Metal to metal Bonding Adhesives: A Comprehensive Overview for Industry Professionals

Metal to metal Bonding Adhesives: A Comprehensive Overview for Industry Professionals

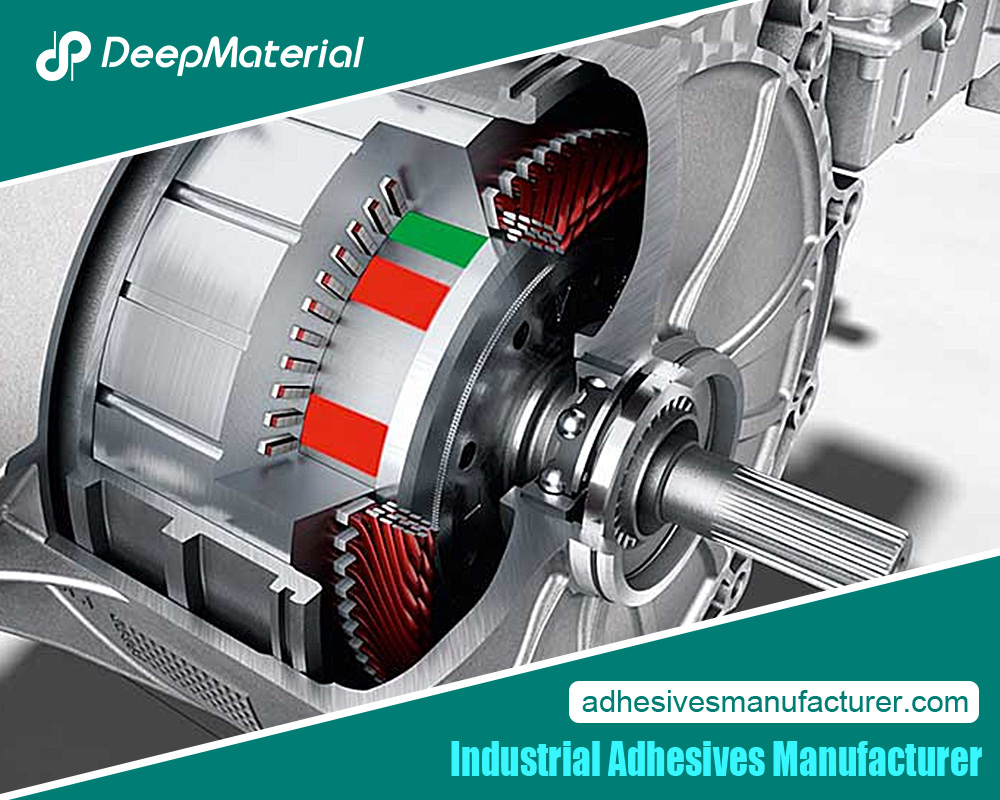

In modern manufacturing and construction, the quest for strong, durable, and efficient bonding solutions has led to the widespread adoption of metal to metal bonding adhesives. These specialized adhesives have revolutionized how industries approach the assembly of metal components, providing alternatives to traditional methods like welding and mechanical fastening. This blog post delves into the intricacies of Metal to metal bonding adhesives, exploring their types, applications, benefits, and best practices for optimal performance.

What Are Metal to metal Bonding Adhesives?

Definition

Metal to metal bonding adhesives are formulations designed to create solid and lasting bonds between metal surfaces. They utilize a combination of mechanical interlocking and chemical adhesion, offering a unique solution for various industrial applications.

Composition

Most metal bonding adhesives are made from polymers, which can include:

- Epoxies

- Acrylics

- Polyurethanes

- Silicones

Each type has unique properties and uses, making selecting the suitable adhesive for specific applications essential.

Types of Metal to metal Bonding Adhesives

Epoxy Adhesives

Description: Epoxy adhesives consist of a resin and hardener that, when mixed, form a strong, durable bond.

Properties:

- High shear and tensile strength.

- Excellent resistance to chemicals and extreme temperatures.

- Cures at room temperature or with heat.

Acrylic Adhesives

Description: Acrylic adhesives are known for their rapid curing and versatility.

Properties:

- Suitable for bonding dissimilar materials, such as Metal to plastic.

- High impact resistance.

- It can be applied to slightly contaminated surfaces.

Polyurethane Adhesives

Description: Polyurethane adhesives provide flexibility and excellent bonding characteristics.

Properties:

- Resistant to moisture and UV light.

- Suitable for applications that experience thermal expansion.

- It offers shock-absorbing qualities.

Silicone Adhesives

Description: Silicone adhesives are known for their high-temperature resistance and flexibility.

Properties:

- It is ideal for applications requiring movement or thermal cycling.

- Excellent weather resistance and durability.

- They are typically used in environments exposed to moisture or extreme temperatures.

Applications of Metal to Metal Bonding Adhesives

Automotive Industry

- Structural Bonding: Used to bond chassis and frame components, reducing weight while maintaining strength.

- Repair Solutions:Ideal for fixing damaged parts without welding, leading to quicker repairs and lower costs.

Aerospace Sector

- Aircraft Assembly: Utilized to bond lightweight components to enhance fuel efficiency.

- In-Field Repairs: Quick-setting adhesives allow for efficient repairs on-site, minimizing downtime.

Construction

- Metal Frameworks: Adhesives are used to assemble steel structures and precast concrete.

- Facade and Roofing Applications:Provide weatherproof bonding solutions for external elements.

Manufacturing

- Heavy Machinery Assembly:Ideal for joining components where welding is impractical.

