How an industrial epoxy coatings manufacturer can add value to your production facility

How an industrial epoxy coatings manufacturer can add value to your production facility

Industrial epoxy coatings have a wide range of applications. How and when they are applied depends on the specific requirements of the application. These are specially engineered surface treatment products that come with various benefits that are highly in demand in industrial environments. Industrial epoxy costings have desirable properties like anti-corrosion, anti-slip, chemical resistance, high load resistance, and so on.

What is an industrial epoxy coating?

What is an industrial epoxy coating?

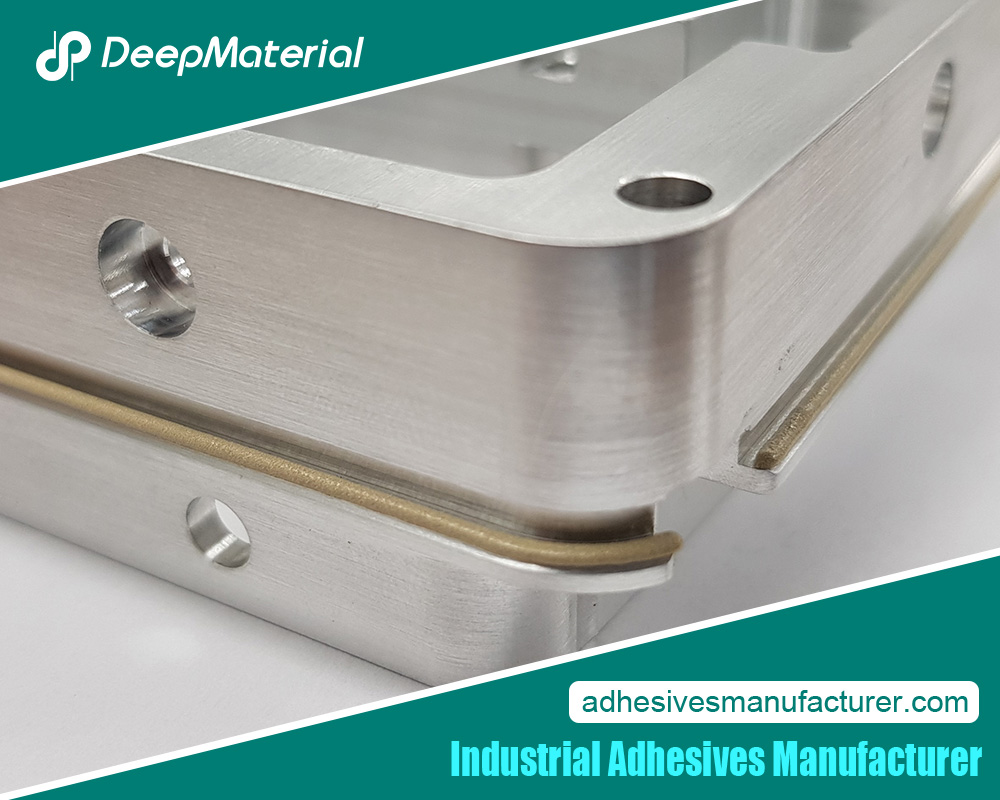

An industrial epoxy coating is a chemical formulation that is applied for protective surface treatment. This type of epoxy coating is usually applied in both commercial and industrial environments. An epoxy coating product is made up of a mixture of hardening compounds, a thermosetting polymer, and an epoxy resin. If the coating is applied on a product surface, it forms a durable layer that is resistant to chemicals.

What are the benefits of industrial coatings?

Industrial coatings are a valuable product that is applied in various conditions. These special products have several benefits such as:

- Durability:Industrial epoxy coatings form a long-lasting and strong surface that can withstand intense loads from people and machinery. They also have excellent chemical resistance properties.

- Chemical Resistance:Industrial epoxies offer great chemical resistance against solvent oils, acids, and substances with potential corrosive properties.

- Aesthetic enhancement:Industrial epoxy coatings are supplied in a variety of colours. They can be applied when it comes to improving the final appearance of surfaces or floors.

- Easy maintenance:Industrial epoxy coatings can be cleaned and maintained easily. This is why they are highly applicable in environments where cleanliness is much needed.

- Safety:Industrial epoxies are surface coatings that are known to offer amazing safety properties. These paints can be engineered to provide anti-slip functions. Thus, they are great when it comes to improving the safety of industrial spaces.

What are the most common applications of industrial epoxy coatings?

Industrial epoxy coatings have a wide range of benefits that make them suitable for several applications. They have durability, protective, and chemical-resisting properties. This is why they are suitable for a wide range of applications. They can be applied in the following areas:

Flooring: They are used to protect various industrial flooring surfaces. The coatings can also enhance the durability of such floors. Examples of such flooring include garages, factories, and warehouses.

Structural steel: Industrial coatings can be used for the protection of structural steel against corrosion. In addition, it can also be used to extend the durability of buildings, bridges, and many other structures.

Marine applications: These engineering coatings can also be used in various marine structures such as boats, ships, vessels, submarines, and so on. This is used to safeguard the marine structure against possible corrosion, especially in water environments that contain harsh salts.

