An A – Z guide to an anaerobic adhesives and sealants manufacturer

There are some specific engineering applications that usually require special gels to produce tight seals. An anaerobic adhesives and sealants manufacturer know the right solution to use as a threadlocker in industrial environments. There are many industrial applications that need medium to high strength gels to produce tight sealing and fastening solutions for durable performance. Naturally, they also need special activators and curing methods to reach their maximum potential.

What are anaerobic adhesives

These are engineered adhesives that are made to cure easily without air. Anaerobic adhesives have special properties that make them highly useful for industrial applications. They have less toxicity and do not have offensive odors. As mild adhesives, they do not corrode metals. These adhesives have special storage conditions that means that a significant part of the surface is exposed to air. Due to the special nature of these bonding agents, an anaerobic adhesives and sealants manufacturer can produce the glue in several viscosity. They are applied in specific cases when it comes to filling bonding spaces of between 0.001 and 0.04 inches.

Application of anaerobic adhesives

When it comes to the application of anaerobic adhesives, they are used ideally on structural bonds. When it comes to the right materials of application, the adhesives can be applied onto glass, metals, wood, plastics, and other types of substrates. On application of the anaerobic glue, there is usually an accompanying activator. The activator can be applied onto one or both substrates to be bonded. After applying the activator, the next stage is to apply the adhesive on one of the surfaces. Anaerobic adhesives usually produce joints that can resist organic solvents and moisture. These joints are also made to be resistant to temperature and weather.

Curing with anaerobic adhesives

With anaerobic adhesives, the process of curing begins as soon as you apply the adhesive. The speed of the curing process depends on the type of activators used on the adhesive. Adhesive and sealants manufacturers usually have a wide range of activators to go with several anaerobic bonding solutions. When it comes to the curing time, it takes from under 30 seconds to over 30 minutes. When it comes to curing anaerobic adhesives, you can choose to apply heat in addition to or instead of the activators.

The use of activators with anaerobic adhesives

An anaerobic adhesives and sealants manufacturer will usually produce an activator to go with their anaerobic bonding solution. Activators are specially engineered catalysts that are used alongside the adhesive. In practical conditions, these activators are unique complimentary chemicals that are applied before the adhesive is introduced. They are catalysts that are used to improve the adhesive quality of the anaerobic bonding solution. Activators are usually applied in several typical cases where this anaerobic adhesives are used. Activators are also called initiators. According to adhesive manufacturers, there are numerous available activators that can be used to cure many industrial adhesives.

Primers and accelerators with anaerobic adhesives

When it comes to the application of anaerobic adhesives, primers and accelerators are used to improve the process. Primers are used to enhance the surface properties of the material. This way, the adhesive will adhere properly on it. When a primer is used in the application of adhesives, it can be used to increase its ability to properly wet the surface. Adhesives have special primers that helps to enhance the material surface. This primer is usually applied before applying the adhesive. Primers are neither accelerators or activators. They are not applied to increase the cure speed of the adhesive. An accelerator is used with adhesives in order to accelerate the total cure time. However, this compound may usually compromise the strength of the bond formed. If you are bonding an anaerobic cyanoacrylate to a porous material, this usually requires the use of an accelerator. Whenever the accelerator is added to the substrate, it can simply improve the its adhesive properties. It works to increase the cure before the substrates is able to absorb this adhesive totally.

Conditioning an anaerobic surface

Anaerobic adhesives require the presence of certain catalysts to cure. In this, only metal ions help anaerobic adhesives to cure out fully. However, some materials used in the reaction tend to react more in comparison with others. Anaerobic adhesives are specially designed surface conditioners. This helps to increase the curing process. However, these conditioners are known to reduce the strength produced by the bonds.

