A Comprehensive Guide to Non Conductive Epoxy: Properties, Uses, and Benefits

A Comprehensive Guide to Non Conductive Epoxy: Properties, Uses, and Benefits

Non conductive epoxy is a versatile and reliable material that is used in a wide range of industries and applications. It is important to understand the properties and uses of non-conductive epoxy in order to make informed decisions about its application. This article will provide a comprehensive overview of non-conductive epoxy, including its definition, properties, types, applications, benefits, and safety precautions.

Understanding The Basics of Non Conductive Epoxy

Non-conductive epoxy is a type of epoxy that does not conduct electricity. It is commonly used in applications where electrical insulation is required, such as in the electronics and electrical components industry. Non conductive epoxy differs from other types of epoxy in that it has specific properties that make it suitable for electrical insulation purposes. It is important to understand the unique properties of non-conductive epoxy in order to choose the right type for your application.

Properties of Non Conductive Epoxy: What Makes it Unique?

One of the key properties is its electrical insulation properties. This material possesses a strong ability to resist the flow of electricity, allowing it to endure high levels of voltage without conducting an electrical current. This makes it ideal for use in electrical components and systems where insulation is crucial.

Another important property of non conductive epoxy is its thermal conductivity. It has a low thermal conductivity, which means it does not transfer heat easily. Such property makes it suitable for applications where heat dissipation is important, such as in electronic devices.

Non conductive epoxy also has excellent chemical resistance, which means it can withstand exposure to various chemicals without degrading or losing its properties. This makes it suitable for use in harsh environments where exposure to chemicals is common.

Furthermore, non conductive epoxy has high strength and durability, making it suitable for applications where mechanical strength is required. It can withstand high loads and impacts without breaking or deforming.

Types of Non Conductive Epoxy: Which One is Right for You?

There are different formulations of non-conductive epoxy, each with its own unique properties. Some formulations have higher electrical insulation properties, while others have better thermal conductivity or chemical resistance. It is important to choose the right type of non-conductive epoxy for your specific application.

When choosing, consider factors such as the voltage requirements, temperature range, and chemical exposure of your application. Consult with a supplier or manufacturer to determine the best type of non-conductive epoxy for your needs.

Applications of Non Conductive Epoxy: Where Can it be Used?

It has a wide range of applications across various industries. Some common applications include:

