Electronics Encapsulation Epoxy: A Comprehensive Guide

Electronics Encapsulation Epoxy: A Comprehensive Guide

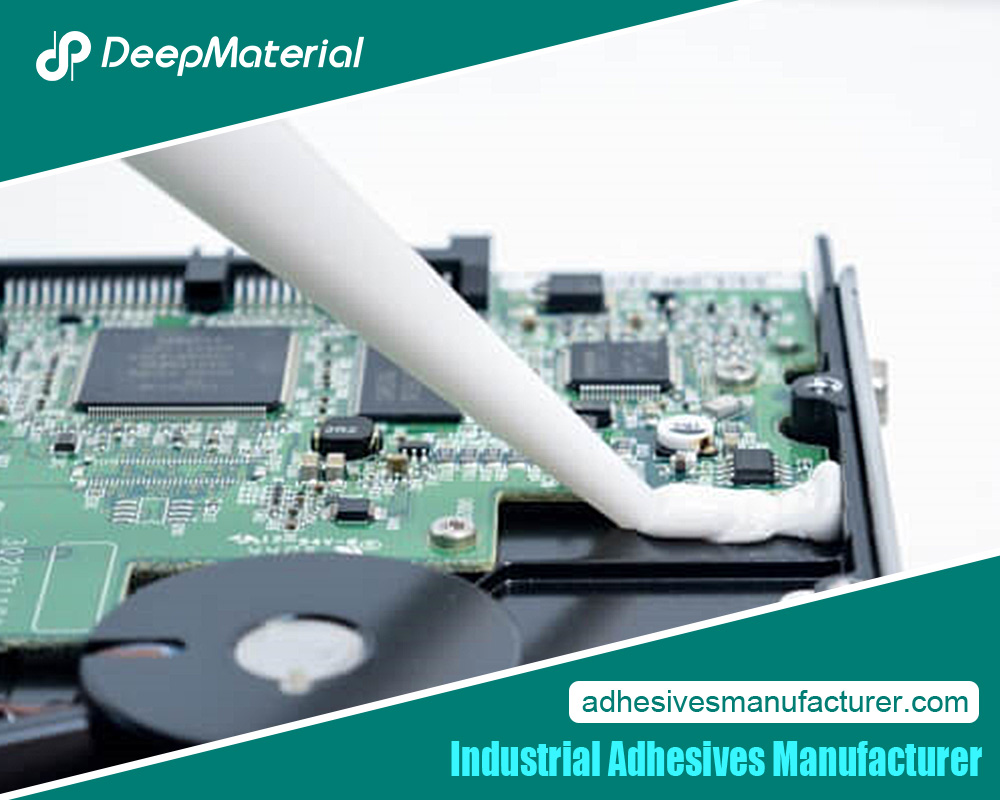

In the world of electronics manufacturing and design, the protection of sensitive components from environmental hazards is paramount. One of the most reliable methods of safeguarding these components is through encapsulation. Encapsulation involves covering or enclosing electronic assemblies and parts with a protective material. Among the various materials used for this purpose, electronics encapsulation epoxy stands out for its excellent mechanical strength, thermal resistance, and insulating properties. This article delves into the properties, applications, and benefits of electronic encapsulation epoxy, as well as its role in ensuring the longevity and reliability of electronic devices.

What is Electronics Encapsulation Epoxy?

Electronics encapsulation epoxy is a two-component polymer used to encapsulate, protect, and insulate electronic components from external influences. It is composed of a resin and a hardener, which, when mixed, undergo a chemical reaction to form a solid, durable, and protective layer around electronic parts.

Encapsulation epoxy provides a physical barrier to moisture, dust, chemicals, and mechanical stress. In addition to its protective properties, epoxy encapsulation enhances the electrical insulation of components, preventing short circuits and providing stability in fluctuating environments. Due to its excellent adhesion and protective abilities, epoxy is widely used in industries ranging from automotive electronics to consumer devices and industrial equipment.

Properties of Electronics Encapsulation Epoxy

- Thermal Resistance: One of the critical properties of epoxy encapsulation is its ability to withstand high temperatures. In electronic applications, components often operate at elevated temperatures. Encapsulation epoxy can endure a wide range of temperatures without losing its structural integrity, making it ideal for applications in harsh environments.

- Electrical Insulation: Epoxy is an excellent insulator, protecting electronic circuits from short circuits and electrical failures. Its dielectric properties make it suitable for applications requiring sensitive component isolation.

- Moisture and Chemical Resistance: Electronics are often exposed to moisture, humidity, and chemicals, which can lead to corrosion and degradation of components. Epoxy encapsulation creates a barrier that prevents moisture and chemicals from reaching the electronic parts, extending their lifespan.

- Adhesion: Epoxy has remarkable adhesion properties, allowing it to bond securely to various substrates, including metals, plastics, and ceramics. This ensures that the encapsulated components remain firmly enclosed, even in challenging conditions.

- Mechanical Strength: Encapsulation epoxy provides robust mechanical protection, safeguarding electronic components from shocks, vibrations, and physical impacts. This makes it suitable for applications where electronics are subjected to harsh mechanical stresses, such as automotive or aerospace environments.

- UV Stability: Some encapsulation epoxies are designed to resist UV light, preventing degradation or yellowing when exposed to sunlight or other UV sources. This is particularly important for outdoor electronic applications.