Production of anaerobic adhesives

Anaerobic adhesives are specially engineered bonding solutions that are used in specific industrial applications. An anaerobic adhesives and sealants manufacturer usually blend several elements to produce this unique bonding solution. This type of adhesive usually cures better when oxygen (air) is not present. In the absence of oxygen, the molten anaerobic adhesive usually polymerizes to form a strong and hard solid. The base element is used to produce anaerobic adhesives is TEGDMA (triethylene glycol dimethacrylate). Just like every other available adhesives, manufacturers usually produce this type of adhesive using various catalysts and components. While the production process can be difficult, the varying catalyst and ingredients makes the final bonding solution work satisfactorily. Much of the production processes that goes into manufacturing specific anaerobic adhesives are commercial secrets. Therefore, they may not be readily available in the public domain.

Primary applications of anaerobic adhesives

Primary applications of anaerobic adhesives

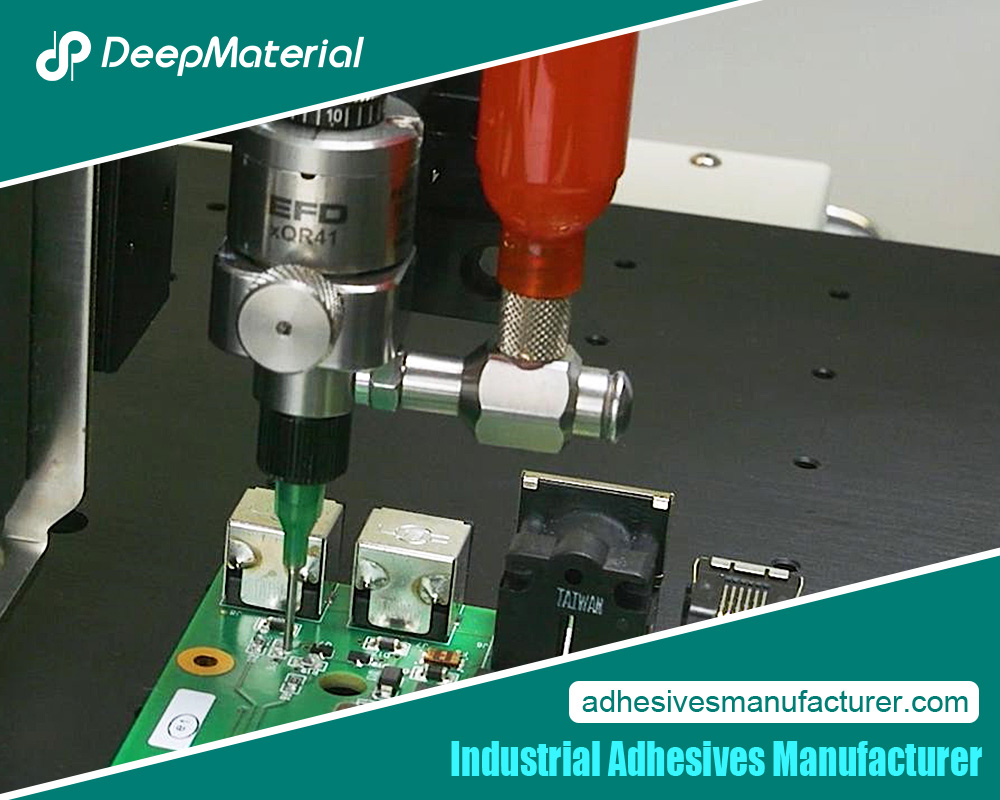

Anaerobic adhesives are manufactured primarily as special engineering bonding solutions. They are used primarily for thread locking in applications where threaded assemblies are involved. In addition, they can also be applied in co-axial joints where they are used for mechanical jamming. Based on the design intentions of anaerobic adhesives and sealants manufacturers, these bonding solutions are only used secondarily as adhesives. As engineered bonding solutions, they have helped many production businesses ans facilities save time and money. As single-part adhesives, they are low-viscosity glues that cure only when applied to metal surfaces and without air. Manufacturers produce the adhesive mainly to be used for locking threaded assemblies. When applied in these situations, they obtain as much torque as you can get with lock-screws and lock-nuts. Pipe fitting industries like construction and mechanical engineering rely on this adhesive for excellent bond performance.

For more about choosing the best adhesive formula for anaerobic adhesives and sealants manufacturer,you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.