Connecting the Future: Trusted Industrial Electronic Component Adhesive Suppliers

Connecting the Future: Trusted Industrial Electronic Component Adhesive Suppliers

Industrial electronic component adhesive suppliers play a crucial role in the manufacturing industry. These suppliers provide the adhesives that are used in the production of electronic components, ensuring that they are securely and reliably bonded together. The quality and reliability of these adhesives are of utmost importance, as they directly impact the performance and longevity of the electronic components.

In order to ensure the highest quality adhesives, it is essential for manufacturers to build strong relationships with trusted suppliers. Trust is the foundation of these relationships, as it ensures that the suppliers will consistently deliver high-quality adhesives that meet the manufacturers’ requirements.

The Importance of Trust in Industrial Electronic Component Adhesive Suppliers

The Importance of Trust in Industrial Electronic Component Adhesive Suppliers

Trust is crucial in supplier relationships, especially when it comes to industrial electronic component adhesive suppliers. Manufacturers rely on these suppliers to consistently provide high-quality adhesives that meet their specifications.

Without trust, manufacturers run the risk of receiving subpar adhesives that can lead to product failures and costly rework. Trust also plays a role in the reliability of delivery. Manufacturers need to be confident that their adhesive suppliers will deliver their orders on time and in the quantities requested.

Furthermore, trust is essential in ensuring the quality and reliability of the adhesives used in manufacturing. Manufacturers need to have confidence that the adhesives they are using will bond the electronic components securely and reliably.

This is especially important in industries where the electronic components are subjected to harsh environments or extreme conditions. Trust in the adhesive supplier’s expertise and quality control processes is crucial in ensuring that the adhesives will perform as expected.

Factors to Consider When Choosing a Trusted Industrial Electronic Component Adhesive Supplier

When choosing a trusted industrial electronic component adhesive supplier, there are several factors that manufacturers should consider. These factors include the quality of the adhesives, the reliability of delivery, customer service and support, and price and value.

The quality of the adhesives is of utmost importance. Manufacturers should ensure that the adhesive supplier has a robust quality control process in place to ensure that the adhesives meet their specifications. This can include testing the adhesives for strength, durability, and resistance to environmental factors. Manufacturers should also consider the supplier’s track record and reputation in the industry.

Reliability of delivery is another important factor to consider. Manufacturers need to be confident that their adhesive supplier will deliver their orders on time and in the quantities requested. Delays in delivery can disrupt production schedules and lead to costly downtime. Manufacturers should inquire about the supplier’s delivery capabilities and their track record in meeting delivery deadlines.

Customer service and support are also crucial factors to consider. Manufacturers should choose a supplier that is responsive and provides excellent customer service. This includes being available to answer any questions or concerns, providing technical support when needed, and offering assistance in selecting the right adhesive for specific applications.

Price and value are also important considerations. While price is certainly a factor, manufacturers should not solely focus on finding the lowest cost supplier. It is important to consider the overall value that the supplier provides, including the quality of their adhesives, reliability of delivery, and customer service. Choosing a supplier based solely on price can lead to subpar adhesives and costly rework in the long run.

Benefits of Using Trusted Industrial Electronic Component Adhesive Suppliers

Using trusted industrial electronic component adhesive suppliers can provide several benefits to manufacturers. Firstly, it can lead to improved product quality and reliability. Trusted suppliers are more likely to provide high-quality adhesives that meet the manufacturers’ specifications. This can result in electronic components that are more durable and reliable, reducing the risk of product failures and costly rework.

Secondly, using trusted suppliers can help reduce downtime and maintenance costs. By using high-quality adhesives, manufacturers can minimize the risk of bond failures and the need for repairs or replacements. This can result in increased uptime and productivity, as well as reduced maintenance costs.

Lastly, using trusted suppliers can increase efficiency and productivity. Manufacturers can rely on their adhesive suppliers to consistently deliver high-quality adhesives on time and in the quantities requested. This allows manufacturers to streamline their production processes and reduce the need for inventory management.

