UV Curing Adhesives: The Game-Changing Technology Transforming Manufacturing

UV Curing Adhesives: The Game-Changing Technology Transforming Manufacturing

UV curing adhesives have emerged as a game-changing technology, transforming how manufacturers approach bonding, coating, and curing processes across various industries. These innovative adhesives harness the power of ultraviolet light to rapidly heal and form solid and durable bonds, offering advantages over traditional adhesive methods.

The Science Behind UV Curing Adhesives

At the heart of UV curing adhesives is a photochemical reaction triggered by exposure to UV light. When the adhesive is exposed to UV radiation, photoinitiators within the formulation absorb the energy and undergo a cleavage reaction, generating free radicals. These reactive species then rapidly polymerize, quickly transforming the liquid adhesive into a solid, cross-linked polymer network.

This curing mechanism is remarkably efficient. Depending on the intensity and wavelength of the UV light source, the adhesive can transition from a viscous liquid to a solid state in seconds. The ability to precisely control the curing kinetics by modulating the UV light parameters grants manufacturers unparalleled control over the bonding process, enabling them to tailor the adhesive’s properties to their specific needs.

Advantages of UV Curing Adhesives

The unique properties of UV-curing adhesives have made them a sought-after solution across a wide range of industries, from medical devices and electronics to automotive and packaging.

Rapid Curing and Increased Efficiency

One of the primary advantages of UV-curing adhesives is their lightning-fast curing time. Unlike traditional adhesives that rely on heat or chemical reactions, UV-cured adhesives can be cured almost instantly upon exposure to the appropriate UV light source. This rapid curing process allows manufacturers to significantly increase production throughput, reduce downtime, and streamline assembly lines.

Precise Control and Customization

The power to precisely control the curing process by manipulating UV light parameters empowers manufacturers to tailor the adhesive’s properties to their exact needs. This level of customization opens up possibilities for the development of adhesives with enhanced mechanical properties, improved resistance to environmental factors, and optimized compatibility with a wide range of substrates.

Environmental and Safety Benefits

UV-curing adhesives are not just efficient; they are also environmentally responsible. They are inherently more eco-friendly than their solvent-based counterparts, as they do not require volatile organic compounds (VOCs) or other hazardous chemicals. This reduces the manufacturing process’s environmental impact and enhances workplace safety by eliminating the need for specialized handling and storage of dangerous materials.

Versatility and Compatibility

UV-curing adhesives can be formulated to bond a wide range of materials, including glass, plastics, metals, and composites. This versatility makes them valuable assets in industries where the assembly of dissimilar materials is a common requirement, such as medical devices, electronics, and automotive components.

Applications of UV Curing Adhesives

The versatility and advantages of UV-curing adhesives have led to their widespread adoption across numerous industries, each with its unique set of challenges and requirements.

Medical and Dental Devices

The medical and dental industries have been at the forefront of the UV-curing adhesive revolution. These adhesives are prized for their ability to form solid and biocompatible bonds while withstanding the rigorous sterilization processes required for medical devices. UV curing technology has produced intricate, high-precision components for applications ranging from surgical tools to dental prosthetics.

