The Role of Industrial Adhesives and Sealants Manufacturers in Modern Manufacturing

The Role of Industrial Adhesives and Sealants Manufacturers in Modern Manufacturing

Industrial adhesives and sealants are crucial in modern manufacturing, serving as essential components for bonding, sealing, and surface protection in various industries. These substances, from automotive to construction, packaging, and electronics, are integral in creating durable, high-performance products. As the demand for innovative and efficient solutions grows, industrial adhesives and sealant manufacturers have emerged as key players in ensuring that industries meet evolving needs. This article explores the critical roles of these manufacturers, the types of adhesives and sealants they produce, and the factors driving advancements in their development.

The Role of Industrial Adhesives and Sealants in Manufacturing

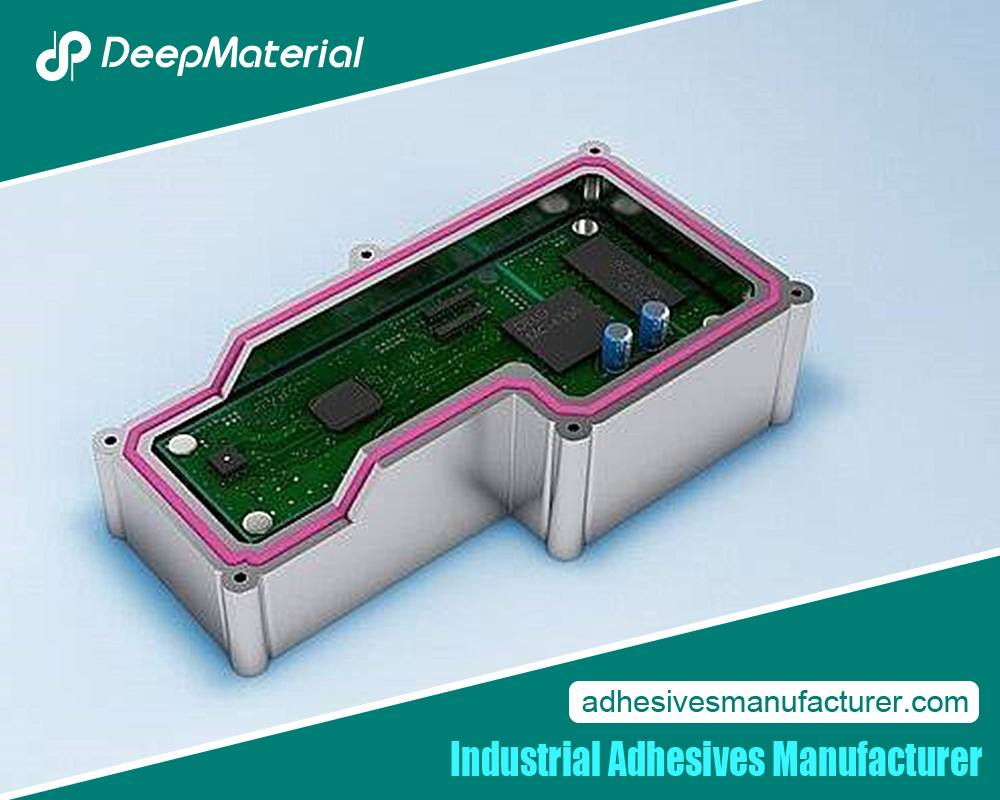

Industrial adhesives and sealants bond materials together or protect against environmental elements, preventing leakage, corrosion, or damage. These products are used in various applications across various industries, including automotive, aerospace, construction, electronics, packaging, and healthcare.

Key Functions of Industrial Adhesives

- Bonding:Adhesive bond materials often replace traditional fastening methods like welding, screws, and nails.

- Stress Distribution:They help distribute stress uniformly across surfaces, preventing damage from vibrations or impacts.

- Durability:Many adhesives are designed to be long-lasting, ensuring that products remain intact even under challenging conditions.

Key Functions of Industrial Sealants

- Sealing:Sealants are primarily used to fill gaps or joints, preventing the entry of moisture, air, dust, or contaminants.

- Waterproofing:Many sealants are designed to withstand water exposure, protecting the integrity of the product.

- Thermal Insulation:Sealants can also provide thermal resistance, reducing heat transfer between materials.

