Industrial Adhesive Manufacturers: A Comprehensive Guide

Industrial Adhesive Manufacturers: A Comprehensive Guide

In today’s manufacturing world, the role of adhesives has expanded well beyond simple bonding applications. Industrial adhesive manufacturers now offer specialized solutions for critical functions across multiple industries, including automotive, aerospace, electronics, construction, packaging, and more. With their ability to enhance production efficiency, improve product performance, and enable innovative designs, industrial adhesives have become indispensable in modern production lines.

This article explores the world of industrial adhesive manufacturers, detailing the types of adhesives they produce, their applications, the manufacturing processes involved, and the leading players in the market.

Types of Industrial Adhesives

Adhesives are formulated from various chemistries, each offering unique characteristics suitable for different applications. The major types of industrial adhesives include:

- Epoxy Adhesives

Epoxies are some of the most versatile adhesives used in electronics, automotive, and aerospace industries. Known for their excellent strength, durability, and chemical resistance, epoxy adhesives are widely used for bonding metals, plastics, and composites. They can withstand harsh environmental conditions and are typically used in applications where a high level of structural integrity is required.

- Acrylic Adhesives

Acrylic adhesives are known for their fast-curing properties and superior bonding strength to various materials, including metals, glass, plastics, and composites. Their high resistance to temperature, UV, and chemicals makes them suitable for outdoor applications and heavy-duty manufacturing. Acrylics are often used in automotive, signage, and general manufacturing industries.

- Polyurethane Adhesives

Polyurethane adhesives are flexible and resistant to moisture, making them ideal for applications that require some degree of movement or flexibility, such as in the construction and furniture industries. They provide strong adhesion to materials like wood, metal, and certain plastics and are commonly used in construction, packaging, and furniture manufacturing.

- Silicone Adhesives

Even at extreme temperatures, silicone adhesives are valued for their excellent thermal stability and flexibility. They are widely used in electronics, automotive, and aerospace applications where resistance to high heat, chemicals, and UV exposure is necessary. In critical environments, silicones are often chosen for sealing, gasketing, and bonding.

- Cyanoacrylate Adhesives

Commonly known as “super glue,” cyanoacrylate adhesives are known for their speedy curing times and intense bonds. They are used in various applications, from electronics assembly to medical devices. While they provide fast, strong bonding, they are best suited for smaller surface areas and lighter loads.

- Hot Melt Adhesives

Hot melt adhesives are thermoplastic substances that become liquid when heated and solidify upon cooling. They are widely used in packaging, bookbinding, and product assembly because they offer fast bonding times and are easy to apply. Hot melts are favored for their versatility and cost-effectiveness in large-scale production environments.

Applications of Industrial Adhesives

Applications of Industrial Adhesives

The versatility of industrial adhesives makes them suitable for various applications. Here are some of the key industries that rely heavily on adhesive technologies:

