Apply nonconductive coating for electronics to improve efficiency

Apply nonconductive coating for electronics to improve efficiency

Electronics has become an integral part of major industries and daily use products. The heavy reliance on electronic products has pressed upon the need for utmost efficiency from these devices. Efficiency is critical for reliable device usage in many industries such as industrial equipment, consumer devices, and aerospace systems. We sometimes get so invested in the performance of the electronics that we overlook major aspects like efficiency and reliability. But electronics industry has seen a huge shift towards efforts to enhance efficiency. The industry is inclined towards nonconductive coating for electronics as a means to enhance their useful life and efficient usage. The usage of nonconductive coating for electronics to enhance efficiency has become a new trend in the electronics world. If you are not familiar with this trend then it is alright because it is still booming. This article will serve as your guide to see the advantages and efficiency that you can enjoy by applying these coatings.

Let us start this comprehensive guide into nonconductive coatings by first understanding what these coatings are.

Let us start this comprehensive guide into nonconductive coatings by first understanding what these coatings are.

What are nonconductive coatings?

Nonconductive coatings are specialized types of coatings that block the flow of electrons inside the electrical circuit and also from any external source. These coatings also act as a barrier against the flow of heat. They shield the emission of heat and electrons flow from metal substrates.

As the name suggests, nonconductive coatings are made with nonconductive materials. These are usually formulated with organic substances. Their inherent insulated properties help them to naturally act as a barrier against conductive flow between metals and the environment. They naturally lack traces of metals including zinc, copper, and nickel which is why they are genuinely unable to conduct electricity.

Major groups of Nonconductive coating for electronics include epoxies, ceramics, polymers, and polyurethanes. Nonconductive coatings are also known as insulation coating, insulative coatings, and insulating coatings. So, don’t get confused if you find different industrialists using different names.

Nonconductive coating for electronics acts as a protective shield for electronic components and protects them from electric conductivity by isolating the conductive compounds and keeping them apart whether they are confined in a circuitry or are outside the electronic device.

Why apply nonconductive coating for electronics to improve efficiency?

Here are the major features, uses, and benefits of applying a nonconductive coating for electronics that will show you how these coatings are improving the efficiency of electronic devices:

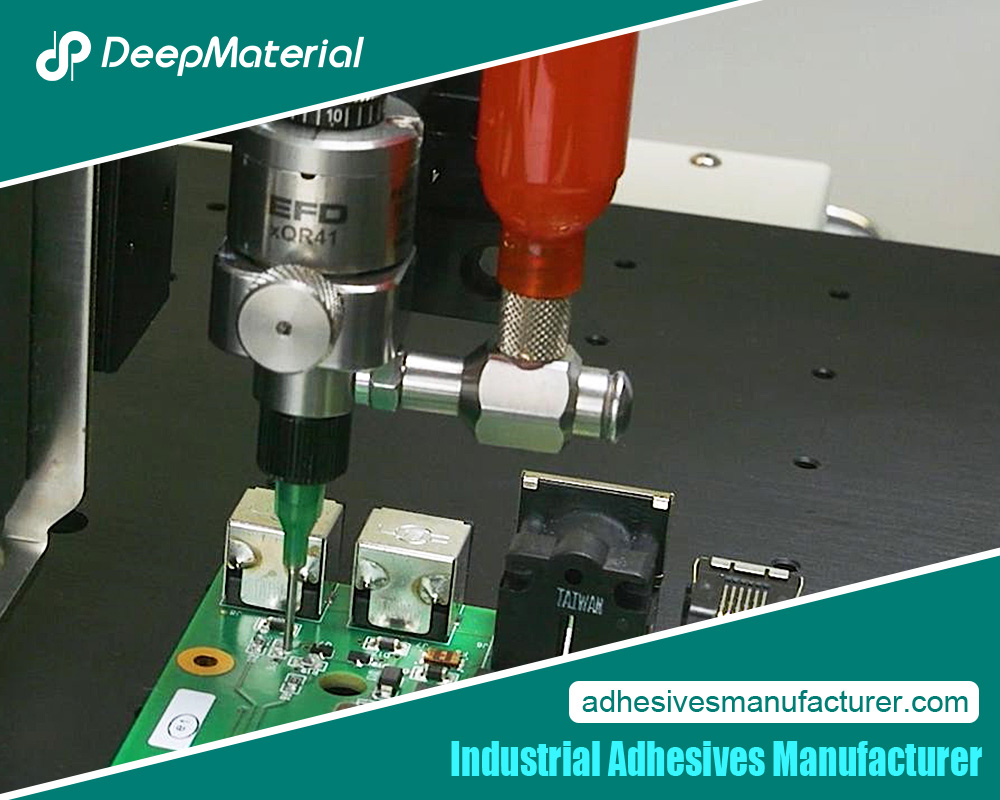

- An essential part of PCBs: Nonconductice coatings are an essential part of printed circuit boards. Electrical circuits and components are strategically placed on the PCB. This systematic and strategic location is necessary to get the desired results from the circuit board. To achieve the desired results efficiently, it is a prerequisite to insulate the electric components to ensure that the current does not flow where it is not intended.

- Bond electronic components on PCB: the electronic components are usually mounted on the PCB. But you need to be careful because there are current paths meant for the desired flow of current. If these components are mounted with a conductive adhesive then they can pick up that current flow and end up in electrical interference. This is why for efficient working of PCB, it is necessary to mount the components with a nonconductive coating for electronics.

- Insulation against heat: along with insulating electric conductivity, the nonconductive coating for electronics also helps in providing insulation against heat. Heat emissions can be harmful to electronic components and circuits. It is impossible to stop the heat emission so we have to come up with a strategy to make sure that this heat emission doesn’t overheat the electric device so that it malfunctions or gets damaged. Nonconductive coating for electronics works as a life-saving coating in such situations which tone down the heat and prevents its access to sensitive electronic components. The application of nonconductive coatings works as a shield against excessive heat that can be harmful to the electronic device and its components and ensures that the device functions efficiently even in the presence of heat emission.

- Shield against electromagnetic interference: Electromagnetic interference can be hazardous for electric components and the efficient operation of electronic devices. It can degrade their performance by disrupting the current flow in an unintended direction. Nonconductive coating for electronics can act as a strong shield against electromagnetic interference by efficiently blocking their signals. By offering a safeguard shield, these coatings can protect the sensitive components and divert the impact of electromagnetic interference. It helps to maintain the structural integrity of electronic systems, especially in industries that are exposed to electromagnetic noise.

- Preventing corrosion: Nonconductive coating for electronicsoffers more than just insulation against heat and electric flow. They can serve to protect a strong shield against corrosion that can be a damaging force for metals. When you apply a Nonconductive coating for electronics to metal substrates then it turns into an inert material that resists moisture ingress from the atmosphere. It protects the metals against corrosion which in turn extends their useful life and ensures that they function optimally as required.

- Protection against environmental impact: environmental factors can also impact the working of electronic devices. Certain factors can work as a deteriorating force against the efficient working of electronics such as temperature variation, physical impact, and moisture. Nonconductive coating for electronics protects the electronic devices and components from the adverse impact of these environmental factors. By offering powerful insulation againt heat and moisture, these coatings safeguard the delicate circuitry from thermal variations and moisture ingress. In addition, the adhesion of components through insulated coating ensures that there is no risk of electrical interference when subject to any physical impact.

- Exceptional dielectric strength: Nonconductive coating for electronics offers exceptional dielectric properties. These properties enable them to prevent any possible voltage leakage between the electronic components by enhancing the level of insulation between them. The dielectric strength also helps minimize the possible risk of electrical breakdown and short circuits. It not only improves the reliability of electronic systems but also enhances the safety of electronic devices. The application of nonconductive coatings is especially essential in high-voltage industries where electrical insulation is critical.

For more about a complete guide to apply nonconductive coating for electronics to improve efficiency, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.