Exploring Industrial Adhesive Solutions Manufacturers: Innovators Behind Stronger Bonds

Exploring Industrial Adhesive Solutions Manufacturers: Innovators Behind Stronger Bonds

The role of adhesives in the fast-paced world of manufacturing, construction, automotive, electronics, and various other industries cannot be overstated. Industrial adhesive solutions are crucial in multiple applications, offering functional and structural integrity to products and processes. As these industries evolve and demand more efficient, reliable, and sustainable bonding solutions, the role of industrial adhesive solutions manufacturers becomes even more vital. These manufacturers are at the forefront of innovation, producing adhesives that enhance productivity, durability, and safety.

This article will explore the importance of industrial adhesives, the types of adhesive solutions offered by manufacturers, the key players in the market, and the future trends shaping the industry. By understanding the role and impact of these manufacturers, businesses can make more informed decisions when choosing adhesives for their operations.

The Role of Industrial Adhesives in Manufacturing

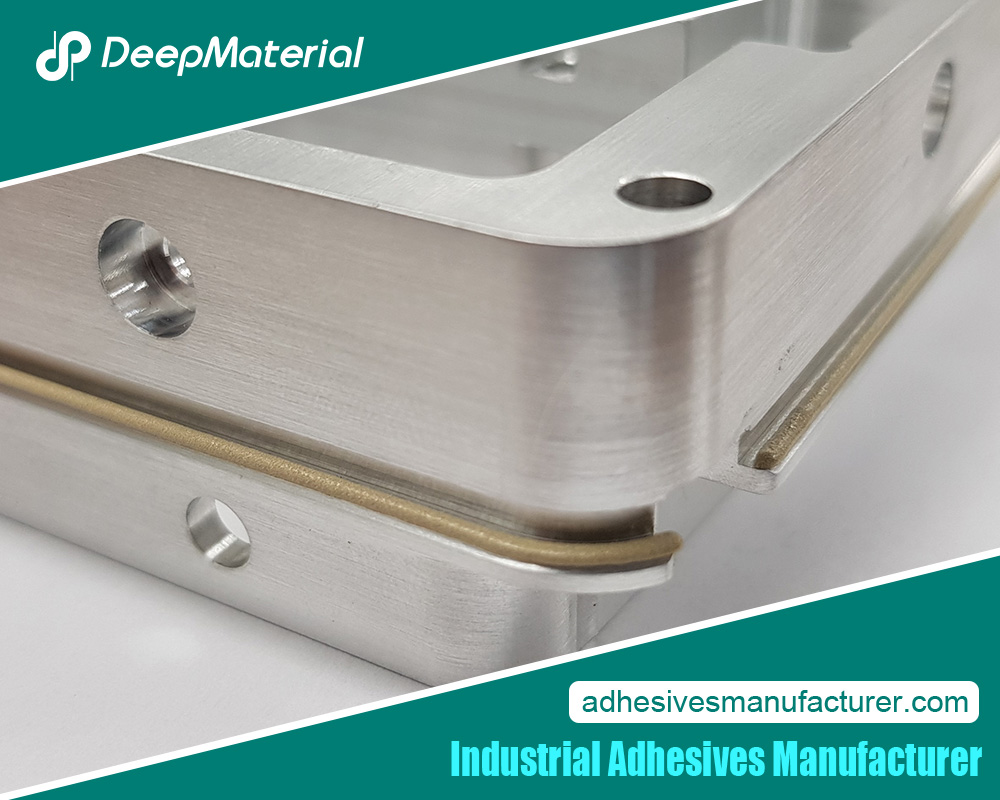

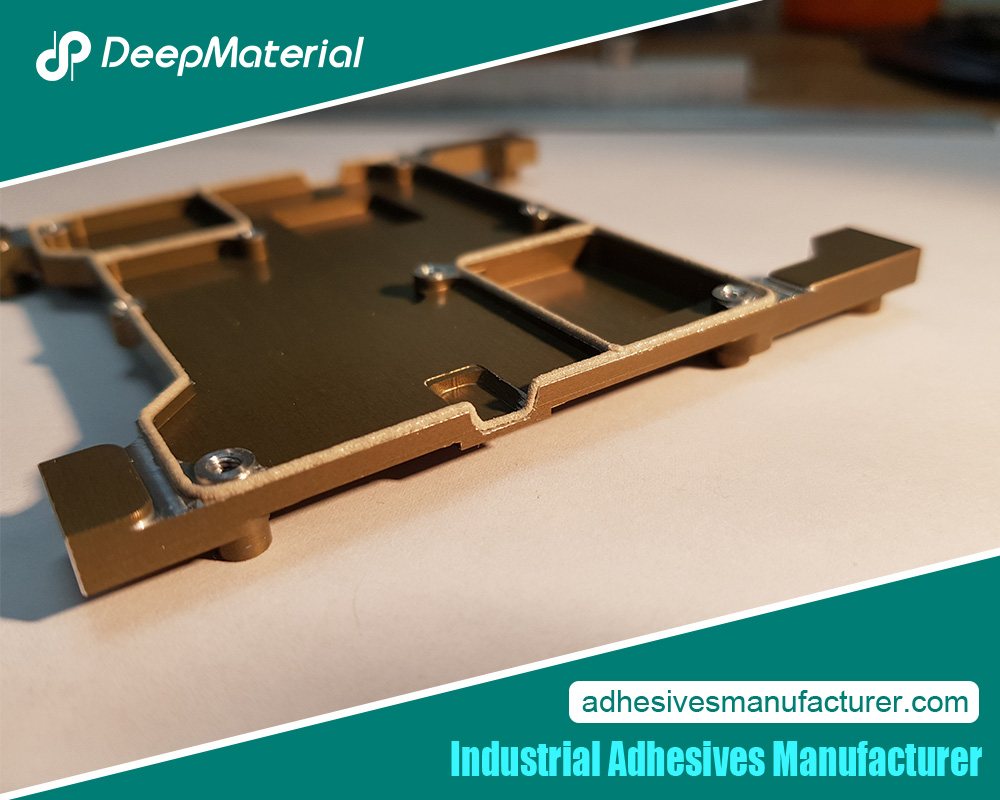

Adhesives have evolved from simple glue to highly advanced, specialized solutions that cater to industries’ diverse needs. Industrial adhesives are designed to create strong, lasting bonds between different substrates, such as metals, plastics, glass, or ceramics. These adhesives help manufacturers achieve optimal product assembly, packaging, and surface finishing results.

Types of Industrial Adhesive Solutions

Industrial adhesive solutions manufacturers produce various adhesives designed for specific applications. Some of the most common types include:

- Epoxy Adhesives:Known for their excellent bonding strength and resistance to environmental factors, epoxy adhesives are used in applications requiring high-performance bonds, such as in the aerospace, automotive, and electronics industries.

