Magnet Bonding Adhesive: The Key Link Connecting Magnetism and Innovation

Magnet Bonding Adhesive: The Key Link Connecting Magnetism and Innovation

In the rapid development of modern technology, Magnet Bonding Adhesive is gradually becoming an indispensable role. It is not just a simple bonding material but a key link connecting magnetism and various application fields, bringing innovation and breakthroughs to numerous industries.

Overview of Magnet Bonding Adhesive

Overview of Magnet Bonding Adhesive

Magnet Bonding Adhesive is a high-performance adhesive specifically designed for bonding magnets. It has a unique chemical composition and physical properties, capable of forming a firm, durable, and well-conductive and magnetic performance transfer bonding interface between magnets and other materials.

This adhesive typically consists of a resin matrix, curing agent, filler, and various additives. The resin matrix provides the basic viscosity and flexibility of the adhesive. The curing agent prompts the adhesive to cure under appropriate conditions to form a solid bonding structure. The filler helps improve the performance of the adhesive, such as enhancing strength and improving thermal conductivity. The additives endow the adhesive with specific properties, such as corrosion resistance and temperature resistance.

Performance Characteristics of Magnet Bonding Adhesive

High-strength Bonding

Magnet Bonding Adhesive can provide strong bonding strength, ensuring that magnets remain firmly connected under various harsh environments and high-load conditions. Its bonding strength can even exceed that of the magnets themselves, effectively preventing magnets from falling off or being damaged during use.

Good Magnetic Performance Transfer

Excellent Magnet Bonding Adhesive does not significantly weaken or interfere with the magnetic field distribution and magnetic force of the magnets when bonding, enabling good magnetic performance transfer and ensuring that the performance of the magnets is not affected after bonding.

Temperature Resistance

In many application scenarios, magnets need to operate in high-temperature or low-temperature environments. Magnet Bonding Adhesive has outstanding temperature resistance, can maintain a stable bonding effect under extreme temperature conditions, and will not crack or fall off due to temperature changes.

Corrosion Resistance

Whether in a humid environment or in contact with chemical substances, Magnet Bonding Adhesive can exhibit good corrosion resistance, protecting magnets and the bonding interface from erosion and extending the service life of magnets.

Electrical Insulation

In some applications requiring electrical insulation, Magnet Bonding Adhesive can provide reliable insulation performance, preventing current conduction between magnets and bonded components and ensuring the safe operation of the system.

