Adhesive Manufacturing Companies: A Comprehensive Guide

Adhesive Manufacturing Companies: A Comprehensive Guide

Adhesives are essential in modern industries, binding materials together in applications ranging from household products to complex industrial assemblies. Adhesive manufacturing companies produce vast adhesives that cater to different needs, such as bonding, sealing, insulation, and coating. With technological innovations, the adhesive manufacturing industry has grown significantly, catering to the automotive, aerospace, electronics, construction, healthcare, and packaging sectors. This article provides a comprehensive guide to adhesive manufacturing companies, covering the types of adhesives they produce, industry leaders, market trends, and the challenges they face in today’s competitive landscape.

Types of Adhesives and Their Applications

Adhesives come in many forms, each designed for specific applications and industries. Here’s an overview of the primary types of adhesives produced by manufacturing companies:

Epoxy Adhesives

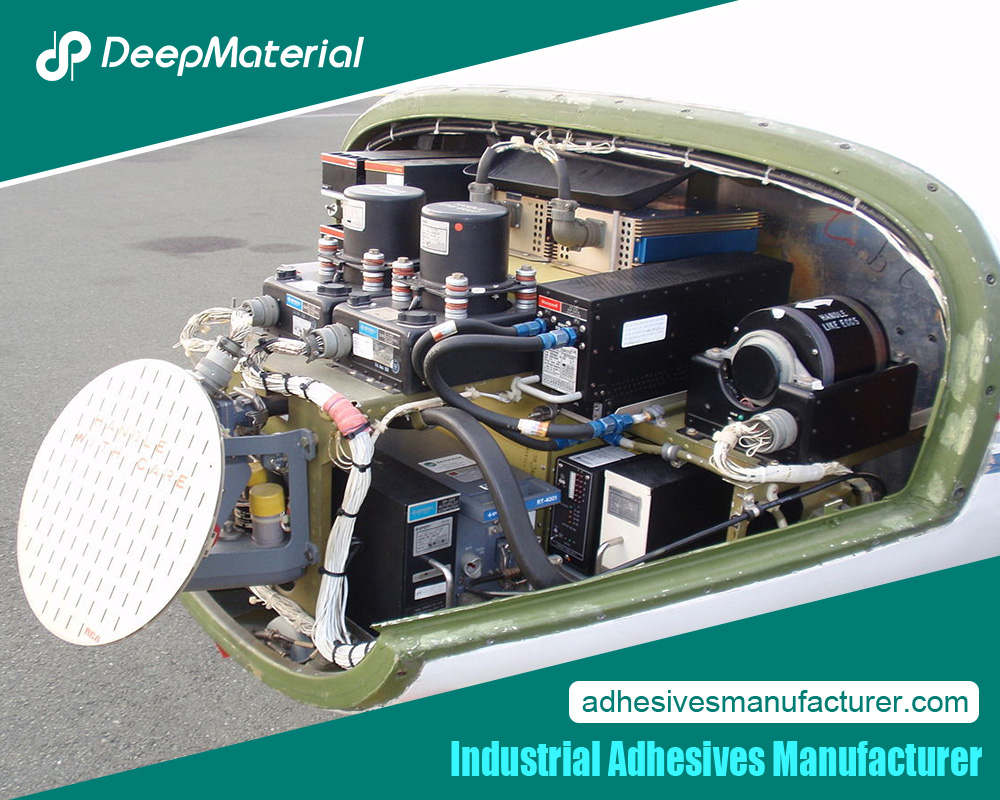

Epoxy adhesives are known for their high strength and resistance to environmental degradation. Due to their durability, they are commonly used in automotive, aerospace, and construction applications. Epoxy adhesives are ideal for bonding metals, plastics, ceramics, and wood, making them a go-to choice for structural applications.

Polyurethane Adhesives

Polyurethane adhesives are versatile, offering strong bonds and flexibility. They are often used in the construction and woodworking industries for bonding materials that may expand or contract over time. Polyurethane adhesives also provide excellent resistance to moisture, making them suitable for outdoor applications.

