Industrial Adhesive Solutions Manufacturers

Industrial Adhesive Solutions Manufacturers

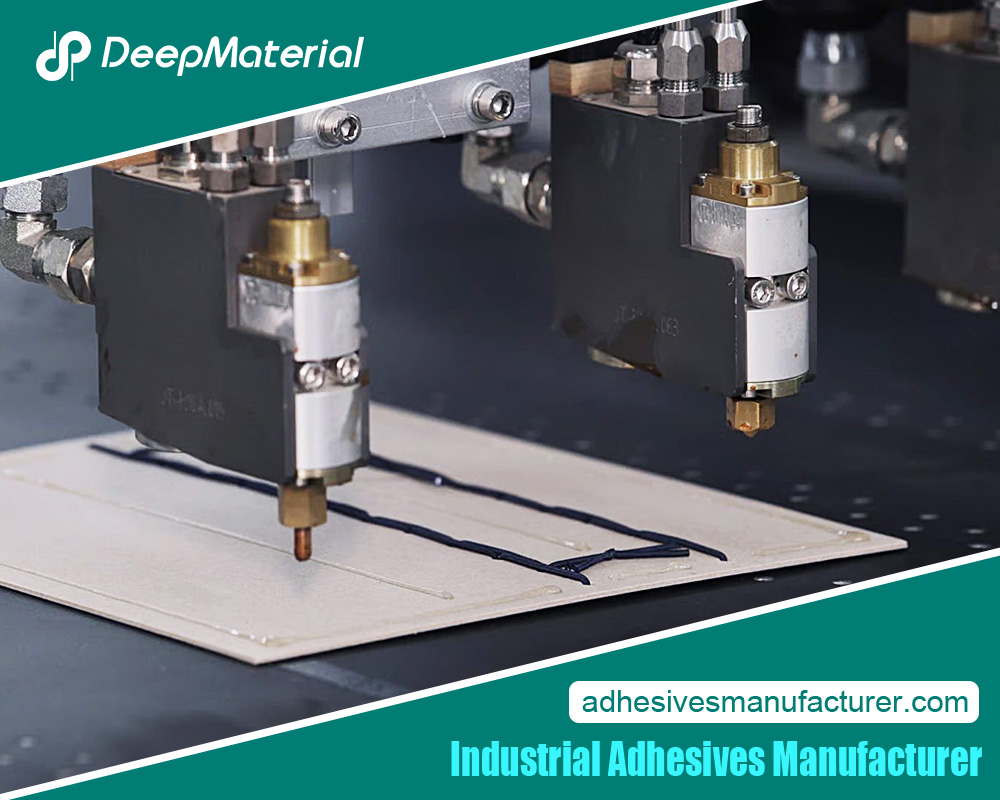

Industrial adhesives are indispensable in modern manufacturing processes, revolutionizing how materials are bonded and assembled across various industries. These adhesives are vital in enhancing product durability, improving efficiency, and enabling innovative design solutions.

Key players in the industrial adhesive solutions manufacturing sector, such as Master Bond, Adhesives Technology Corp., and Henkel Adhesives, are at the forefront of developing high-quality adhesive systems tailored to the diverse needs of industries like automotive, aerospace, electronics, and construction.

Their impact extends beyond mere bonding; these manufacturers contribute significantly to products’ quality, reliability, and sustainability in today’s manufacturing landscape.

The Evolution of Industrial Adhesives

The evolution of industrial adhesives traces back to ancient times when primitive forms of adhesives like tree sap, beeswax, and animal glue were used to bond objects together. Over millennia, adhesives have undergone significant advancements, leading to the development of a multi-billion dollar industry that plays a crucial role in modern manufacturing processes.

Historically, the first known use of a substance as an adhesive dates back to 4000 B.C., when tree sap was used to repair pottery and clay vessels. The Greeks and Romans refined animal glues between 1-500 A.D., incorporating substances like egg whites, milk, and animal hides to enhance bond strength. The 1500s saw the rise of glue as a means of assembly, coinciding with the growth of woodworking and furniture making in society. During the Industrial Revolution in the 1920s, glue manufacturing became integral, forming new materials that facilitated easier adhesive production.