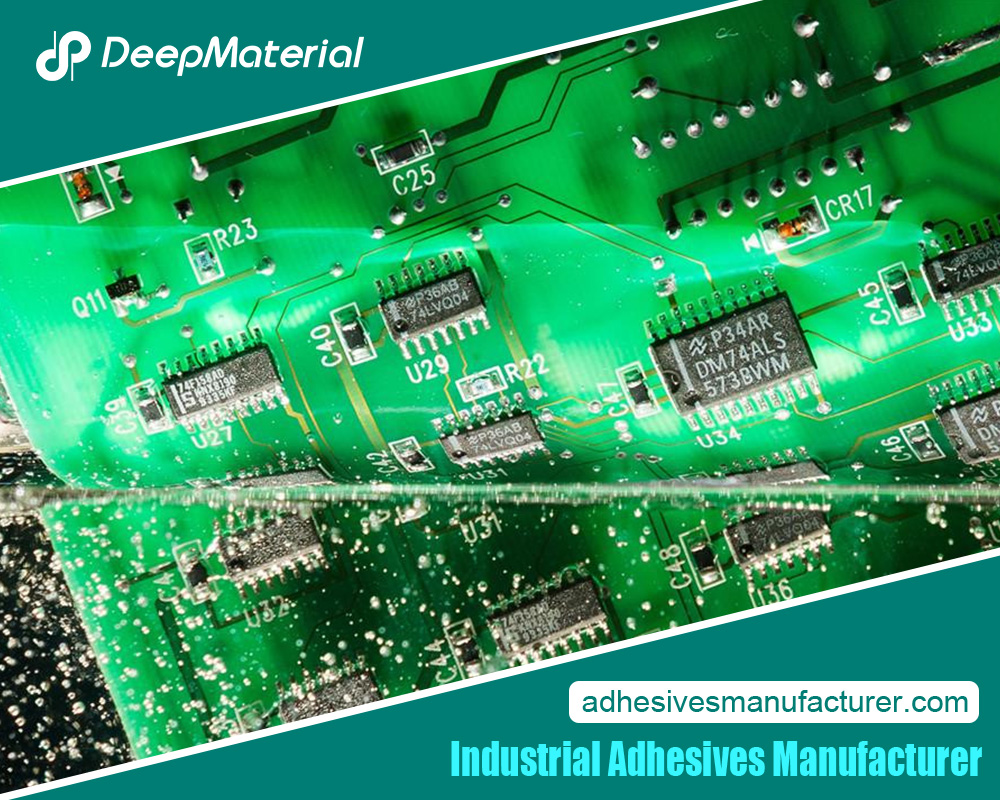

Electronics and electrical components: Non conductive epoxy is used to insulate and protect electronic components, such as circuit boards, transformers, and connectors. It provides electrical insulation and protects against moisture and other environmental factors.

Aerospace and aviation: It is used in the aerospace and aviation industry for applications such as bonding and sealing electrical components, insulating wires and cables, and protecting against electromagnetic interference.

Automotive industry: it is also useful in the automotive industry for applications such as bonding and sealing electrical connectors, insulating wires and cables, and protecting against corrosion.

Construction and infrastructure: It is crucial in the construction and infrastructure industry for applications such as bonding and sealing electrical conduits, insulating wires and cables, and protecting against moisture and other environmental factors.

Marine and underwater applications: It is used in marine and underwater applications for applications such as bonding and sealing electrical connectors, insulating wires and cables, and protecting against corrosion and water ingress.

Benefits of Non-Conductive Epoxy: Why Choose it Over Other Materials?

There are several benefits to using non-conductive epoxy over other materials:

Superior electrical insulation properties: It is known for its excellent electrical insulation properties, making it ideal for applications where electrical insulation is crucial. It can withstand high voltages without conducting electricity, providing a high level of safety and reliability.

High strength and durability: It has high mechanical strength and durability, making it suitable for applications where mechanical strength is required. It can withstand high loads and impacts without breaking or deforming.

Chemical resistance: It has excellent chemical resistance, making it suitable for use in harsh environments where exposure to chemicals is common. It can withstand exposure to various chemicals without degrading or losing its properties.

Versatility and adaptability: It can be formulated to have specific properties to suit different applications. It can be customized to meet the specific requirements of your application, providing a high level of versatility and adaptability.

How to Use Non Conductive Epoxy: A Step-by-Step Guide

Using this adhesive requires proper preparation, mixing, application, and curing. Here is a step-by-step guide on how to use non-conductive epoxy:

Preparation: Clean the surfaces that will be bonded or sealed with non conductive epoxy. Remove any dirt, grease, or other contaminants that may affect the adhesion of the epoxy.

Mixing: Follow the manufacturer’s instructions for mixing the adhesive. Use the recommended ratio of resin to hardener and mix thoroughly until the two components are fully blended.

Application: Apply the mixed epoxy to the surfaces that need to be bonded or sealed. Use a brush, roller, or spatula to spread the epoxy evenly over the surfaces. Make sure to apply enough epoxy to ensure a strong bond or seal.

Curing and drying times: Allow the epoxy to cure and dry according to the manufacturer’s instructions. This may involve leaving the epoxy to cure at room temperature or applying heat to accelerate the curing process. Follow the recommended curing and drying times to ensure proper bonding and sealing.

Last Words

In conclusion, non-conductive epoxy is a versatile and reliable material that is used in a wide range of industries and applications. It has unique properties that make it suitable for electrical insulation purposes, such as high electrical insulation properties, low thermal conductivity, excellent chemical resistance, and high strength and durability.

When using non-conductive epoxy, it is important to choose the right type for your specific application and follow proper handling and safety precautions. By understanding the properties, applications, benefits, and safety precautions of non-conductive epoxy, you can make informed decisions about its use and ensure its effectiveness and longevity.

For more about a complete guide to non conductive epoxy, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/about/ for more info.