- Tool and Die Making:Bonds complex shapes and precision parts effectively.

Benefits of Metal to metal Bonding Adhesives

Strength and Durability

- High shear and tensile strength provide long-lasting bonds.

- Resistance to fatigue and thermal cycling enhances durability.

Versatility

- Capable of bonding various metals, including aluminum, steel, and stainless steel.

- Suitable for a range of applications across different industries.

Cost-Effectiveness

- Reduces the need for mechanical fasteners and specialized welding equipment.

- Decreases labor costs associated with traditional bonding methods.

Environmental Resistance

- Many adhesives are designed to withstand exposure to chemicals, moisture, and extreme temperatures.

- Ideal for applications in harsh environments.

Ease of Use

- Simple application processes often require minimal surface preparation.

- Quick curing times improve production efficiency.

Best Practices for Using Metal Bonding Adhesives

Surface Preparation

- Cleanliness:Ensure surfaces are free from oil, grease, dirt, and other contaminants. Clean with solvents or specialized cleaners as necessary.

- Roughening:Mechanical abrasion or sanding can enhance the surface area for adhesion, improving bond strength.

Application Techniques

- Uniform Application: Apply the adhesive evenly to prevent weak spots. Consider using a dispensing gun for controlled application.

- Proper Mixing:For two-part adhesives like epoxies, ensure thorough mixing of the resin and hardener to achieve optimal bonding performance.

Environmental Considerations

- Temperature and Humidity: Monitor environmental conditions during application and curing, as extreme temperatures and high humidity can affect bond strength.

- Curing Time:Allow sufficient curing time as specified by the manufacturer. This is crucial for achieving maximum bond strength.

Testing and Quality Control

- Bond Strength Tests: Perform tests to evaluate the adhesive’s performance under expected loads and conditions.

- Regular Inspections:Implement a routine inspection schedule to assess the integrity of bonded joints over time.

Troubleshooting Common Issues

Poor Bond Strength

- Causes: Contaminated surfaces, improper mixing, or inadequate curing time.

- Solutions: Ensure surfaces are thoroughly cleaned, mix components as instructed, and allow appropriate curing conditions.

Adhesive Failure

- Causes:Exposure to extreme conditions beyond the adhesive’s specifications or mechanical overload.

- Solutions:Evaluate the application environment and select adhesives for those conditions.

Surface Compatibility

- Causes: Some adhesives may not bond well with certain metal types.

- Solutions:Test the adhesive on a small metal sample before applying it on a full-scale scale.

Future Trends in Metal Bonding Adhesives

The landscape of Metal to metal bonding adhesives is evolving rapidly and is driven by advancements in materials science, engineering, and industry demands. As industries seek stronger, lighter, and more durable connections, several emerging trends promise to shape the future of adhesive technologies. Here are some key trends to watch:

Increased Use of High-Performance Materials

- Advanced Formulations: Developing new epoxy and polyurethane blends for enhanced thermal and mechanical properties.

- Composite Materials:There is a rising demand for adhesives that bond metals with composites, promoting lighter and more efficient structures.

Sustainability and Eco-Friendly Solutions

- Bio-Based Adhesives: Growing interest in adhesives derived from renewable resources to reduce environmental impact.

- Reduced Volatile Organic Compounds (VOCs): Innovations aimed at lowering VOC emissions in adhesive formulations, making products safer for users and the environment.

Smart Adhesives

- Self-Healing Properties:Development of adhesives that can repair themselves after damage, extending the life of bonded joints.

- Temperature and pH Sensitivity: Adhesives that change properties based on environmental conditions allow adaptive bonding solutions.

Automation and Application Technology

- Robotic Dispensing: Increased use of automated systems for adhesive application, ensuring precision and consistency in bonding processes.

- Real-Time Monitoring: Implementation of sensors to monitor adhesive application and curing processes for enhanced quality control.

Enhanced Performance Characteristics

- High-Temperature Resistance: Adhesives capable of maintaining performance in extreme temperature environments, particularly in aerospace and automotive applications, are in demand.

- Impact and Fatigue Resistance: Development of adhesives designed to withstand repeated stress and strain, improving longevity in dynamic applications.

Customization and Tailored Solutions

- Industry-Specific Formulations:Growth in the demand for customized adhesive solutions tailored to specific applications, such as automotive, aerospace, and electronics.

- Modular Systems:Creation of modular adhesive systems that can be easily adapted for various bonding challenges.

Regulatory Compliance and Safety

- Stricter Regulations:Anticipation of tighter regulations around adhesive materials, pushing manufacturers to innovate while ensuring compliance with safety standards.

- Transparency in Material Sourcing: Increased consumer demand for information on the sourcing and safety of adhesive components.

Market Growth and Global Expansion

- Emerging Markets: Expansion into developing regions as industrialization increases, driving the demand for efficient bonding solutions.

- Collaborative Innovation: Partnerships between adhesive manufacturers, material scientists, and end-users to foster innovation and address specific bonding challenges.

Conclusion

Conclusion

Metal to metal bonding adhesives are vital to modern manufacturing, offering a strong, versatile, cost-effective alternative to traditional bonding methods. Understanding the various types of adhesives, their applications, benefits, and best practices can significantly enhance product quality and operational efficiency across multiple industries. As technology evolves, these adhesives will play an increasingly important role in advancing manufacturing processes and meeting the demands of an ever-changing industrial landscape. Embracing these innovations will empower professionals to achieve superior project results, driving success in their respective fields.

For more about a complete guide to metal to metal bonding adhesives: a comprehensive overview for industry professionals, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.