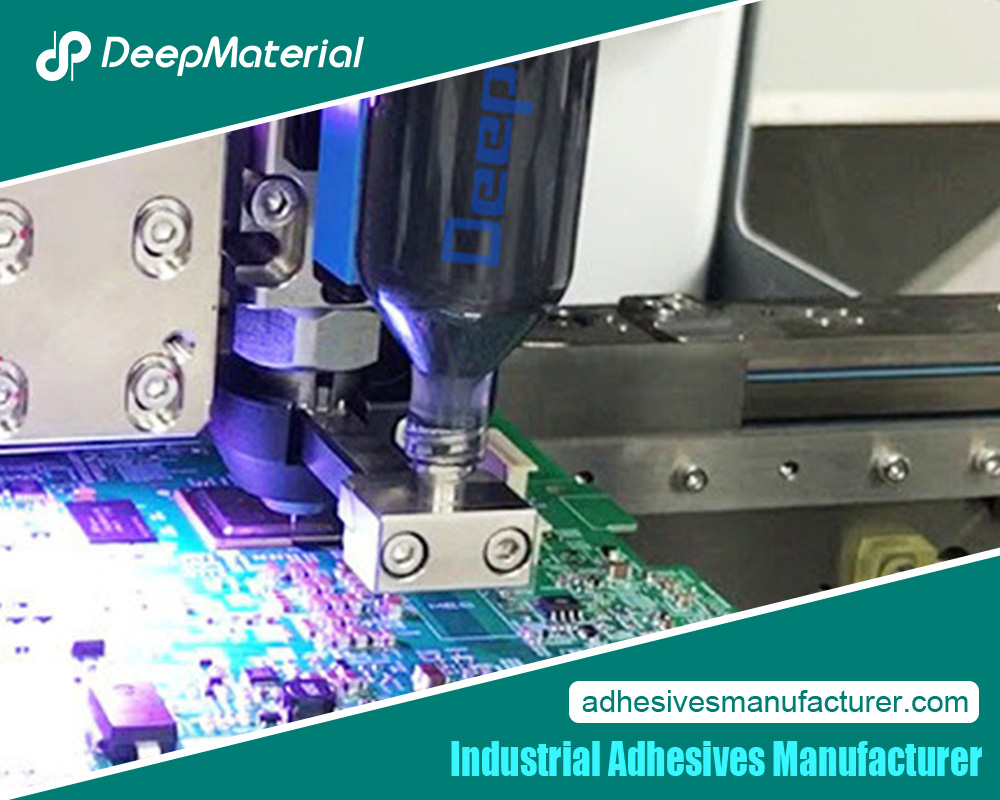

Electronics and Optoelectronics

In the fast-paced world of electronics and optoelectronics, UV-curing adhesives have become indispensable. Their rapid curing times, precise application, and ability to bond delicate components make them ideal for the assembly of microchips, displays, sensors, and other electronic devices. UV-curing adhesives also play a crucial role in the production of fiber optic cables, ensuring a tight, reliable seal during the assembly process.

