Adhesive Manufacturing Companies: Overview, Market Trends, and Leading Players

Adhesive Manufacturing Companies: Overview, Market Trends, and Leading Players

Adhesives are vital in numerous industries, serving as essential materials in applications ranging from construction and automotive to electronics and packaging. Adhesive manufacturing companies are responsible for developing innovative bonding solutions that meet the diverse demands of these sectors. Over the years, advancements in adhesive technologies have spurred new products, improved environmental sustainability, and expanded market opportunities. This article provides a comprehensive overview of adhesive manufacturing companies, market trends, innovations, and the leading players in the industry.

The Role of Adhesive Manufacturing Companies

Adhesive manufacturers are crucial in developing products that provide bonding, sealing, and assembly functions across industries. Their offerings include a wide range of adhesive types, such as:

- Epoxy Adhesives: Known for their muscular bonding strength and chemical resistance, they are widely used in industrial applications, aerospace, and electronics.

- Acrylic Adhesives: These are valued for their versatility and quick bonding times. They are often used in automotive, medical device, and consumer goods manufacturing.

- Polyurethane Adhesives: With excellent flexibility and durability, polyurethane adhesives are commonly used in construction and furniture manufacturing.

- Hot-Melt Adhesives: Frequently used in packaging and textile industries, hot-melt adhesives offer fast bonding and are free of solvents.

Manufacturers are tasked with producing these adhesives and customizing them to meet specific industry requirements, ensuring the durability, strength, and environmental safety of their products. Developing new adhesive formulations is a crucial aspect of their innovation efforts, driving efficiency and enabling the growth of end-user industries.

Market Trends and Growth Factors

The adhesive manufacturing industry is continually evolving, influenced by global trends in technology, sustainability, and market demand. Several key trends and growth factors are shaping the industry:

Increasing Demand for Environmentally Friendly Adhesives

Environmental regulations and consumer awareness have pushed the adhesive industry toward developing eco-friendly, sustainable products. Solvent-based adhesives, which have traditionally been harmful to the environment due to volatile organic compounds (VOCs), are being replaced by water-based and solvent-free adhesives. Manufacturers are focusing on reducing the environmental footprint of their products by developing bio-based adhesives derived from renewable resources and recyclable formulations.

Growing Use of Adhesives in Automotive and Aerospace Industries

The automotive and aerospace industries are increasingly using adhesives in place of traditional mechanical fasteners like screws and bolts. Adhesives offer a lighter, cleaner, and more streamlined alternative, contributing to improved fuel efficiency and reduced vehicle weight. With the rise of electric vehicles (E.V.s), adhesive manufacturers are developing specialized solutions to meet the unique needs of battery assembly, ensuring thermal management, electrical insulation, and durability.

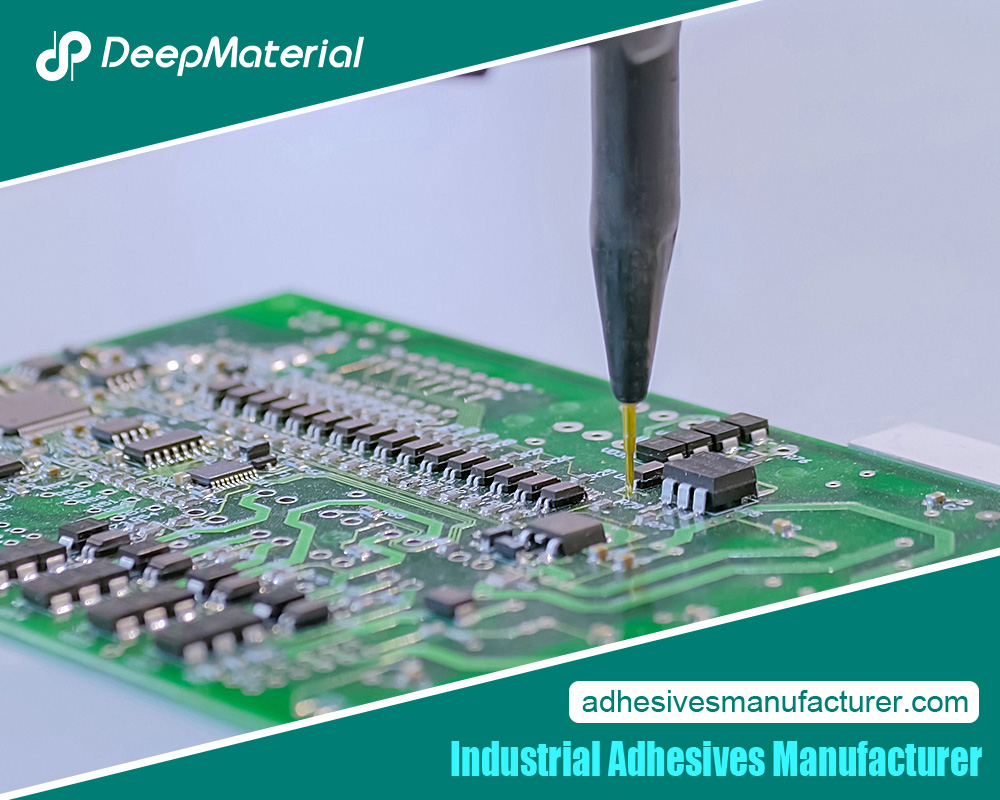

Rising Adoption in Electronics and Medical Devices

Adhesive manufacturers are experiencing growing demand from the electronics and medical device industries. In electronics, adhesives are essential for bonding components in devices such as smartphones, wearables, and computers. They are also used in flexible electronics requiring highly durable yet flexible adhesive materials. In medical applications, adhesives are used in devices such as bandages, surgical tapes, and medical sensors. The biocompatibility and sterilization capabilities of adhesives are vital in these applications.