Acrylic Adhesives

Acrylic adhesives are known for their quick-setting properties and are often used in automotive and medical device assembly. They provide a strong bond even on surfaces with minimal preparation, making them suitable for bonding plastics, metals, and composites.

Silicone Adhesives

Silicone adhesives are highly flexible and resistant to temperature extremes, chemicals, and UV radiation. These adhesives are widely used in electronics, automotive, and construction industries, especially in applications requiring a sealant or bonding material that can withstand harsh environmental conditions.

Hot Melt Adhesives

Due to their fast bonding properties, hot melt adhesives are widely used in packaging, woodworking, and textile industries. They are applied in a molten state and solidify as they cool, providing a strong, durable bond. Hot melt adhesives are commonly used in packaging to seal boxes, bind books, and assemble other items that require fast setting.

Pressure-Sensitive Adhesives (PSAs)

PSAs are used in applications where the adhesive needs to stick upon contact without requiring heat or solvents. These adhesives are commonly found in tapes, labels, and stickers, making them popular in consumer products and industrial applications.

Anaerobic and Cyanoacrylate Adhesives

Anaerobic adhesives cure without oxygen and are ideal for sealing threaded fasteners and components. Cyanoacrylate adhesives, or “superglues,” bond quickly and are suitable for small-scale applications or repairs involving metals, ceramics, and rubber.

Each type of adhesive offers unique properties and is tailored to specific applications, providing the foundation for many industrial processes.

Leading Adhesive Manufacturing Companies

Numerous adhesive manufacturing companies dominate the global market. Here is a closer look at some of the leading companies in the industry:

Henkel AG & Co. KGaA

Headquartered in Germany, Henkel is one of the largest adhesive manufacturers globally. The company’s adhesive technologies are used in the automotive, electronics, and aerospace sectors. Henkel’s brands, such as Loctite and Technomelt, are recognized for their quality and reliability.

3M Company

3M is an American multinational company known for its innovative products, including adhesives and tapes. The company’s adhesives are used in healthcare, electronics, automotive, and construction industries. 3 M’s VHB tapes and Scotch adhesives have set industry standards for performance and durability.

H.B. Fuller Company

H.B. Fuller is a leading adhesive manufacturer based in the United States. It serves industries such as packaging, construction, and electronics. Known for its focus on sustainable and innovative adhesive solutions, H.B. Fuller continues to expand its product range to meet evolving industry demands.

Arkema Group (Bostik)

French-based Arkema Group owns Bostik, a prominent name in the adhesive industry. Bostik specializes in products for construction, automotive, and industrial applications, offering solutions that emphasize environmental responsibility and durability.

Sika AG

Sika AG, headquartered in Switzerland, produces adhesives and sealants for construction and industrial applications. It contributes to green building initiatives and provides adhesives that meet sustainable building standards.

Avery Dennison

Avery Dennison is known for its pressure-sensitive adhesives and labeling solutions. Headquartered in the United States, the company’s products are widely used in the packaging, automotive, and medical industries. Avery Dennison’s commitment to sustainability has led it to develop eco-friendly adhesive solutions.

Dow Chemical Company

Dow Chemical provides various adhesives, primarily serving the automotive, construction, and electronics sectors. Known for its research-driven approach, Dow produces high-performance adhesives that meet the demands of modern industries.

RPM International Inc. (DAP Products)

RPM International owns several brands, including DAP Products, which is widely recognized for its adhesives and sealants in the construction and consumer markets. Home improvement projects commonly use DAP’s caulks, sealants, and adhesives.

These companies have established themselves as leaders in the adhesive industry by investing in research, sustainability, and innovation to meet their customers’ diverse needs.

Market Trends and Innovations in the Adhesive Industry

The adhesive industry has seen several trends that reflect the shifting demands of modern markets. Some of the key trends and innovations include:

Sustainability Initiatives

Manufacturers are developing eco-friendly adhesives that minimize environmental impact as industries focus on sustainability. This includes biodegradable adhesives, solvent-free formulations, and adhesives that are easy to recycle.

