One-Part Structural Adhesives Supplier: A Comprehensive Guide

One-part structural adhesives are essential in various industries for applications that demand robust, durable, and high-performing bonding solutions. Unlike two-part adhesives, one-part adhesives require no mixing, making them more accessible and convenient for manufacturing and construction. This article provides a detailed overview of one-part structural adhesives, their properties, types, applications, and factors to consider when selecting a supplier. Additionally, it outlines the qualities that reputable suppliers offer and why partnering with a reliable adhesive provider can benefit businesses across multiple sectors.

What Are One-Part Structural Adhesives?

One-part structural adhesives are single-component adhesives formulated to provide strong, reliable bonds between various substrates. These adhesives cure or harden when exposed to specific environmental conditions, such as heat, moisture, or light, depending on the type of adhesive. Unlike two-part adhesives, which require precise mixing of components before application, one-part adhesives eliminate the risk of mixing errors, simplify the application process, and reduce preparation time. These adhesives are used in automotive, aerospace, construction, and electronics industries for applications where high strength, durability, and resistance to environmental factors are essential.

Critical Benefits of One-Part Structural Adhesives

- Ease of Use:One-part adhesives streamline the bonding process by eliminating the need for mixing. This feature enhances efficiency, reduces material waste, and improves product quality.

- Consistent Performance:One-part adhesives offer consistent performance and reliable bonding strength with a single component, minimizing variability in application outcomes.

- High Strength and Durability:These adhesives provide robust structural bonds, making them ideal for load-bearing applications and demanding environments.

- Versatile Application:One-part structural adhesives can bond various materials, including metals, composites, plastics, and ceramics.

- Resistance to Environmental Stressors:Many one-part adhesives resist extreme temperatures, moisture, chemicals, and mechanical stresses, which prolong the lifespan of bonded components.

Types of One-Part Structural Adhesives

One-part structural adhesives come in various formulations to meet the unique demands of specific applications. Some of the most common types include:

Epoxy-Based Adhesives

Epoxy-based one-part adhesives cure at elevated temperatures and provide strong bonds with high shear and peel strength. These adhesives are highly resistant to chemicals, making them suitable for demanding environments such as automotive and aerospace applications. They can also effectively bond dissimilar materials, including metals, ceramics, and some plastics.

Polyurethane one-part adhesives cure when exposed to moisture and offer a balance between flexibility and strength. They are highly moisture-resistant and can withstand high and low temperatures, making them popular in the construction and automotive industries for applications that demand durability and vibration resistance.

Silicone Adhesives

Silicone-based one-part adhesives are known for their flexibility, temperature resistance, and UV stability. They are ideal for applications requiring bonding in extreme temperature environments, such as in the electronics and aerospace sectors. These adhesives are also helpful for sealing purposes, as they maintain elasticity over time.

Acrylic Adhesives

One-part acrylic adhesives offer fast curing times and intense bonds. They can adhere well to metals and plastics, making them suitable for various applications in automotive, appliances, and medical device assembly. These adhesives are also resistant to environmental factors like heat and chemicals.

Cyanoacrylate Adhesives

They are also known as instant adhesives; cyanoacrylates bond quickly upon contact with moisture. Although they are often used for smaller, precise applications, high-strength formulations are available for structural bonding. Cyanoacrylates are versatile and can bond with different materials, including metals, plastics, and rubber.

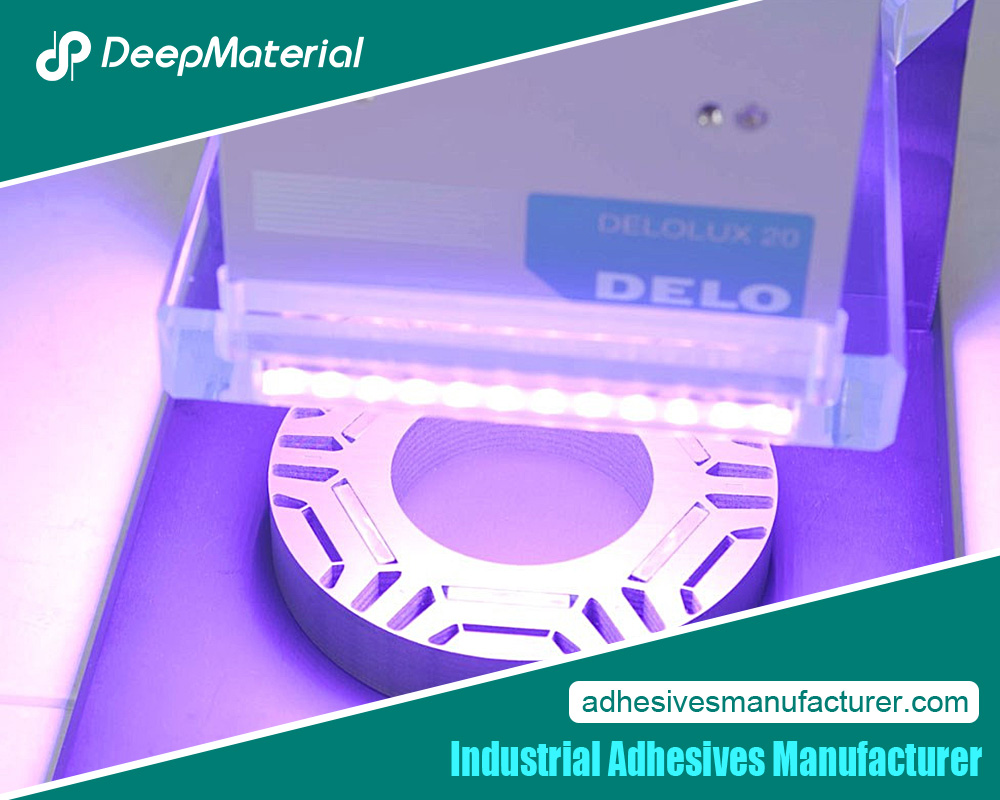

UV-Curable Adhesives

UV-curable one-part adhesives harden when exposed to ultraviolet light. They offer fast curing times and precise control, making them ideal for electronics, medical devices, and optical industries. However, they are only suitable for applications with UV light reaching the bonding area.