- Polyurethane Adhesives:These adhesives are flexible, durable, and resistant to chemicals and weathering, making them suitable for applications in the automotive, construction, and furniture industries.

- Acrylic Adhesives:Acrylic adhesives offer strong bonding properties and fast curing times. They are commonly used in signage, automotive, and manufacturing sectors.

- Silicone Adhesives: Known for their temperature resistance and flexibility, silicone adhesives are ideal for high-temperature and waterproof applications, particularly in the automotive and construction industries.

- Hot Melt Adhesives:Hot melt adhesives are applied in molten form and solidify on cooling. They are used in packaging, labeling, and product assembly and offer quick adhesion and high-speed application.

Each type of adhesive is tailored to meet the specific needs of different industries, providing manufacturers with a broad range of options.

Key Applications of Industrial Adhesives

Industrial adhesives play a critical role in numerous sectors, including:

- Automotive Industry:Adhesives are crucial for structural and aesthetic purposes in the automotive sector, where they bond parts such as windshields, trim, and internal components.

- Electronics Manufacturing:From PCB assembly to smartphone screens, industrial adhesives ensure components remain securely attached to various electronic devices.

- Construction:Adhesives bond materials such as tiles, windows, insulation, and flooring. They often need to meet high durability and environmental resistance standards.

- Packaging:Adhesives are essential for securing products, ensuring their safety during transportation, and maintaining packaging integrity.

- Aerospace:Adhesives used in the aerospace industry must meet stringent performance requirements, including resistance to extreme temperatures, pressure, and environmental factors.

Industrial Adhesive Solutions Manufacturers: Who Are They?

Industrial adhesive solutions manufacturers produce the specialized adhesives used in these diverse applications. The demand for advanced adhesive products has led to the growth of a competitive market, with manufacturers continuously innovating to meet industries’ changing needs.