Application Fields of Magnet Bonding Adhesive

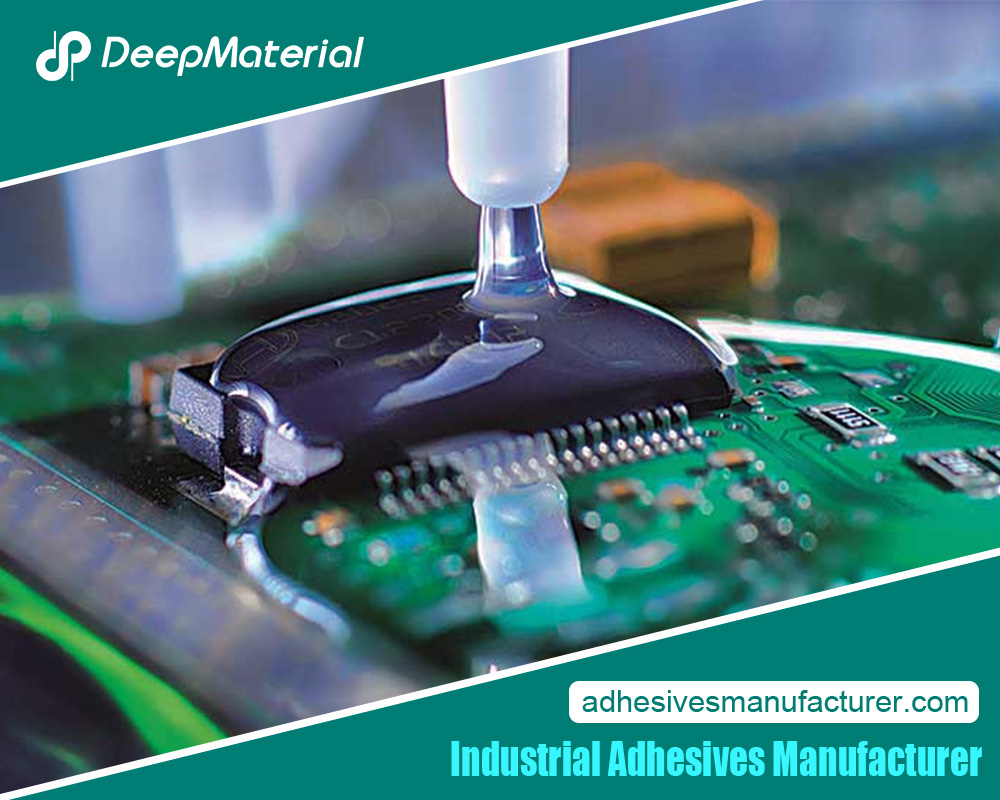

Electronics Field

In electronic devices such as mobile phones, computers, and tablets, magnets are widely used in components such as speakers, vibration motors, and wireless charging. Magnet Bonding Adhesive can precisely bond these magnets to circuit boards, housings, and other components, ensuring the performance and reliability of electronic devices.

For example, in the speakers of mobile phones, magnets need to be precisely bonded with voice coils and diaphragms to produce clear and loud sounds. The high-precision bonding ability and good magnetic performance transfer of Magnet Bonding Adhesive can ensure the sound quality and stability of the speakers.

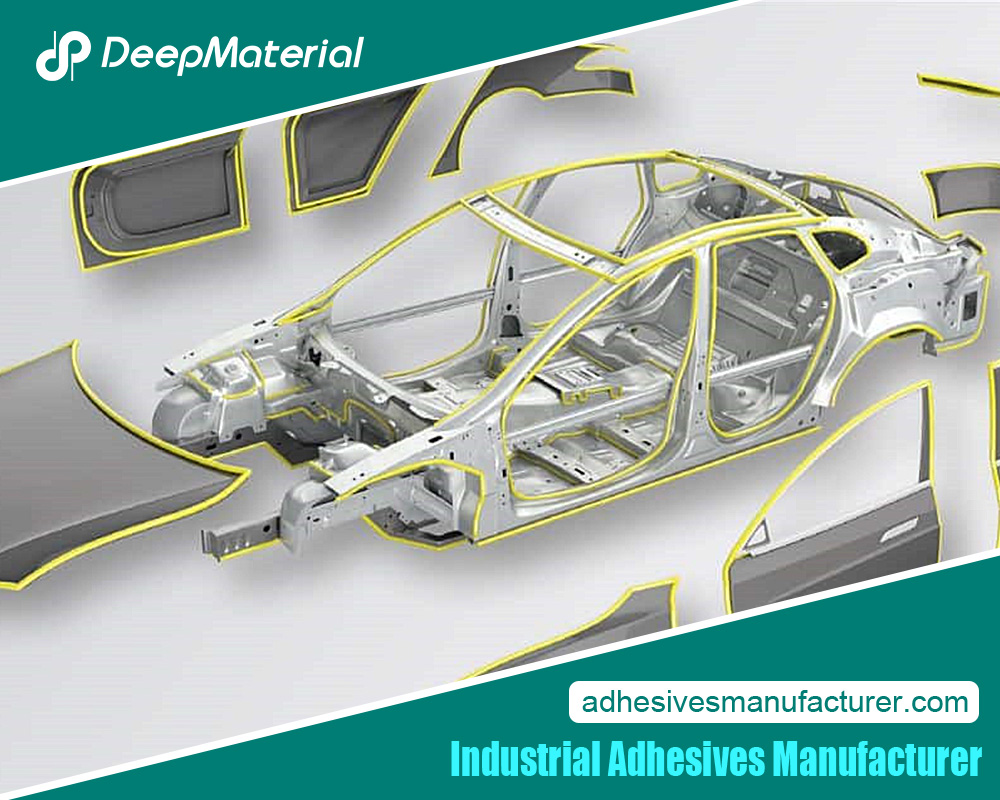

Automotive Field

The demand for magnets in the automotive industry is also increasing. Components such as electric power steering systems, motors, and sensors all rely on magnets. The application of Magnet Bonding Adhesive in the automotive field can improve the reliability and durability of automotive parts and reduce maintenance costs.

In the motors of electric vehicles, magnets need to withstand high-speed rotation and high-temperature tests. The high-strength bonding and temperature resistance of Magnet Bonding Adhesive can ensure the stable operation of magnets in the motor, improving the efficiency and lifespan of the motor.

Aerospace Field

The aerospace field has extremely high requirements for the performance of materials. Magnets play an important role in navigation systems, sensors, actuators, and other aspects. The lightweight, high-strength, temperature resistance, corrosion resistance, and other properties of Magnet Bonding Adhesive make it an ideal choice for magnet bonding in the aerospace field.