Types of Epoxy for Electronics Encapsulation

Types of Epoxy for Electronics Encapsulation

Different epoxy formulations are designed to meet specific requirements for various electronic applications. These types include:

- Rigid Epoxy: Rigid epoxies offer excellent mechanical protection and are commonly used for applications requiring high strength and thermal resistance. However, as they lack flexibility, they may not be suitable for environments with significant thermal expansion.

- Flexible Epoxy: Flexible epoxies are designed to accommodate thermal expansion and contraction. These epoxies maintain their protective properties even in fluctuating temperatures, making them ideal for applications where components experience regular thermal cycling.

- UV-Curable Epoxy: UV-curable epoxies provide rapid curing when exposed to ultraviolet light. They are commonly used in applications requiring fast processing times, such as in high-speed manufacturing environments.

- Thermally Conductive Epoxy: Thermally conductive epoxies are used when heat dissipation is a priority. These epoxies contain fillers that improve heat transfer, helping to keep components cool during operation.

- Low-Viscosity Epoxy: Low-viscosity epoxies are designed to flow quickly, making them ideal for applications requiring epoxy to penetrate small gaps and spaces within electronic assemblies.

Applications of Electronics Encapsulation Epoxy

Electronic encapsulation epoxy is utilised in various industries to enhance the durability and reliability of electronic components. Some of the most common applications include:

Consumer Electronics

Encapsulation epoxy is used to protect delicate components such as microchips, sensors, and circuit boards in consumer electronics such as smartphones, tablets, and wearable devices. This helps shield the devices from moisture, dust, and accidental drops, ensuring long-term performance and reliability.

Automotive Electronics

The automotive industry heavily relies on encapsulation epoxy to protect the sensitive electronic systems found in modern vehicles. From engine control units (ECUs) to sensors and infotainment systems, epoxy encapsulation ensures that these components can withstand the harsh conditions of the automotive environment, including extreme temperatures, vibrations, and chemical exposure.

Aerospace and Defense

Encapsulation epoxy protects avionics, communication systems, and navigation electronics in aerospace and defence applications, where reliability is critical. These components must operate flawlessly in extreme environments, including high altitudes, radiation, and temperature fluctuations.

Industrial Equipment

Industrial machinery often contains sensitive electronics exposed to dust, moisture, and mechanical stress. Encapsulation epoxy protects components such as sensors, controllers, and power modules in industrial automation, robotics, and heavy machinery.

Medical Devices

Medical electronics, such as diagnostic equipment and wearable health monitors, require protection from bodily fluids, moisture, and contamination. Encapsulation epoxy provides a reliable barrier that ensures the safety and functionality of these life-saving devices.

Power Electronics

Encapsulation epoxy plays a crucial role in protecting components from high voltage and heat in power electronics, including transformers, inverters, and power supplies. This ensures efficient and reliable operation, especially in applications that demand continuous power delivery.

The Process of Epoxy Encapsulation

Encapsulating electronics with epoxy involves several steps to ensure a successful application. Below is an outline of the general procedure:

Surface Preparation

Before applying epoxy, it is essential to prepare the surface of the electronic components. This involves cleaning the components to remove any dust, grease, or contaminants affecting the epoxy’s adhesion. Proper surface preparation ensures a strong bond between the epoxy and the components.

Mixing the Epoxy

Electronics encapsulation epoxy is in two components: a resin and a hardener. These components must be mixed in precise proportions to achieve the desired properties. Mixing should be done carefully to avoid introducing air bubbles, which can compromise the encapsulation.

Application of the Epoxy

Once the epoxy is mixed, it is applied to the electronic components using various methods, such as dispensing, pouring, or spraying. The method used depends on the size and complexity of the encapsulated components. Ensuring that the epoxy completely covers the components and fills any gaps or voids is crucial.

Curing

After application, the epoxy undergoes a curing process, during which it hardens and forms a solid protective layer. Depending on the type of epoxy used, the curing process can be accelerated by using heat or ultraviolet light. Full curing ensures the epoxy reaches its maximum mechanical strength and protective capabilities.

Final Inspection

Once the epoxy has cured, the encapsulated components are inspected for defects, such as incomplete coverage, air bubbles, or cracks. Defects are addressed before the components are used in their final applications.

Advantages of Using Encapsulation Epoxy

- Enhanced Durability: Encapsulation epoxy significantly improves the durability of electronic components by protecting them from environmental factors, mechanical stress, and electrical interference.

- Extended Lifespan: By shielding components from moisture, chemicals, and temperature fluctuations, epoxy encapsulation increases the overall lifespan of electronic devices.

- Improved Reliability: Epoxy encapsulation reduces the risk of component failure, ensuring that electronics perform reliably even in challenging conditions.

- Cost-Effective: Using encapsulation epoxy can reduce the need for frequent repairs and replacements, lowering the overall cost of maintaining electronic systems.

- Customizable: Epoxy formulations can be tailored to meet specific requirements, such as flexibility, thermal conductivity, or rapid curing, making them versatile for various applications.

Conclusion

Conclusion

In conclusion, electronic encapsulation epoxy plays a vital role in ensuring the reliability and longevity of electronic components across various industries. With its excellent thermal resistance, electrical insulation, and mechanical strength, epoxy encapsulation provides a robust protective barrier that safeguards electronics from environmental and mechanical stresses. Epoxy encapsulation ensures that sensitive components remain functional and reliable, even in the most demanding conditions, whether in consumer electronics, automotive systems, aerospace, or industrial equipment. As technology continues to evolve, the importance of electronic encapsulation epoxy will only grow, making it an indispensable material in modern electronics manufacturing.

For more about a complete guide to electronics encapsulation epoxy: a comprehensive guide, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.