Growth in the Automotive Sector

With the rise of electric vehicles (EVs) and lightweight materials, adhesive manufacturers are creating products tailored for automotive applications. These adhesives help bond lightweight components, reduce vehicle weight, and improve fuel efficiency.

Advancements in Medical Adhesives

The healthcare industry requires specialized adhesives for applications like wound care, medical device assembly, and drug delivery systems. Adhesive manufacturers focus on biocompatibility, hypoallergenic formulations, and enhanced adhesion for medical applications.

Smart Adhesives

Innovative adhesives with properties like self-healing and sensing capabilities are being developed for applications in the aerospace and electronics industries. These adhesives are engineered to respond to environmental changes, offering enhanced durability and functionality.

Expansion of Pressure-Sensitive Adhesives (PSAs)

PSAs are gaining popularity due to their versatility and ease of use. Companies are innovating in PSA technology to create more durable and temperature-resistant adhesives suitable for a broader range of applications.

Automation and Efficiency in Manufacturing

With the advent of Industry 4.0, adhesive manufacturing companies are integrating automation into their production processes. Robotics and AI-driven quality control systems enhance manufacturing efficiency, reduce waste, and improve product quality.

Adhesives for Electronics and Wearable Devices

The growing demand for consumer electronics and wearable devices has led to adhesive innovations that bond delicate electronic components. These adhesives are designed to withstand heat and moisture, ensuring the longevity of devices.

Challenges Facing Adhesive Manufacturing Companies

Despite the growth in demand, adhesive manufacturers face several challenges:

Raw Material Costs and Availability

The price and availability of raw materials significantly impact adhesive manufacturers. Many adhesives rely on petrochemicals, and fluctuations in oil prices can influence production costs. The demand for sustainable materials also adds pressure to find eco-friendly raw materials.

Regulatory Compliance

Adhesive manufacturers must adhere to strict regulations regarding volatile organic compounds (VOCs) and other environmental standards. Compliance with global regulations can be challenging, especially for companies operating in multiple countries.

Competition and Innovation Pressure

The adhesive industry is highly competitive, with companies constantly innovating to create superior products. To stay relevant, manufacturers must invest in research and development, which can be costly and time-consuming.

Customer Expectations and Customization

Customers increasingly demand adhesives tailored to specific applications. Customization requires flexibility in manufacturing, which can lead to increased production costs. Meeting these demands while maintaining profitability remains a challenge.

Sustainability Pressures

As more industries seek sustainable solutions, adhesive companies are pressured to produce eco-friendly products. Developing sustainable adhesives that meet performance standards without compromising quality or increasing costs is complex.

The Future of Adhesive Manufacturing

The future of adhesive manufacturing is promising. It will focus on sustainability, innovation, and meeting evolving industry demands. As industries prioritize eco-friendly solutions, adhesive companies will be crucial in providing sustainable products. Advances in material science, robotics, and artificial intelligence will further enable manufacturers to create high-performance adhesives tailored to specific applications, ensuring they remain competitive in a rapidly changing market.

In addition, collaboration between adhesive manufacturers and industries such as automotive, aerospace, and electronics will drive innovations that meet the requirements of emerging technologies. The rise of electric vehicles, renewable energy, and wearable devices presents new opportunities for adhesive manufacturers to develop specialized products that cater to these cutting-edge applications.

Conclusion

Conclusion

Adhesive manufacturing companies are the backbone of modern industries, providing essential products that enable advancements in the healthcare and aerospace sectors. As the demand for specialized, high-performance adhesives grows, manufacturers must navigate challenges like sustainability, regulatory compliance, and fluctuating raw material costs. By focusing on innovation and sustainability, leading adhesive companies are well-positioned to meet future demands and continue contributing to technological progress across industries.

For more about a complete guide to adhesive manufacturing companies: a comprehensive guide, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.