Leading Players in the Adhesive Industry

Several global players dominate the industrial adhesive market. These manufacturers have made significant advancements in adhesive technologies, contributing to the expansion of various industries. Some of the leading manufacturers include:

- Henkel AG & Co. KGaA:Henkel is one of the most well-known names in the adhesive industry. It provides solutions for automotive, electronics, construction, and consumer goods and is known for its extensive research and development efforts to produce high-performance adhesives.

- 3M:Known for its innovation and extensive portfolio, 3M provides various adhesives for different industries, including automotive, electronics, medical, and industrial manufacturing.

- B. Fuller:H.B. Fuller manufactures industrial adhesives for industries such as packaging, construction, electronics, and automotive. Their adhesives are known for their strong bonding capabilities and sustainable options.

- Sika AG:Sika produces adhesives for construction, automotive, and industrial applications. Their products are renowned for their durability and environmental resistance.

- BASF:BASF, a global chemical giant, produces industrial adhesives in the automotive, construction, electronics, and packaging industries. It emphasizes sustainable products.

Small and Medium-Sized Manufacturers

While large global players dominate the market, several smaller, specialized manufacturers focus on specific niche markets. These companies often produce high-performance, custom adhesives tailored to specific industrial applications.

- Permabond:A leading manufacturer of adhesives used in engineering and industrial applications, Permabond offers solutions for bonding plastics, metals, and ceramics.

- Lord Corporation:Known for its expertise in adhesives for automotive and aerospace industries, Lord Corporation specializes in structural adhesives that can withstand extreme conditions.

- Master Bond:A manufacturer of high-performance adhesives for industries such as electronics, aerospace, and medical devices, Master Bond offers custom solutions tailored to specific needs.

Trends Shaping the Future of Industrial Adhesive Solutions

The industrial adhesive market continuously evolves, with manufacturers focusing on innovation to address new challenges and opportunities. Some of the key trends shaping the future of the industry include:

Sustainability and Eco-Friendly Adhesives

- As industries face increasing pressure to adopt environmentally friendly practices, industrial adhesive solutions manufacturers are focusing on developing sustainable products. This includes creating adhesives with low volatile organic compounds (VOCs), recyclable packaging, and bio-based raw materials. Many manufacturers also invest in developing safe adhesives for workers and the environment.

Smart Adhesives and Nanotechnology

- The incorporation of nanotechnology into adhesives is gaining momentum. Nanomaterials can enhance the properties of adhesives, such as improving their strength, flexibility, and resistance to heat and chemicals. Innovative adhesives, which can change their properties in response to external stimuli, are also being developed for advanced healthcare, electronics, and robotics applications.

Automation and Robotics

- The increased adoption of automation and robotics in manufacturing processes has created a demand for adhesives that can be applied quickly and efficiently in automated environments. Manufacturers focus on producing adhesives that work well with robotic systems and can bond substrates at high speeds, reducing cycle times and increasing productivity.

Growth in Emerging Markets

- The demand for industrial adhesives is growing in emerging markets such as Asia-Pacific, Latin America, and the Middle East. As industries in these regions expand, there is an increasing need for high-quality adhesive solutions for the automotive, construction, electronics, and packaging sectors. Manufacturers are looking to tap into these growing markets with region-specific products.

Choosing the Right Industrial Adhesive Solution

When selecting an industrial adhesive solution, manufacturers must consider several factors to ensure the product is suitable for their specific application. Here are some key points to consider:

- Application Requirements:Consider the specific bonding requirements, such as strength, flexibility, and resistance to environmental factors like temperature, moisture, and chemicals.

- Material Compatibility:Ensure the adhesive is compatible with the materials being bonded, whether it’s metal, plastic, glass, or other substrates.

- Curing Time:Evaluate the adhesive’s curing time to ensure it aligns with production timelines.

- Sustainability:Opt for adhesives with low environmental impact, including low VOCs and eco-friendly packaging.

- Cost and Performance:Balance cost and performance to ensure the adhesive meets quality and budget requirements.

Conclusion

Industrial adhesive solutions manufacturers are essential in providing industries with the right tools to bond materials securely and efficiently. From producing high-strength epoxy adhesives to developing eco-friendly alternatives, these manufacturers drive innovation that impacts various sectors, including automotive, construction, electronics, and aerospace. As industries continue to evolve, the demand for specialized adhesive solutions will only grow, and manufacturers must adapt to meet the market’s changing needs.

For more about a complete guide to exploring industrial adhesive solutions manufacturers: innovators behind stronger bonds, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.