Types of Adhesives and Sealants

Various types of adhesives and sealants are designed to meet specific needs. These materials are engineered for different applications and environments, providing customized solutions for industrial challenges.

Types of Adhesives

Epoxy Adhesives:

- Characteristics:Known for their exceptional strength and durability, epoxy adhesives offer excellent bonding properties.

- Applications:Used in automotive, aerospace, and construction for bonding metals, composites, and plastics.

Polyurethane Adhesives:

- Characteristics:These adhesives are highly flexible, providing good resistance to moisture, heat, and chemicals.

- Applications: Commonly used in construction and automotive industries.

Acrylic Adhesives:

- Characteristics:Acrylic adhesives are fast-curing and provide excellent bonding strength, especially in transparent materials.

- Applications:Often used in packaging, automotive, and electronics industries.

Silicone Adhesives:

- Characteristics:Silicone adhesives are known for their flexibility and resistance to extreme temperatures and environmental conditions.

- Applications:Used in electronics, automotive, and construction industries where high heat resistance is required.

Types of Sealants

Silicone Sealants:

- Characteristics:Known for their flexibility and ability to resist extreme temperatures, silicone sealants provide long-lasting protection.

- Applications:Commonly used in construction, automotive, and electronics.

Polyurethane Sealants:

- Characteristics:Polyurethane sealants offer excellent resistance to moisture, UV light, and chemicals, making them ideal for outdoor applications.

- Applications:Used in the construction of windows, doors, and roofs.

Butyl Rubber Sealants:

- Characteristics:These sealants are known for their superior adhesion to various surfaces and resistance to water and weathering.

- Applications: Frequently used in roofing, automotive, and electrical applications.

Acrylic Sealants:

- Characteristics:Acrylic sealants provide a smooth finish and are resistant to aging, weathering, and UV degradation.

- Applications: Often used in the construction and automotive industries.

Importance of Industrial Adhesives and Sealants Manufacturers

Industrial adhesives and sealants manufacturers are vital to the global manufacturing ecosystem. They are responsible for producing, developing, and innovating bonding and sealing solutions that meet the specific needs of industries worldwide.

Research and Development

- Industrial adhesives and sealants manufacturers invest heavily in research and development (R&D) to innovate and create more effective solutions. As industries evolve and new materials are introduced, manufacturers must develop adhesives and sealants that offer enhanced performance, cost-effectiveness, and environmental sustainability.

- Sustainability:There is a growing focus on developing eco-friendly adhesives and non-toxic and recyclable sealants.

- Customization:Manufacturers create customized solutions to meet different industries’ specific bonding or sealing needs, ensuring the right product is available for each application.

Meeting Industry Demands

As technology advances, industrial adhesives and sealants manufacturers must continuously adapt to meet the growing demands of different sectors. For example:

- Aerospace: With increasing requirements for lightweight materials, adhesives, bond composites, and metals, reducing aircraft weight without compromising safety or performance.

- Automotive:In the automotive industry, adhesives replace traditional fasteners, enabling manufacturers to produce lighter, more fuel-efficient vehicles with improved safety features.

- Construction:Sealants are used extensively in the construction industry to ensure buildings are energy-efficient, waterproof, and weather-resistant.

Global Supply Chains and Collaboration

Industrial adhesives and sealants manufacturers are integral to global supply chains. They work closely with raw material suppliers, original equipment manufacturers (OEMs), and end users to ensure that the right products are available at the right time. This collaboration is essential for industries like automotive and electronics, where the demand for high-performance materials is high.

- Supply Chain Management:Manufacturers often produce just in time, ensuring that products are available when needed.

- Collaborative Innovation:Manufacturers partner with industry leaders to innovate and develop advanced materials that solve emerging challenges.

Trends Driving Innovation in Industrial Adhesives and Sealants

The industrial adhesives and sealants market is driven by various trends pushing the boundaries of what these materials can achieve. The demand for more innovative, more efficient solutions is a key factor in the continued development of adhesives and sealants.

Advances in Sustainability

Sustainability is a growing concern for industries, and adhesives and sealants manufacturers are rising to the challenge by developing eco-friendly products. Innovations include:

- Water-based adhesives: Reducing the need for harmful solvents.

- Biodegradable sealants: Minimizing the environmental impact of used materials.

