A complete guide to industrial adhesive manufacturers and their products

A complete guide to industrial adhesive manufacturers and their products

When it comes to bonding a wide range of materials, product makers usually depend on industrial adhesive manufacturers for all types of solutions. So many product makers usually rely on these adhesive makers to make a wide range of products. This is why industrial adhesive manufacturers have to work to meet the requirements of each customer. These adhesive makers strive to meet the needs of each customer from a different industry. In addition, they also ensure that all their products produce exceptional results.

An Overview on Industrial Adhesives

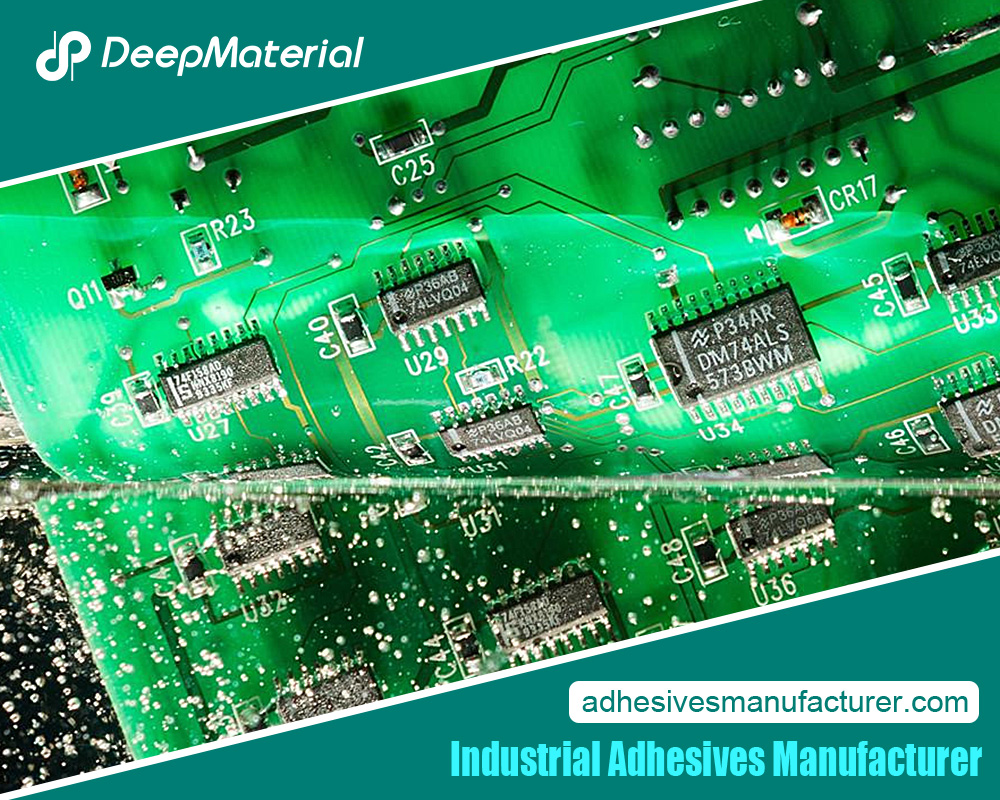

Industrial adhesives are chemically-formulated compounds that are designed and manufactured in industrial environments. These chemicals are used to join all types of components. When it comes to industrial adhesives, manufacturers make a wide range of products that can be used across various industries. These adhesives are made for industries such as electrical/electronics, construction, chemical, manufacturing, haulage and logistics, and so on. Industrial adhesive manufacturers make a wide range of adhesives. Such products include epoxies, acrylics, UV-curing adhesives, hot melt glues, silicones, thermosets, and polyurethane adhesives.

Industrial adhesives versus consumer adhesives

When it comes to making different products for customers, industrial adhesive manufacturers usually specialize in the production of two types of adhesives. These are:

- Industrial adhesives: Industrial adhesive manufacturers help product makers design the right type of adhesives for their production facility. Such adhesives are designed to produce optimal results, improve the quality of product assembly, and minimize manufacturing costs. When it comes to examples of industrial adhesives, manufacturers produce examples such as cyanoacrylates, pressure-sensitive adhesives, hot melt glues, and many more.

- Consumer adhesives: Consumer adhesives are simple adhesives that customers can use in their everyday lives. Such adhesives do not come with any special quality but have exceptional properties like durability, strength, and fast curing. Many generic glues fall into this category. Such adhesives are usually manufactured to be used for everyday applications.

Available types of industrial adhesives

Since industrial adhesives are mainly used in industrial environments, there are several examples of these types of glues. According to industrial adhesive manufacturers, these glues can be classified in different ways. This is either through their adhesive properties or through their chemical ingredients.

Industrial adhesives by adhesive properties

The types of industrial adhesives that are classified in terms of their adhesive behavior include:

- UV curing adhesives: These are special adhesives that depend on UV (ultraviolet) light for curing. Lights can still be produced by other radiation materials. After curing, they create permanent bonds without heating.

- Thermoset adhesives: These are special adhesives that are applied on joints that are expected to withstand great loads. These polymeric resins are usually cured with the application of pressure and heat or only heat.

- PSA (Pressure sensitive adhesives): These are special adhesives that are used for bonding on the application of a slight pressure. These adhesives can be applied easily in areas where clamping may not work. They can also be used on applications that involve big surface areas.