Innovation in Smart Adhesives

Technological advancements are driving the development of intelligent adhesives that can sense changes in their environment, respond to stimuli, or offer self-healing properties. These adhesives are becoming increasingly crucial in high-tech sectors, including aerospace and defense. For instance, self-healing adhesives can repair minor cracks or damages, extending the lifespan of products and reducing maintenance costs. These innovations improve performance and open up new possibilities for adhesive applications.

Growth in E-Commerce and Packaging Industry

The rise of e-commerce has bolstered the demand for packaging adhesives. Packaging manufacturers rely on high-performance adhesives for cartons, labels, and shipping materials as online shopping increases. Adhesive manufacturers are responding by developing faster-curing and more robust products to meet the stringent requirements of this growing sector. Sustainable packaging, which often requires eco-friendly adhesives, is also gaining traction.

Leading Adhesive Manufacturing Companies

Several companies dominate the global adhesive manufacturing landscape, contributing to the industry’s innovations and advancements. Below is a list of some of the leading adhesive manufacturers:

Henkel AG & Co. KGaA

Henkel, a German multinational company, is a global leader in adhesives, sealants, and surface treatments. The company’s adhesive technology division offers solutions for automotive, electronics, construction, packaging, and more industries. Henkel is known for its Loctite brand, which provides a variety of high-performance adhesives, sealants, and coatings. Henkel strongly emphasizes sustainability, driving innovations in bio-based adhesives and solvent-free formulations.

3M Company

Headquartered in the United States, 3M is a diversified technology company that produces various products, including adhesives and tapes. 3 M’s adhesive offerings include solutions for automotive, aerospace, electronics, healthcare, and more. Their innovations focus on high-strength bonding, temperature resistance, and light-weighting, with popular products like the 3M VHB (Very High Bond) Tape. The company also emphasizes environmental sustainability by offering water-based and solvent-free adhesives.

H.B. Fuller

H.B. Fuller, another U.S.-based company, specializes in adhesives and sealants for various industries, such as construction, packaging, hygiene products, and electronics. Its portfolio includes products ranging from hot-melt adhesives to water-based and reactive adhesives. The company is known for its commitment to sustainability, offering green solutions like biodegradable adhesives and environmentally friendly bonding materials.

Sika AG

Swiss company Sika is a significant player in the adhesives and sealants market. Known primarily for its offerings in construction and industrial manufacturing, Sika produces a variety of adhesives, including structural adhesives for automotive and construction applications. The company’s SikaBond product line offers high-performance adhesives known for their bonding strength, flexibility, and resistance to environmental factors.

Bostik (Arkema Group)

Bostik, part of the Arkema Group, is a leading adhesive manufacturer offering solutions for the construction, automotive, aerospace, and packaging industries. Bostik is recognized for its Smart Adhesives, which focus on flexibility, adaptability, and sustainability. Their product offerings include various innovative adhesives, such as sealants, foams, and tapes, designed to meet the growing demand for eco-friendly and high-performance bonding solutions.

Avery Dennison Corporation

Avery Dennison, based in the U.S., is well-known for its adhesive materials and labeling solutions. The company specializes in pressure-sensitive adhesives used in packaging, labels, and graphics. Avery Dennison is committed to sustainability, producing environmentally friendly adhesive formulations, and developing new technologies that reduce waste and energy consumption.

Dow Inc.

Dow, an American multinational chemical company, offers adhesive solutions under its Dow Adhesives division. The company’s products serve various industries, including packaging, construction, and transportation. Dow is a pioneer in developing water-based and solvent-free adhesives that minimize environmental impact. Their innovation efforts focus on improving adhesive products’ performance, durability, and eco-friendliness.

Arkema S.A.

Arkema, a global chemicals and materials company based in France, produces adhesives under its Bostik brand. Arkema’s adhesive solutions are used in packaging, construction, automotive, and electronics applications. The company is focused on developing sustainable adhesive technologies, including bio-based adhesives and products that meet stringent environmental regulations.

Challenges Faced by Adhesive Manufacturers

Despite the growing demand and innovations in the adhesive manufacturing industry, companies face several challenges:

Raw Material Volatility

The adhesive industry relies heavily on raw materials like resins, chemicals, and solvents, many of which are derived from petrochemicals. Fluctuations in the prices and availability of these materials can impact production costs and profitability. Manufacturers increasingly seek alternative raw materials, such as bio-based products, to reduce reliance on fossil fuels.

Environmental Regulations

Adhesive manufacturing companies must adhere to strict environmental regulations, particularly regarding the emission of VOCs and the disposal of hazardous materials. Companies invest heavily in research and development to create solvent-free, eco-friendly products that meet regulatory standards without compromising performance.

Competition and Market Saturation

The adhesive market is highly competitive, with several large companies dominating the landscape. Smaller manufacturers must constantly innovate to differentiate themselves in a crowded market. Additionally, global economic fluctuations can impact demand, particularly in industries like construction and automotive, which are sensitive to economic cycles.

Conclusion

Adhesive manufacturing companies are at the forefront of material science, driving innovations that impact a wide range of industries. As sustainability, technology, and environmental consciousness become increasingly important, these companies are developing advanced adhesive solutions that meet the needs of modern applications. The future of the adhesive industry lies in eco-friendly products, high-performance bonding solutions, and innovations that will continue to shape industries worldwide. Leading players like Henkel, 3M, and H.B. Fuller will continue to guide the industry toward greater efficiency, sustainability, and technological advancement.

For more about a complete guide to the adhesive manufacturing companies: overview, market trends, and leading players, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.