- Recyclable adhesives: Enabling easier recycling and reducing waste in the manufacturing process.

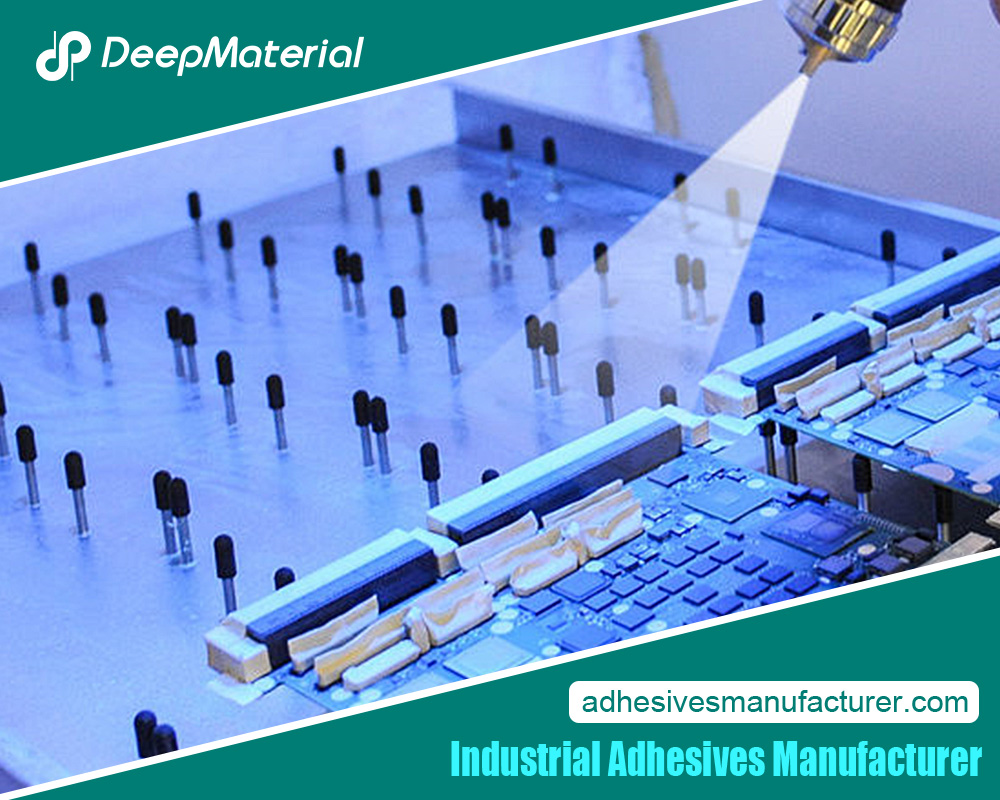

Automation and Smart Technologies

As manufacturing processes become increasingly automated, industrial adhesives and sealants must also evolve to meet the demands of robotics and innovative technologies. Adhesives are now being designed to withstand the high-speed operations of automated systems, and sealants are being engineered to perform under more precise conditions.

- Automated application:Manufacturers are developing adhesives that robots can use with precision and accuracy, reducing waste and improving efficiency.

- Innovative adhesives: These adhesives can respond to changes in temperature, humidity, or pressure, ensuring that bonds remain intact under varying conditions.

Nanotechnology and Enhanced Performance

Nanotechnology plays a significant role in developing next-generation adhesives and sealants. By manipulating materials at the molecular level, manufacturers can create adhesives with enhanced strength, flexibility, and durability.

- Improved bonding strength:Nanomaterials increase the surface area for bonding, resulting in more substantial and durable adhesives.

- Enhanced resistance:Nanotechnology can improve the resistance of sealants to extreme conditions, such as high temperatures or chemicals.

Conclusion

Industrial adhesives and sealant manufacturers play an essential role in the global manufacturing ecosystem, providing critical solutions for industries ranging from automotive and aerospace to construction and electronics. Through constant innovation and research, these manufacturers are creating advanced products that meet the growing demands for strength, durability, sustainability, and efficiency. As industries evolve, industrial adhesives and sealants will remain central to developing cutting-edge technologies, providing the necessary tools for modern manufacturing to thrive.

For more about a complete guide to the role of industrial adhesives and sealants manufacturers in modern manufacturing, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.