The synthesis of the first plastic polymer, cellulose nitrate, marked a significant milestone in adhesive technology. World War II further accelerated the growth of the synthetic adhesive industry, prompting manufacturers to consider factors like flexibility, toughness, cure time, and resistance to temperature and chemicals in adhesive formulations. Today, industrial adhesives are used across countless applications, replacing traditional fastening methods like stitching and stapling.

The industry has rapidly expanded with diverse adhesive types developed to meet specific requirements in bonding materials like plastics, wood, metals, and mineral substances. The evolution of adhesive technologies has been instrumental in enhancing manufacturing processes, driving innovation, and improving product quality and efficiency across various sectors.

Types of Industrial Adhesives

Types of Industrial Adhesives

Acrylic Adhesives

Acrylic adhesives are known for their fast bonding capabilities and excellent adhesion to various surfaces, including metals, plastics, and glass. They are commonly used in the automotive, electronics, and construction industries. Acrylic adhesives come in solvent-based and emulsion varieties, providing versatility in their application. Leading manufacturers of acrylic adhesives include Henkel Adhesives, with their LOCTITE® brand, and Adhesives Technology Corp., which offers a range of high-performance acrylic adhesive solutions.

Epoxy Adhesives

Epoxy adhesives are widely used in automotive, aerospace, and plywood manufacturing industries due to their quick cure time and ability to form strong bonds on concrete surfaces. These adhesives are known for their durability, chemical resistance, and ability to withstand high temperatures. Notable manufacturers specializing in epoxy adhesive solutions include Master Bond, which offers a diverse range of epoxy systems, and Henkel Adhesives, with their LOCTITE® epoxy products.

Polyurethane Adhesives

Polyurethane adhesives are known for their versatility and high-performance characteristics. They can be either thermoplastic or thermoset, providing various construction, transportation, and packaging applications. Key manufacturers of polyurethane adhesives include Adhesives Technology Corp., which offers a comprehensive portfolio of polyurethane-based solutions, and Henkel Adhesives, with their LOCTITE® polyurethane adhesive line.

Silicone Adhesives

Silicone adhesives are valued for their flexibility, temperature resistance, and ability to bond to various materials, including metals, plastics, and glass. They are commonly used in applications where flexibility and weather ability are essential, such as the construction and electronics industries. Prominent manufacturers offering silicone adhesive solutions include Master Bond, known for its high-quality silicone-based adhesives, and Adhesives Technology Corp., which provides a range of silicone-based products.

Leading Manufacturers in the Industry

Master Bond

Master Bond is a renowned company specializing in high-quality adhesive systems catering to various industries. The company prides itself on its innovative product range, which includes epoxies, silicones, U.V.-curable, and LED-curable systems. Master Bond has established a strong industry reputation for providing reliable and durable adhesive solutions that meet the stringent requirements of various applications. Their commitment to excellence and customer satisfaction has positioned them as a leading manufacturer in the adhesive industry.

Case Studies:

- Aerospace Industry: Master Bond’s aerospace-grade adhesives have been instrumental in bonding critical components in aircraft structures, ensuring structural integrity and reliability under extreme conditions.

- Electronics Sector: The company’s electronic adhesives have facilitated the assembly of intricate electronic devices, providing thermal conductivity and electrical insulation for optimal performance.

Adhesives Technology Corp.

Adhesives Technology Corp. is a prominent industrial adhesive manufacturing sector player with a rich history and diverse product portfolio. The company is known for its high-quality adhesive solutions, including acrylic, epoxy, and polyurethane adhesives, tailored to meet the specific needs of various commercial systems. Adhesives Technology Corp. has built a strong market presence through its commitment to product excellence, reliability, and customer satisfaction.

Testimonials:

- “Adhesives Technology Corp. has been our trusted partner for years, providing us with reliable adhesive solutions that have enhanced our manufacturing processes and product quality.”

- “The exceptional performance of Adhesives Technology Corp.’s products has significantly improved our operational efficiency and overall production output.”