- Hot melt adhesives: These are adhesives that can be melted or softened on application of heat. They can also be made to harden or set by allowing them to cool down. These types of industrial adhesives are easily reworkable. This is because they make it easy for different parts to be placed, removed, and repositioned during the assembly process.

Industrial adhesives by chemical composition

Industrial adhesive manufacturers also produce several glues based on their chemical compositions. These include:

- Acrylic adhesives: These adhesives have excellent environmental resistivity properties. They tend to set faster than other types of industrial adhesives. Examples are super glues or cyanoacrylates which are one-component acrylates that provide instant curing with substrates when they react with surface water.

- Silicone adhesives: These are adhesives and sealants that have high resistance to temperature. They are also known to have great flexibility. Silicone adhesives and sealants are applied in the marine and construction industries.

- Rubber adhesives: These are special industrial adhesives that have very flexible bonds. They are usually created from various industrial rubber-based chemicals.

- Polyurethane adhesives: These are industrial adhesives that offer excellent durability, flexibility, and impact resistance. They are usually applied in woodworking and finish carpentry projects.

- Phenolic, formaldehyde, and melamine resins: These are thermosetting glues that have high-temperature resistance and very strong bonds. Since they are thermoset materials, they usually need heat and pressure or only heat to create very strong bonds when they cure.

- Epoxy adhesives: Epoxy adhesives are chemical compounds that are used to join different components. An epoxy is usually the product of two different chemical products such as a hardener and a resin.

Bonding with industrial adhesives

Industrial adhesives are formulated with very strong chemicals that help to bond a wide range of products. Some of the products that can be glued by industrial adhesives include:

- Metals: Industrial adhesives can help produce easy and seamless bonds when it comes to metals like copper, brass, aluminium, and steel.

- Plastics: Industrial adhesives can be used to bond all types of plastics such as ac4ylics, ABS, PVCs, and so on.

- Wood: Industrial adhesives can be used for the bonding of softwood and hardwood. The furniture industry relies on various industrial adhesives to bond various types of wood.

- Composites: Industrial adhesives can be used to bond composites used in the automotive and aerospace industries. Examples include carbon fibre composites and fibreglass.

- Ceramics: Industrial adhesives can be used to bond various ceramics such as earthenware and porcelain. They help provide secure bonding with ceramic components.

About industrial adhesive manufacturers

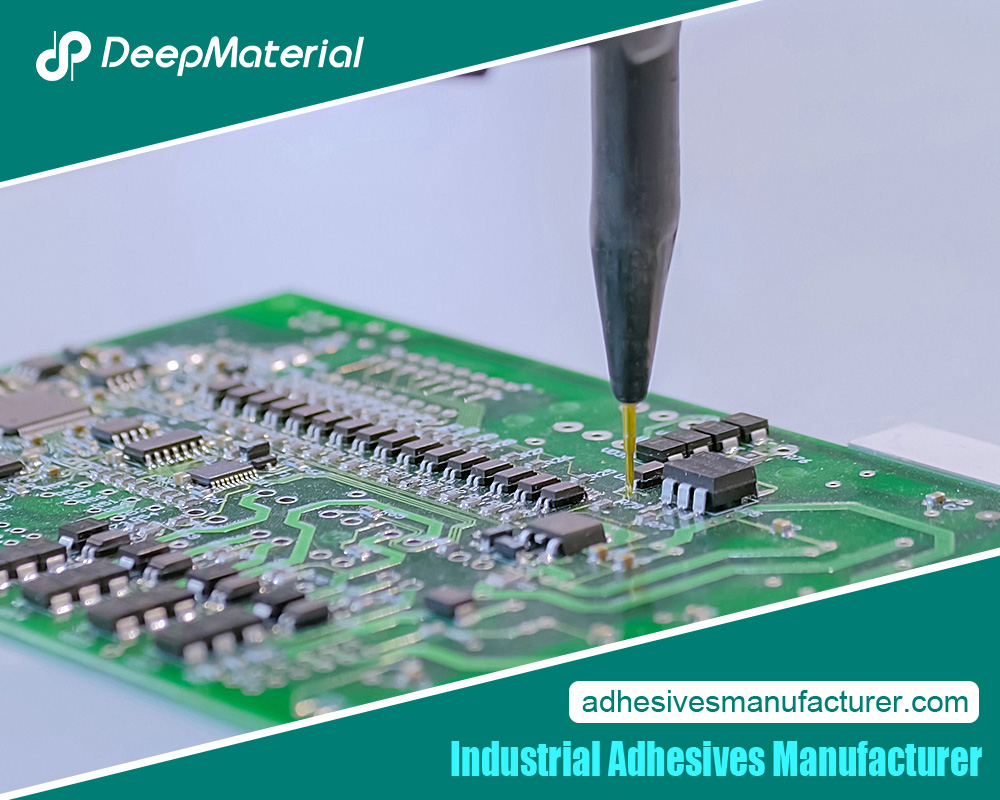

When it comes to all types of industrial and consumer glues, industrial adhesive manufacturers work to meet the needs of all customers. Manufacturing companies and product makers usually rely on these manufacturers to help them enhance their assembly quality and throughput. One of the benefits of using reliable adhesive manufacturers is that they can produce the right products to meet the demands of different brands. They can formulate and produce unique and innovative adhesives that can be applied in various industries. Additionally, many of these adhesive manufacturers can design the process of dispensing adhesives for industrial customers.

For more about a complete guide to industrial adhesive manufacturers and their products,you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.