Applications of One-Part Structural Adhesives

One-part structural adhesives have a wide range of applications across multiple industries. Here are some of the primary uses:

Automotive Industry

In the automotive sector, one-part adhesives bond components that require high strength and resistance to vibrations and temperature changes. Applications include bonding body panels, structural frames, engine components, and interior elements. One-part adhesives contribute to vehicle weight reduction, which enhances fuel efficiency and performance.

Aerospace Industry

Aerospace applications demand adhesives that withstand extreme temperatures, high altitudes, and intense mechanical stresses. One-part adhesives are vital in assembling aircraft parts, bonding metal and composite materials, and providing lightweight, durable solutions that meet rigorous aerospace standards.

Construction and Infrastructure

One-part structural adhesives are used extensively in construction to bond metal, glass, concrete, and composite materials. They provide a solid alternative to mechanical fasteners and contribute to the structural integrity of buildings and infrastructure. These adhesives are used for windows, doors, panels, and other load-bearing elements.

Electronics and Electrical Industry

In the electronics industry, one-part adhesives bond components in printed circuit boards, sensors, and housings. UV-curable adhesives are particularly popular for delicate electronics assembly due to their fast curing time and precision. Adhesives used in this sector must meet high thermal resistance and dielectric strength standards.

Medical Devices

Medical device manufacturing demands adhesives that meet biocompatibility standards and provide strong bonds for plastics, metals, and ceramics. One-part adhesives used in this field must also be resistant to sterilization processes, ensuring the longevity and safety of medical devices.

Renewable Energy

The renewable energy sector utilizes one-part structural adhesives for bonding solar panels, wind turbine components, and batteries. These adhesives provide weather and UV resistance, contributing to the durability and reliability of renewable energy installations.

Selecting a Reliable One-Part Structural Adhesive Supplier

Choosing the right supplier is critical to ensuring the adhesives meet industry standards and project specifications. When selecting a supplier for one-part structural adhesives, consider the following factors:

Quality and Certification

A reputable supplier should provide adhesives that meet industry standards and certifications, such as ISO, RoHS, and REACH compliance. Adhering to these standards ensures the adhesives are safe, reliable, and suitable for use in specific industries, such as aerospace and medical devices, where strict regulations apply.

Product Range and Customization

A good supplier should offer a diverse product range, including various types of one-part structural adhesives tailored to different applications. Additionally, some suppliers may provide customization options to meet unique bonding requirements, whether for temperature resistance, curing speed, or adhesive strength.

Technical Support and Expertise

Technical support is essential for helping clients select the appropriate adhesive for their specific application. Reputable suppliers have knowledgeable technical teams that offer guidance, testing services, and troubleshooting support. This ensures that customers can optimize adhesive performance and address any challenges during application.

Research and Development (R&D) Capability

Innovative suppliers invest in research and development to improve adhesive formulations, enhance performance characteristics, and meet market demands. Suppliers with robust R&D capabilities can deliver state-of-the-art adhesives that meet evolving industry needs, such as improved environmental resistance, faster curing times, or sustainable ingredients.

Sustainability Initiatives

As industries shift towards more environmentally friendly practices, selecting a supplier committed to sustainability can be beneficial. Look for suppliers prioritizing sustainable manufacturing practices, offering low-VOC or solvent-free adhesives, and using recyclable packaging materials.

Global Reach and Supply Chain Reliability

A reliable supplier should have an efficient supply chain and a global distribution network. This ensures timely delivery and product availability, even during supply chain disruptions. A global supplier can provide consistent product quality and service for international companies across multiple locations.

Advantages of Partnering with a Reputable One-Part Structural Adhesive Supplier

Working with a reputable supplier provides numerous benefits to businesses across various industries:

- Enhanced Product Quality:High-quality adhesives contribute to the overall quality of the final product, ensuring solid and reliable bonds that meet industry standards.

- Efficiency and Cost Savings:Reliable adhesives reduce waste, minimize rework, and shorten production times, leading to cost savings over time.

- Improved Performance and Durability:Superior adhesives enhance product performance, durability, and resistance to environmental factors, ensuring that bonded components last longer.

- Access to Expertise and Support:Reputable suppliers provide technical support, helping businesses optimize adhesive use and troubleshoot issues, improving the efficiency of production processes.

- Sustainability and Compliance:A reliable supplier ensures that adhesives meet regulatory requirements and sustainability goals, enabling businesses to align with environmental standards and industry regulations.

Conclusion

One-part structural adhesives are integral to modern manufacturing and construction due to their strength, reliability, and ease of use. Choosing the right supplier is essential for ensuring product quality, performance, and adherence to industry standards. When selecting a supplier, it’s crucial to consider factors such as product range, technical support, sustainability, and supply chain reliability. A reliable supplier can provide high-quality adhesives, support efficient production processes, and contribute to long-lasting, durable applications across diverse industries. With the right supplier, businesses can enhance their competitive advantage, meet regulatory standards, and achieve superior results in their bonding applications.

For more about One-Part Structural Adhesives Supplier: A Comprehensive Guide, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.