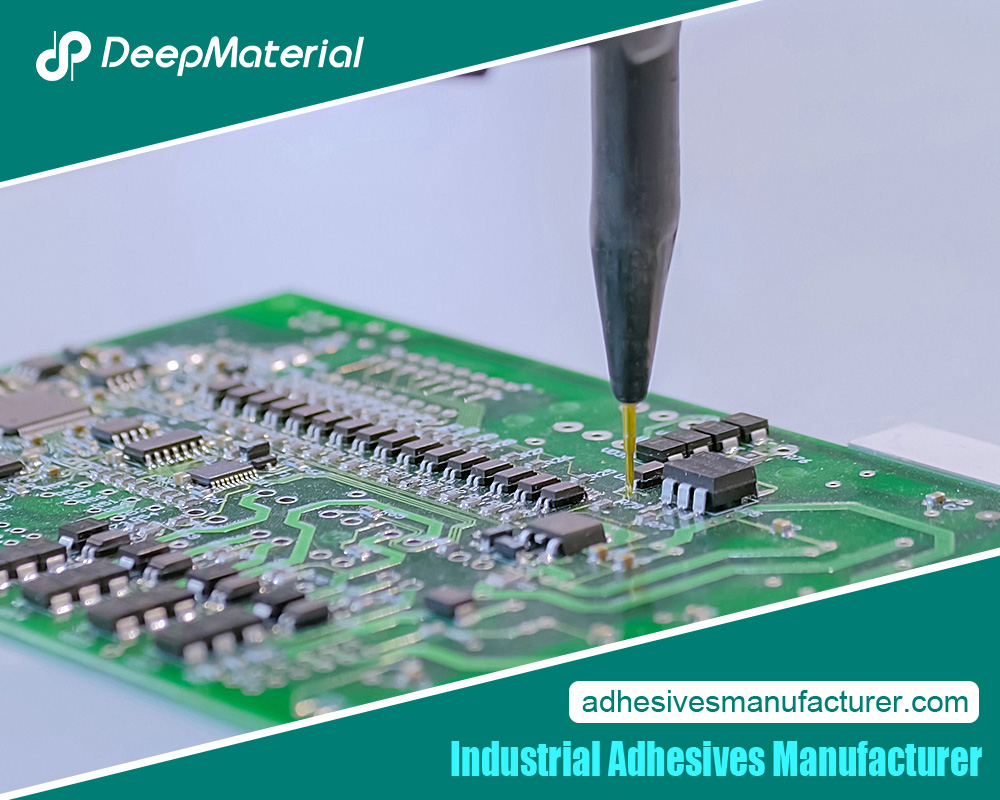

- Electronics and electrical systems – Sealing circuit boards, connectors, and enclosures to shield sensitive components from moisture, dust, and other environmental hazards.

The demand for advanced industrial sealants is growing as industries continue to evolve. Manufacturers are under increasing pressure to develop products that meet more stringent performance requirements, comply with new environmental regulations, and provide enhanced functionality.

Innovations in Industrial Sealant Technology

To keep pace with these changing needs, industrial sealant manufacturers invest heavily in research and development to create innovative new products and solutions. Some of the critical areas of innovation include:

High-Performance Sealants

One of the primary areas of focus for industrial sealant manufacturers is the development of high-performance sealants that can withstand increasingly demanding operating environments. This includes sealants that resist extreme temperatures, harsh chemicals, abrasion, and other challenging conditions.

For example, aerospace and defense applications often require sealants that can maintain their integrity at temperatures ranging from -65°C to 260°C while also providing excellent resistance to fuels, hydraulic fluids, and other corrosive substances. Manufacturers like Henkel, 3M, and Dow have responded by developing specialized aerospace-grade sealants that can meet these stringent performance requirements.

Similarly, in the automotive industry, there is a growing demand for sealants that can withstand the high temperatures and vibrations encountered in engine compartments while also providing robust sealing capabilities. Manufacturers like Sika and Bostik have introduced innovative sealant formulations that can address these challenges.