For example, in the attitude control system of satellites, magnets need to work stably in the space environment. Magnet Bonding Adhesive can ensure that magnets still maintain a good bonding effect under extreme conditions such as vacuum and radiation, ensuring the normal operation of satellites.

Medical Field

In medical devices such as magnetic resonance imaging (MRI) equipment, pacemakers, and dental instruments, magnets also have wide applications. The biocompatibility and safety of Magnet Bonding Adhesive can meet the strict requirements of the medical field for materials.

In MRI equipment, magnets need to be precisely bonded with superconducting coils and other components to generate a strong and uniform magnetic field. The high-precision bonding ability and good magnetic performance transfer of Magnet Bonding Adhesive can ensure the imaging quality and stability of MRI equipment.

Energy Field

In the energy field, such as wind power generation and solar power generation and other renewable energy systems, magnets also play an important role. Magnet Bonding Adhesive can firmly bond magnets to components such as generators and transformers, improving energy conversion efficiency and the reliability of the system.

For example, in wind turbines, magnets need to work under high-speed rotation and harsh environmental conditions. The high-strength bonding and weather resistance of Magnet Bonding Adhesive can ensure the long-term stable operation of magnets in wind turbines and reduce maintenance costs.

Development Trends of Magnet Bonding Adhesive

High-performance

With the continuous expansion of application fields and the increasing requirements for product performance, Magnet Bonding Adhesive will develop in the direction of higher strength, better magnetic performance transfer, more excellent temperature resistance, corrosion resistance, etc., to meet the needs of various extreme environments and high-performance applications.

Environmental Friendliness

The increasing awareness of environmental protection prompts Magnet Bonding Adhesive to develop in an environmentally friendly direction. The research and development of low volatile organic compound (VOC) emission, solvent-free, and biodegradable adhesives will become the development trend in the future to reduce environmental pollution.

Multi-functionality

To meet the needs of different application scenarios, Magnet Bonding Adhesive will have more functions, such as simultaneously having bonding, sealing, heat conduction, electrical conduction, etc., to simplify the process, reduce costs, and improve the comprehensive performance of the product.

Intelligence

With the development of intelligent technology, Magnet Bonding Adhesive is also expected to become intelligent. For example, by adding intelligent sensors or self-healing materials, the adhesive can monitor the state of the bonding interface in real-time and self-repair when damage occurs, improving the reliability and service life of the product.

Selection and Use of Magnet Bonding Adhesive

Choosing the Appropriate Adhesive

When choosing Magnet Bonding Adhesive, it is necessary to comprehensively consider factors such as the performance of the adhesive, the nature of the bonding materials, and the working environment based on the specific application scenarios and requirements. For example, for applications in high-temperature environments, adhesives with good temperature resistance should be selected; for applications requiring good magnetic performance transfer, adhesives with little impact on magnetic performance should be selected.

Surface Treatment

Appropriate surface treatment of magnets and the materials to be bonded is very important before bonding. Surface treatment can remove impurities such as oil, dust, and oxides on the surface, improve the roughness and activity of the surface, thereby enhancing the bonding effect of the adhesive. Common surface treatment methods include cleaning, grinding, sandblasting, and chemical treatment.

Gluing Process

The correct gluing process is crucial for ensuring bonding quality. The amount of glue applied should be moderate. Too little will result in insufficient bonding strength, and too much will cause waste and affect performance. The gluing method can be selected according to the specific situation, such as manual gluing, automatic gluing, or spray gluing. After gluing, it should be ensured that the adhesive is evenly distributed on the bonding interface and avoid the generation of bubbles.

Curing Conditions

Different types of Magnet Bonding Adhesive have different curing conditions, such as temperature, time, and pressure. During the curing process, the operation should be strictly in accordance with the curing requirements of the adhesive to ensure that the adhesive is fully cured and achieves the best bonding performance.

Conclusion

Conclusion

As the key link connecting magnetism and innovation, Magnet Bonding Adhesive plays an increasingly important role in various fields of modern technology. With the continuous advancement of technology and the increasing market demand, Magnet Bonding Adhesive will continue to develop and innovate, bringing more possibilities to the development of human society. When choosing and using Magnet Bonding Adhesive, we should fully understand its performance characteristics and application requirements and follow the correct operation process to ensure the best bonding effect and product performance. It is believed that in the future, Magnet Bonding Adhesive will show its unique charm in more fields and make greater contributions to promoting technological progress and industrial development.

For more about a complete guide to magnet bonding adhesive: the key link connecting magnetism and innovation, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.