Henkel Adhesives

Henkel Adhesives is a leading manufacturer known for its innovative industrial adhesive products under the renowned LOCTITE® brand. The company has a significant market share in the adhesive industry, offering a wide range of products designed to meet the diverse needs of industries like automotive, aerospace, and electronics. Henkel Adhesives is recognized for its commitment to innovation, sustainability, and product quality, making it a preferred choice for industrial adhesive solutions.

Sustainability Initiatives:

- Henkel Adhesives has been at the forefront of sustainability, integrating eco-friendly practices and materials into their adhesive formulations to reduce environmental impact.

- The company’s sustainability initiatives focus on developing effective and environmentally responsible adhesives, aligning with the growing demand for sustainable manufacturing practices.

Applications of Industrial Adhesives

Industrial adhesives have various applications, enhancing product quality, efficiency, and durability. Here’s a detailed exploration of industrial adhesive applications in key sectors:

Automotive Industry

Industrial adhesives are crucial in the automotive industry, where they are used to bond various components together, ensuring structural integrity and reliability. They are instrumental in applications such as:

- Body and chassis assembly: Adhesives bond metal and plastic components together, providing a solid and durable bond that withstands the rigors of road use.

- Sealing and gasketing: Industrial adhesives seal gaps and joints in the vehicle, preventing leaks and ensuring a watertight seal.

- Interior trim and upholstery: Adhesives bond interior components like carpets, seats, and trim, providing a durable and long-lasting bond.

Aerospace Industry

The aerospace industry relies heavily on industrial adhesives for bonding and sealing critical components, ensuring the safety and reliability of aircraft and spacecraft. Key applications include:

- Structural bonding: Adhesives bond lightweight materials like carbon fiber and aluminum, providing a solid and durable bond that withstands extreme conditions.

- Sealing and gasketing: Industrial adhesives seal gaps and joints in aircraft and spacecraft, preventing leaks and ensuring a watertight seal.

- Electrical and electronic bonding: Adhesives bond electrical and electronic components, ensuring reliable connections and preventing electrical failures.

Electronics Industry

Industrial adhesives play a vital role in the electronics industry, where they bond and assemble various components, ensuring reliable connections and preventing electrical failures. Key applications include:

- PCB assembly: Adhesives bond printed circuit boards (PCBs) to other components, providing a solid, durable bond that withstands environmental conditions.

- Component bonding: Industrial adhesives bond various electronic components, ensuring reliable connections and preventing electrical failures.

- Sealing and encapsulation: Adhesives seal and encapsulate electronic components, protecting them from environmental factors like moisture and temperature.

Construction Industry

Industrial adhesives are used extensively in the construction industry to bond and assemble various materials, ensuring structural integrity and durability. Key applications include:

- Building insulation: Adhesive bond insulation materials like fiberglass and foam provide a solid, durable bond that withstands environmental conditions.

- Flooring and tiling: Industrial adhesives bond flooring and tiling materials, ensuring a solid, durable bond that withstands foot traffic and environmental conditions.

- Roofing and waterproofing: Adhesives bond roofing materials like shingles and membranes, providing a watertight seal and ensuring the roof’s integrity.

Packaging Industry

Industrial adhesives are used in the packaging industry to bond and seal various materials, ensuring the integrity and security of packaged goods. Key applications include:

- Labeling and packaging: Adhesives bond labels and packaging materials together, ensuring a solid, durable bond that withstands environmental conditions.

- Sealing and gasketing: Industrial adhesives seal gaps and joints in packaging materials, preventing leaks and ensuring a watertight seal.

- Bonding and assembly: Adhesives bond and assemble various packaging components, ensuring reliable connections and preventing failures.

Industrial adhesives are crucial in various industries, providing effective bonding solutions for multiple applications. Their versatility, durability, and reliability make them essential to modern manufacturing processes.