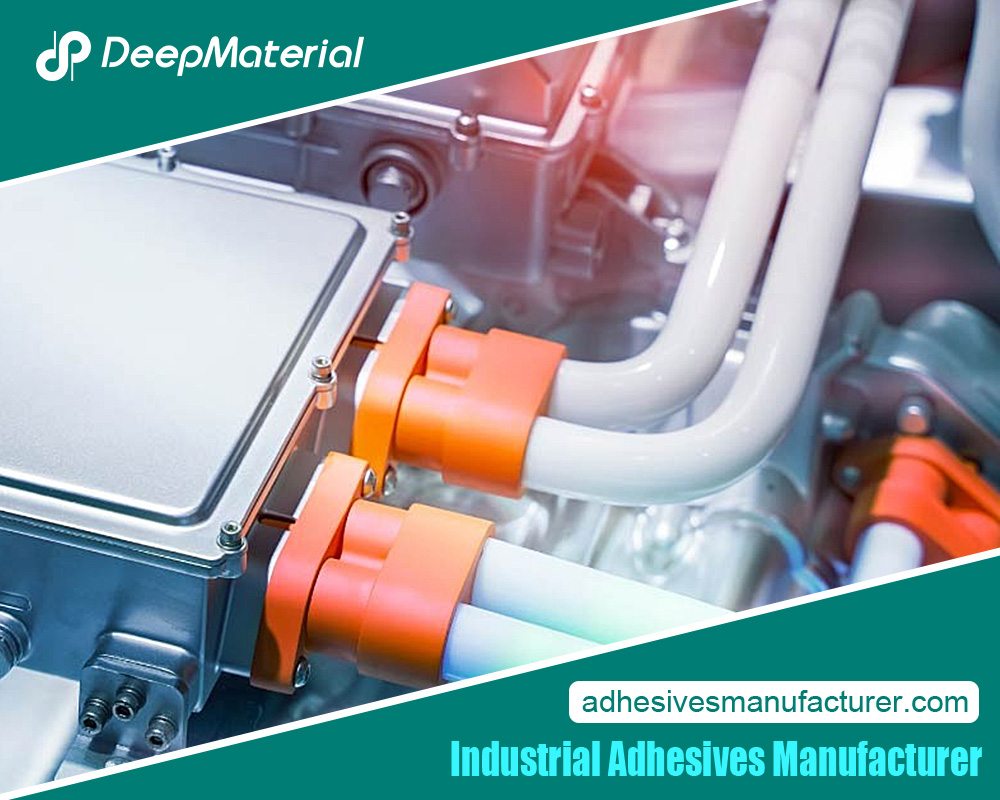

- Automotive and Transportation

Adhesives are used in everything from engine components and interior trim to exterior body panels in the automotive industry. They reduce vehicle weight by eliminating the need for heavy mechanical fasteners, improving fuel efficiency, and reducing emissions. Structural adhesives also enhance vehicle strength and crashworthiness.

- Electronics and Electrical

The electronics industry relies on adhesives for applications such as potting, encapsulation, and thermal management. Adhesives protect sensitive electronic components from moisture, dust, and mechanical stress. They are also used for bonding displays, assembling circuit boards, and securing batteries in electronic devices like smartphones, laptops, and electric vehicles.

- Aerospace and Aviation

Aerospace applications demand adhesives that can perform under extreme conditions, such as high temperatures and mechanical stress. This sector uses adhesives to assemble aircraft structures, including wings, fuselage panels, and interior components. These adhesives provide lightweight solutions while maintaining strength and durability.

- Construction and Infrastructure

Adhesives are used in the construction industry to bond tiles, flooring, windows, and insulation panels. They offer fast curing times and provide weather-resistant bonds that withstand the elements. Structural adhesives are often used in architectural designs to create clean, seamless joints in glass and metal structures.

- Packaging and Labeling

Adhesives play a crucial role in the packaging industry, where they seal cartons, label bottles, and assemble boxes. The fast-curing nature of hot melt adhesives makes them ideal for high-speed packaging lines, ensuring that products are securely sealed and labeled during distribution.

- Medical Devices

Adhesives used in the medical industry must meet stringent biocompatibility standards. They bond medical devices such as catheters, surgical instruments, and diagnostic equipment. Medical adhesives must also resist sterilization processes, such as autoclaving and radiation, without compromising bond integrity.

- Adhesive Manufacturing Processes

Industrial adhesive manufacturing involves complex chemical processes to ensure that adhesives meet specific performance criteria. Here are some standard manufacturing techniques used by adhesive manufacturers:

- Batch Processing

In batch processing, adhesives are produced in distinct batches, with each batch being mixed, heated, and cured according to specific formulations. This method allows manufacturers to maintain consistency across multiple batches and is often used for producing high-performance adhesives where precision is critical.

- Continuous Processing

Continuous processing is used for high-volume production, where raw materials are continuously fed into the manufacturing line, and adhesives are produced without interruption. This method efficiently produces large quantities of adhesives, such as hot melt or solvent-based adhesives.

- Emulsion Polymerization

Emulsion polymerization is a process used to create water-based adhesives by dispersing monomers in water with the help of surfactants. This process creates environmentally friendly adhesives with low VOC (volatile organic compound) emissions, making it ideal for packaging, paper, and textile applications.

- Solvent-Based Adhesive Manufacturing

Solvent-based adhesives are formulated by dissolving polymers in organic solvents. These adhesives provide excellent bonding strength and durability but release VOCs during application, making them less environmentally friendly. However, they are still widely used in industries like automotive and construction, where solid and durable bonds are essential.

- Hot Melt Adhesive Manufacturing

Hot melt adhesives are manufactured by blending thermoplastic resins, waxes, and other additives. The mixture is heated to create a molten adhesive, which is cooled and solidified. Due to their fast-setting properties, hot melt adhesives are widely used in packaging and product assembly.

Conclusion

Conclusion

Industrial adhesive manufacturers play a critical role in modern manufacturing, providing innovative bonding solutions that enable industries to produce lighter, more robust, and more durable products. From the automotive and aerospace sectors to electronics and packaging, adhesives are essential to countless applications. With advancements in adhesive technology and a growing focus on sustainability, the demand for high-performance adhesives continues to rise, driving growth and innovation in this dynamic industry.

For more about a complete guide to the industrial adhesive manufacturers: a comprehensive guide, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.