Sustainable and Environmentally-Friendly Sealants

As environmental regulations and sustainability concerns continue to shape industrial practices, sealant manufacturers are also focused on developing more eco-friendly products. This includes sealants formulated with reduced volatile organic compound (VOC) content and those made from renewable or recycled materials.

For example, Tremco, a leading manufacturer of construction sealants, has introduced a line of high-performance sealants made from 100% silicone, free of solvents, isocyanates, and other potentially harmful chemicals. Similarly, Bostik has developed a range of “green” sealants that utilize plant-based and recycled raw materials, reducing their environmental impact.

Multifunctional and Smart Sealants

In addition to high-performance and sustainable formulations, sealant manufacturers are also exploring ways to incorporate additional functionality into their products. This includes the development of “smart” sealants that can sense and respond to changes in their environment, as well as sealants that can provide enhanced bonding, insulation, or other specialized capabilities.

For instance, some manufacturers have introduced sealants that can detect and self-heal minor cracks or damage, helping extend the sealed components’ lifespan. Others have developed sealants that can conduct electricity or provide electromagnetic shielding, addressing the growing need for integrated solutions in the electronics and electrical industries.

The Role of Automation and Digitalization

As industrial sealant manufacturers strive to meet the evolving needs of their customers, they are also leveraging the power of automation and digitalization to improve their production processes and supply chain operations.

Many leading sealant manufacturers have invested in advanced manufacturing technologies, such as robotic dispensing systems and automated mixing and packaging equipment, to increase efficiency, improve product quality, and reduce waste.

These automated systems can precisely control the application of sealants, ensuring consistent and reliable results while minimizing the risk of human error. In addition, sealant manufacturers are increasingly adopting digital technologies to enhance their operations and customer service.

This includes using cloud-based enterprise resource planning (ERP) systems to streamline inventory management, order processing, and supply chain logistics, as well as integrating data analytics and predictive maintenance tools to optimize production and maintenance schedules.

Collaboration and Partnerships

Many industrial sealant manufacturers are also forging strategic partnerships and collaborations with their customers, suppliers, and competitors to stay ahead of the curve in this rapidly evolving industry. By working closely with their customers, sealant manufacturers can better understand their specific needs and challenges, enabling them to develop more tailored solutions.

This collaborative approach also allows for co-creating new products and testing innovative prototypes in real-world applications. Similarly, partnerships with raw material suppliers and other industry players can help sealant manufacturers access new technologies, share best practices, and leverage complementary capabilities to drive innovation.

For example, some manufacturers have teamed up with materials science experts to develop advanced polymer formulations, while others have collaborated with software providers to integrate digital tools into their operations.

The Future of Industrial Sealants

As industries continue to evolve and new challenges emerge, the role of industrial sealant manufacturers will only become more critical. By investing in research and development, embracing automation and digitalization, and fostering collaborative partnerships, these manufacturers can meet the growing demand for innovative, high-performance, and sustainable sealant solutions.

Looking ahead, some of the key trends and developments that are likely to shape the future of industrial sealants include:

- Increased focus on sustainability and environmental responsibility, emphasizing sealants made from renewable, recycled, or biodegradable materials.

- Technological advancements in innovative and multifunctional sealants incorporate self-healing, electrical conductivity, and enhanced insulation properties.

- Expanded use of data analytics and predictive maintenance to optimize sealant performance and extend the lifespan of industrial equipment and infrastructure.

- Closer collaboration between sealant manufacturers, their customers, and other industry stakeholders to drive innovation and address emerging challenges.

By staying attuned to these trends and pushing the boundaries of sealant technology, industrial sealant manufacturers will play a vital role in supporting the growth and evolution of a wide range of industries in the years to come.

For more about the best industrial sealant manufacturers: innovating to meet evolving needs, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.