Impact of Industrial Adhesives on Manufacturing

Industrial adhesives have revolutionized manufacturing processes by offering efficient, cost-effective, durable bonding solutions across various industries. These adhesives have transformed traditional assembly methods, providing numerous benefits that enhance productivity and product quality. Let’s delve into how industrial adhesives have impacted manufacturing and explore case studies highlighting their efficiency, cost-effectiveness, and durability.

Revolutionizing Manufacturing Processes

Industrial adhesives have revolutionized manufacturing in the following ways:

- Efficiency: Adhesives streamline assembly processes, reducing production time and labor costs by eliminating the need for complex mechanical fastening methods.

- Cost-Effectiveness: Adhesives offer a cost-effective bonding solution by reducing material waste, energy consumption, and the need for additional components.

- Durability: Industrial adhesives provide durable bonds that withstand environmental conditions, vibrations, and stress, ensuring the longevity and reliability of assembled products.

Case Studies

- Automotive Industry: Using industrial adhesives in automotive manufacturing has significantly improved efficiency and durability. Case studies show that adhesives have enhanced structural integrity, reduced assembly time, and minimized material waste, leading to cost savings and increased productivity.

- Electronics Sector: Industrial adhesives have revolutionized the assembly of electronic components, ensuring reliable connections and preventing electrical failures. Case studies demonstrate that adhesives have improved production efficiency, reduced defects, and enhanced product performance in electronic devices.

- Construction Industry: Industrial adhesives have transformed bonding processes for materials like insulation, flooring, and roofing in the construction sector. Case studies reveal that adhesives have accelerated construction timelines, improved structural strength, and reduced maintenance costs by providing durable and long-lasting bonds.

Industrial adhesives have profoundly impacted manufacturing processes by revolutionizing assembly techniques, enhancing efficiency, and improving product quality. Adhesive solutions’ efficiency, cost-effectiveness, and durability have made them indispensable in modern manufacturing, driving innovation and progress across industries.

Future Trends in Industrial Adhesive Manufacturing

Emerging Technologies and Materials

Several emerging technologies and innovative materials are shaping the future of industrial adhesive manufacturing:

- Bio-based and Sustainable Adhesives: A growing focus is on developing adhesives derived from renewable, eco-friendly sources like plant-based materials and agricultural waste. These sustainable adhesives aim to reduce the environmental impact of traditional petroleum-based formulations.

- Innovative Adhesives with Sensor Technology: Integrating sensor technology into adhesives enables the development of “smart” adhesives that can monitor performance, detect defects, and provide real-time data for predictive maintenance.

- 3D Printed Adhesive Structures: Advancements in 3D printing allow the fabrication of customized adhesive structures tailored to specific applications, offering enhanced design flexibility and performance.

- Adhesives for Lightweight Materials: As industries like automotive and aerospace prioritize weight reduction, adhesives are crucial in enabling lightweight composite materials by providing solid and durable bonds.

Sustainability Initiatives

Industrial adhesive manufacturers are actively pursuing sustainability initiatives to address the growing demand for environmentally responsible products:

- Renewable and Recyclable Adhesives: Companies are investing in developing adhesives made from renewable raw materials and designing recyclable or compostable formulations, aligning with the principles of a circular economy.

- Reduced Environmental Impact: Adhesive manufacturers are focusing on improving the environmental footprint of their production processes, including reducing energy consumption, minimizing waste, and adopting green chemistry practices.

- Compliance with Regulations: Adhesive producers closely monitor and adapt to evolving regulations related to chemical usage, emissions, and waste management to ensure their products meet stringent environmental standards.

Conclusion

Industrial adhesive solutions manufacturers play a pivotal role in modern manufacturing, enabling innovation, enhancing efficiency, and driving progress across various industries. As the demand for sustainable, high-performance adhesives grows, leading manufacturers are at the forefront of developing cutting-edge technologies and eco-friendly solutions. By leveraging industrial adhesive manufacturers’ expertise and innovative capabilities, industries can unlock new opportunities for improved product quality, increased productivity, and reduced environmental impact. As the manufacturing landscape evolves, the collaboration between sectors and adhesive solution providers will be crucial in shaping a more sustainable and efficient future.

For more about the best industrial adhesive solutions manufacturers, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.