Epoxy Adhesives Manufacturers: Providing Durable and Versatile Bonding Solutions

Epoxy Adhesives Manufacturers: Providing Durable and Versatile Bonding Solutions

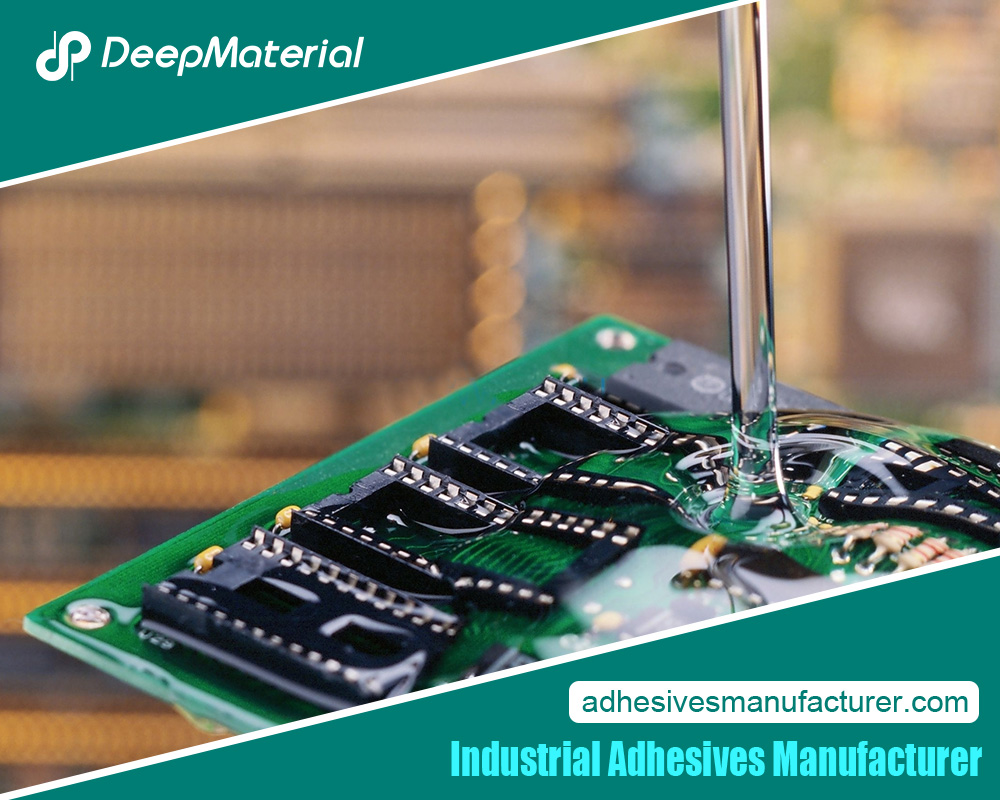

Epoxy adhesives have become essential in various industries, from aerospace and automotive to construction and electronics. These high-performance adhesives offer superior bonding strength, chemical resistance, and durability, making them a preferred choice for numerous applications.

This article will explore the critical aspects of epoxy adhesive manufacturers and their role in meeting the growing demand for these versatile bonding solutions. Epoxy adhesives are composed of two main components: a resin and a hardener. When mixed, these components undergo a chemical reaction that results in a robust and cross-linked polymer.

This curing process allows the adhesive to harden and form a durable bond between the joined materials. Epoxy adhesives are known for their excellent adhesion to various substrates, including metals, plastics, composites, and glass.

Critical Capabilities of Epoxy Adhesives Manufacturers

Epoxy adhesives manufacturers have developed a wide range of products to cater to the diverse needs of their customers. Some of the critical capabilities of these manufacturers include:

Customization and Formulation

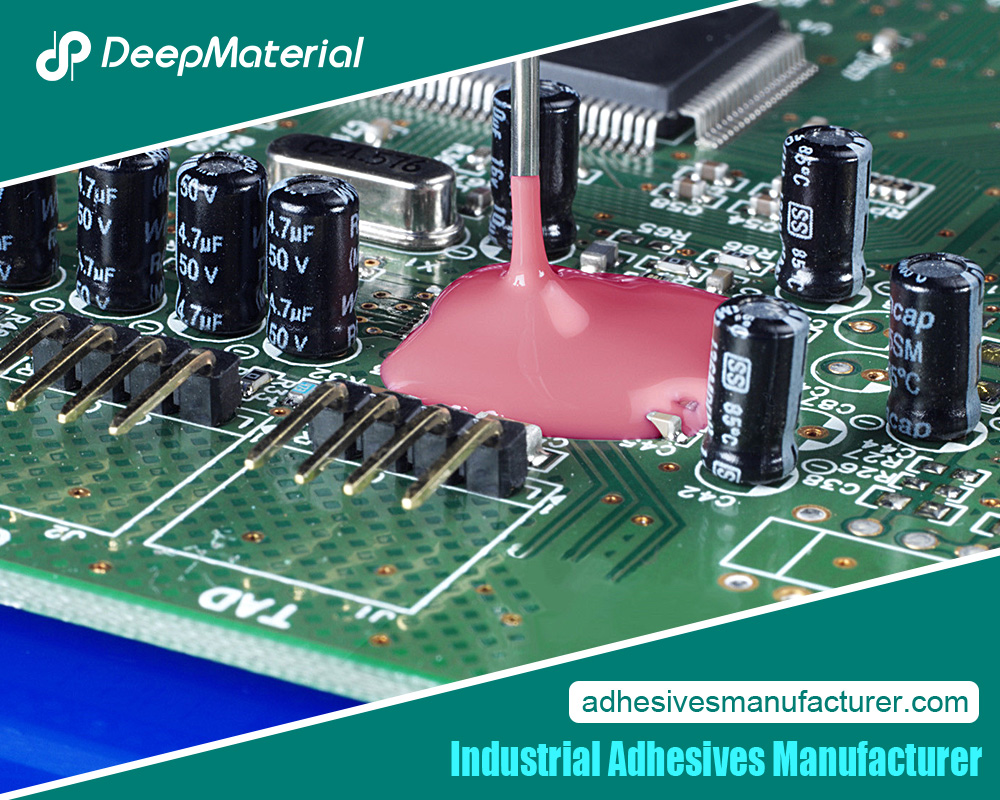

Epoxy adhesive manufacturers often offer customized formulations to meet their clients’ specific requirements. This includes adjusting the adhesive’s viscosity, curing time, and other properties to suit the application. These manufacturers can develop tailored solutions that optimize performance and efficiency by working closely with their customers.

High-Performance Bonding

Epoxy adhesives are renowned for their exceptional bonding strength, which can exceed the tensile strength of the joined materials. Manufacturers have developed advanced formulations that can withstand high temperatures, harsh chemicals, and other challenging environmental conditions, making them suitable for demanding applications.

Versatility and Compatibility

Epoxy adhesives can bond a wide range of materials, including metals, plastics, composites, and ceramics. Manufacturers have formulated products that are compatible with various substrates, allowing for the creation of durable and reliable bonds in various industries.

Regulatory Compliance

Many epoxy adhesive manufacturers have obtained certifications and approvals from regulatory bodies, such as the International Organization for Standardization (ISO) and industry-specific organizations. This ensures their products meet stringent quality and safety standards, making them suitable for use in regulated industries like aerospace, automotive, and medical.

Key Players in the Epoxy Adhesives Manufacturing Industry

Both large multinational corporations and smaller, specialized companies populate the epoxy adhesives manufacturing industry. Some of the key players in this market include:

- 3M Company

- Henkel AG & Co. KGaA

- Huntsman Corporation

- Sika AG

- Dow Inc.

- Momentive Performance Materials Inc.

- Permabond Engineering Adhesives

- LORD Corporation

- Bostik (Arkema Group)

- Ashland Global Holdings Inc.

These manufacturers offer a diverse range of epoxy adhesive products for various industries and applications. They continuously invest in research and development to enhance their offerings’ performance, durability, and sustainability.

Market Trends and Drivers

The global epoxy adhesives market is expected to experience significant growth in the coming years, driven by several key factors:

- Increasing Demand from the Aerospace and Automotive Industries

- Growing Adoption in Construction and Infrastructure Projects

- Rising Popularity of Lightweight and Composite Materials

- Advancements in Epoxy Adhesive Formulations

- Stringent Environmental Regulations and Sustainability Concerns

Manufacturers are responding to these market trends by developing innovative epoxy adhesive solutions that address their customers’ evolving needs. This includes introducing eco-friendly, low-VOC (volatile organic compound) formulations and products with enhanced thermal and electrical properties.

What Are The Advantages And Disadvantages Of Using Epoxy Adhesives?