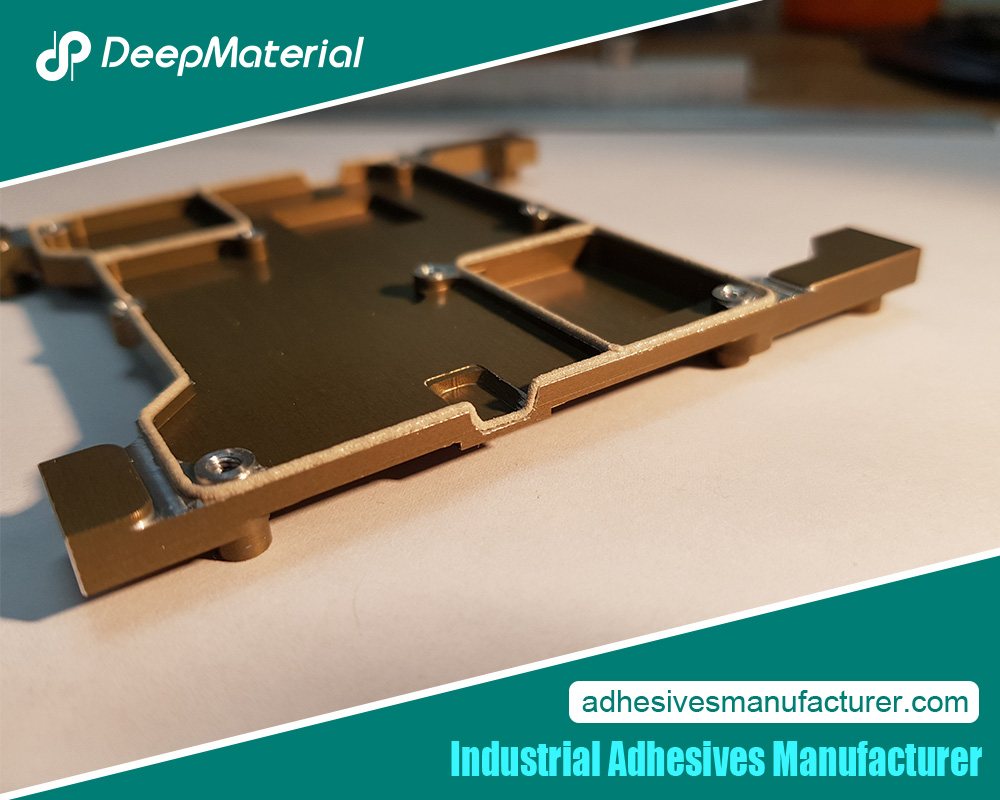

Electronics: Epoxy coatings can also be used in the assembly of electronic products and PCBs. The industrial coatings provide excellent protection against dust, chemicals, and moisture.

Chemical processing: Epoxy coatings are used in chemical plants where they can be used as a form of anti-corrosion protection in storage tanks and other equipment.

Hospitals: Industrial epoxy costings are useful when it comes to flooring surface finishes in healthcare facilities. These coatings are used to provide hygienic flooring for many clean areas and operating rooms in hospitals.

Who is an industrial epoxy coating manufacturer

How an industrial coatings manufacturer adds value to your production facility

With an industrial epoxy coatings manufacturer, you can easily add a lot of value to your production facility. These include:

- High-quality adhesive products:An industrial epoxy coatings manufacturer usually specializes in the manufacturing of epoxy coatings. These are industrial chemicals that are applied in various industrial conditions to ensure performance and durability.

- Customization: These manufacturers can create custom epoxy coatings based on the requirements of the customer. They can help your production facility produce precise epoxy coatings according to specific requirements such as chemical resistance, thickness, and colour.

- Expertise:These manufacturers have a combination of expertise and technology to produce the best epoxy coatings. This means that they have the right knowledge and information on the best epoxy coatings used for different industrial applications.

- Cost-effective products:Manufacturers of industrial epoxy contains are known for producing cost-effective paints. These are products that can help preserve and extend the lifespan of the surface or the equipment. In addition, they can also help reduce both replacement and maintenance costs.

- Enhanced safety property: With epoxy coatings, you can easily improve the safety properties of certain areas. This special coating makes it possible for the special properties of the product to be improved. This includes fire resistance, chemical resistance, and slip resistance. Which makes it easy to make work environments safer.

- Environmental compliance: An industrial epoxy coatings manufacturer can help your production facility by producing environmentally-compliant products. These may be epoxy coatings that are Eco-friendly and promote sustainable green products. Environmentally-friendly products help your manufacturing facility to meet strict environmental regulations.

- Longevity:When it comes to the application of durable epoxy coatings, manufacturers can come up with the right product. When the epoxy coating is applied it can extend the life of the surface. The material. It is used to protect these materials from damage, wear, and tear.

- Technical support:Epoxy coatings manufacturers usually help their customers with the needed level of technical support that they need. The technical support provided can be anything from troubleshooting to application guidance.

- Aesthetics:Your epoxy coatings manufacturer can help your epoxy coating product achieve the right level of aesthetics. With these enhanced epoxy products, you can easily beautify the surfaces of various by choosing from numerous available finishes from the matte to the glossy option.

- Warranty:Warranties are very important for your production facility, to give your customers the needed level of assurance. A lot of manufacturers offer various warranties to keep their customers satisfied.

How to choose the right industrial epoxy coatings manufacturer

How to choose the right industrial epoxy coatings manufacturer

You need to choose the right industrial epoxy coatings manufacturer for your production facility. This is how you get access to products of high quality. These are products that can deliver value in the long term while also meeting specific requirements of your production facility.

For more about choosing the industrial epoxy coatings manufacturer,you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.