Innovations in Industrial Electronic Component Adhesive Technology

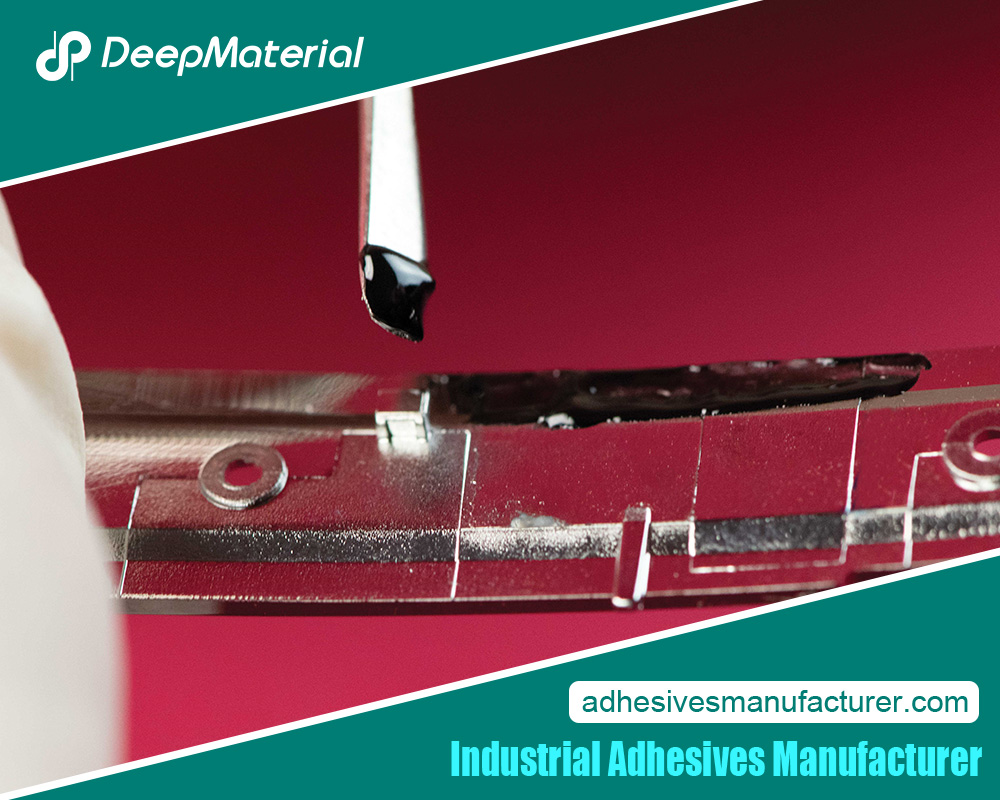

In order to meet the challenges faced by the industry, industrial electronic component adhesive suppliers are constantly innovating and developing new technologies. One area of innovation is in the development of new adhesive materials and formulations. Suppliers are investing in research and development to create adhesives that have improved strength, durability, and resistance to environmental factors. They are also developing adhesives that can bond dissimilar materials together, allowing for more flexibility in design.

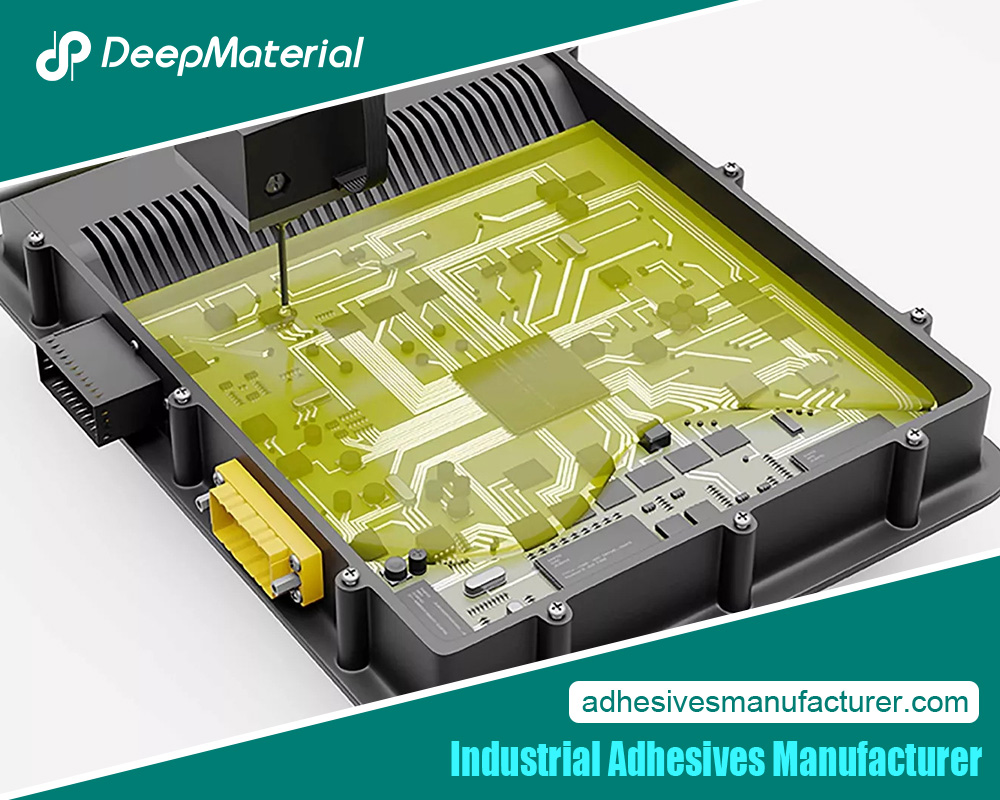

Advancements in application methods and equipment are also driving innovation in the industry. Suppliers are developing new application methods and equipment that allow for more precise and efficient bonding. This includes automated dispensing systems that can accurately apply adhesives in complex patterns, as well as curing systems that can rapidly cure adhesives without the need for heat or pressure.

Future Trends in Industrial Electronic Component Adhesive Suppliers

Looking ahead, there are several future trends that are expected to shape the industry of industrial electronic component adhesive suppliers. One trend is an increased focus on sustainability and environmental impact. Manufacturers and consumers are becoming more conscious of the environmental impact of their products and are demanding more sustainable solutions. Adhesive suppliers are investing in research and development to develop adhesives that are more environmentally friendly, such as bio-based adhesives or adhesives with reduced volatile organic compounds (VOCs).

Another future trend is the greater use of automation and robotics in manufacturing. As technology advances, manufacturers are increasingly turning to automation and robotics to improve efficiency and productivity. Adhesive suppliers need to adapt to these changes by developing adhesives that can be easily integrated into automated manufacturing processes. This includes developing adhesives that can be dispensed by robotic systems and cured using automated curing systems.

Lastly, there is a growing demand for customized adhesives and solutions. Manufacturers are seeking adhesives that are tailored to their specific needs and requirements. Adhesive suppliers need to be flexible and responsive to these demands, offering customized solutions that meet the unique needs of their customers.

Final Words

Final Words

Building strong relationships with trusted industrial electronic component adhesive suppliers is crucial for manufacturers in the industry. Trust is the foundation of these relationships, as it ensures that the suppliers will consistently deliver high-quality adhesives that meet the manufacturers’ requirements. By choosing trusted suppliers, manufacturers can benefit from improved product quality and reliability, reduced downtime and maintenance costs, and increased efficiency and productivity.

For more about a complete guide to the Trusted Industrial Electronic Component Adhesive Suppliers, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.