Based on the search results, the key advantages and disadvantages of using epoxy adhesives are:

Advantages of Epoxy Adhesives:

- High Bonding Strength: Epoxy adhesives provide excellent bonding strength, allowing for strong and durable bonds between various materials. They can withstand high loads, stresses, and vibrations.

- Versatility: Epoxy adhesives can bond with various materials, including metals, composites, plastics, ceramics, and more, making them suitable for diverse applications.

- Chemical and Environmental Resistance: Epoxy adhesives are resistant to chemicals, solvents, moisture, heat, and other environmental factors, ensuring the longevity and reliability of the bonded structure.

- Gap Filling Capabilities: Epoxy adhesives can fill gaps and irregularities between mating surfaces, compensating for imperfections and enhancing the assembly’s overall strength and integrity.

- Excellent Adhesion: Epoxy adhesives exhibit strong adhesion to various substrates, creating a durable bond resistant to peeling, cracking, or delamination.

Disadvantages of Epoxy Adhesives:

- Cure Time: Epoxy adhesives typically require a curing process that can take several hours or even days, slowing down production or assembly processes.

- Mixing and Application: Epoxy adhesives require proper mixing of resin and hardener components before application, which can be complex and messy.

- Health and Safety Precautions: Some epoxy adhesives may contain chemicals that can be hazardous if not handled properly, requiring users to follow safety guidelines.

- Cost: Epoxy adhesives can be more expensive than other adhesives, which may not be suitable for applications with budget constraints.

- Brittleness: When not toughened, the cured epoxy adhesive can be generally brittle, with poor peeling, crack, and impact resistance.

Epoxy adhesives’ key advantages are their high bonding strength, versatility, chemical and environmental resistance, gap-filling capabilities, and excellent adhesion. The main disadvantages are:

- The long cure time.

- Complex mixing and application.

- Health and safety concerns.

- Higher cost.

- Potential brittleness of the cured product.

What Are The Safety Precautions When Using Epoxy Adhesives?

Several safety precautions are crucial when using epoxy adhesives to ensure a safe and healthy working environment. These precautions include:

- Proper Ventilation: Work in a well-ventilated area to prevent the buildup of fumes and vapors released during curing. This is especially important when working with epoxy adhesives in confined spaces or areas with poor air circulation.

- Personal Protective Equipment (PPE): Wear appropriate PPE, such as gloves, safety glasses, and a mask, to protect your skin and respiratory system from direct contact with the resin and any airborne particles.

- Skin Protection: Wear gloves that can withstand the chemicals within epoxy resin, such as nitrile or vinyl, and consider wearing coveralls and long sleeves to prevent skin contact. If skin contact occurs, wash the affected area thoroughly with soap and water.

- Eye Protection: Use safety goggles or glasses to protect your eyes from accidental splashes or exposure to resin fumes.

- Avoid Skin Contact: Minimize skin contact with epoxy resin, as prolonged exposure may irritate. If skin contact occurs, wash the affected area thoroughly with soap and water.

- Follow Instructions: Always follow the manufacturer’s instructions and recommended safety precautions when using epoxy adhesives. Different formulations may have specific guidelines that should be followed.

- Proper Storage: Ensure the safe storage of epoxy adhesives, especially in households with children. Store them in a secure, designated area that is out of reach of children, and avoid storing them in common areas where children may have easy access.

- Handling and Disposal: Handle epoxy adhesives carefully, avoiding spills and splashes. Dispose of any contaminated materials and wash your hands thoroughly after handling epoxy adhesives.

- Training and Supervision: Provide workers with training and supervision on the proper handling and use of epoxy adhesives, emphasizing the importance of following safety guidelines and precautions.

- Monitoring and Maintenance: Regularly monitor and maintain the working environment to ensure it remains safe and healthy. This includes ensuring proper ventilation, maintaining equipment, and addressing potential hazards.

Following these safety precautions can minimize the risks of using epoxy adhesives and ensure a safe and healthy working environment.

Conclusion

Conclusion

Epoxy adhesives manufacturers are crucial in providing durable and versatile bonding solutions to various industries. By leveraging their expertise in customization, high-performance bonding, and regulatory compliance, these manufacturers are well-positioned to meet the growing demand for advanced adhesive technologies. As the market continues to evolve, epoxy adhesive manufacturers will likely focus on developing sustainable, high-performance products that cater to the ever-changing needs of their customers.

For more about the epoxy adhesives manufacturers: providing durable and versatile bonding solutions, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.