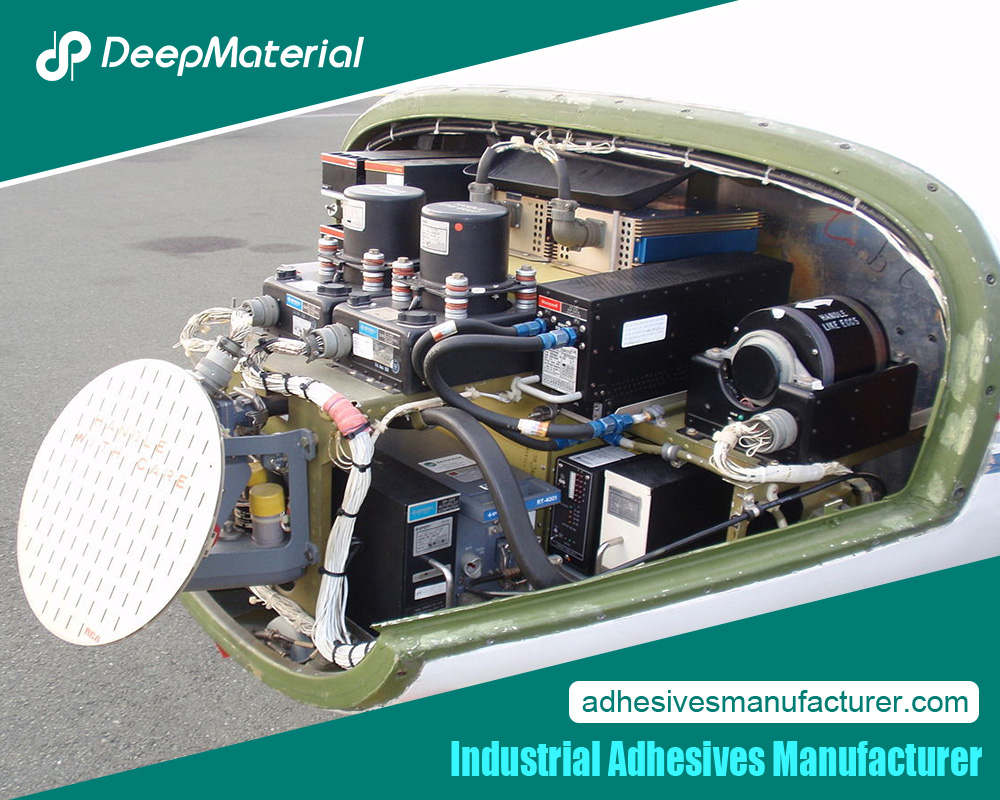

Automotive Industry

The automotive industry has embraced UV curing adhesives for their dual-purpose functionality, addressing structural and aesthetic requirements. These adhesives bond a variety of materials, from glass and plastics to metals, contributing to the lightweight design and structural integrity of modern vehicles. Additionally, UV-curing adhesives produce decorative elements, such as emblems and trim, providing a high-quality, durable finish.

Packaging and Labeling

The packaging and labeling industry has also benefited from adopting UV-curing adhesives. These adhesives offer rapid curing times, enabling high-speed production lines and reducing the risk of product contamination. UV-curing adhesives bond labels, inks, and varnishes to various substrates, including plastics, glass, and metals, ensuring a consistent, high-quality finish on different packaging materials.

The Future of UV Curing Adhesives

As the manufacturing landscape continues to evolve, the demand for innovative, efficient, and environmentally friendly solutions is expected to drive further advancements in the field of UV-curing adhesives. Industry experts foresee several key trends that will shape the future of this technology:

Increased Customization and Performance

Manufacturers will likely focus on developing even more customizable UV-curing adhesives, tailoring their formulations to meet the specific requirements of diverse applications. This may include creating adhesives with enhanced mechanical properties, improved resistance to environmental factors, and expanded compatibility with a wider range of substrates.

Sustainability and Eco-Friendliness

With a growing emphasis on sustainable manufacturing practices, the industry will likely see the development of UV-curing adhesives with improved environmental profiles. This may include the introduction of bio-based or biodegradable formulations, reducing the overall carbon footprint of the manufacturing process.

Advancements in Curing Techniques

Ongoing research and development will likely lead to further improvements in UV curing technology, such as faster curing times, deeper curing depths, and more efficient photoinitiators. These advancements will enable manufacturers to increase production speeds, improve reliability, and expand the range of applications for UV-curing adhesives.

Factors That Affect The Cost Of UV-curing Adhesives Include

The factors that affect the cost of UV-curing adhesives include:

Specialized Materials and Technology:

The manufacturing process for UV adhesives involves specialized materials such as photoinitiators and UV curing equipment, which can be expensive. These materials drive up production costs, contributing to UV adhesives’ higher upfront cost than traditional options.

Raw Material Costs:

Formulating UV-curable adhesives often requires specific raw materials, some of which may be costly or subject to price fluctuations. Specific photoinitiators and oligomers used in UV adhesive formulations can be expensive, increasing production expenses.

Production Expenses:

Using specialized equipment and technology to produce UV adhesives can lead to higher production expenses. Factors such as labor costs, energy consumption, and waste disposal can also impact the overall cost of manufacturing UV-curing adhesives.

Cost-Effectiveness of Alternatives:

Cost-Effectiveness of Alternatives:

Traditional adhesive options, such as solvent-based, water-based, and hot melt adhesives, are well-established and cost-effective solutions in many applications. The wide availability and lower cost of these alternatives may influence industries to stick with traditional adhesives rather than switching to UV-cured options.

UV-curing adhesives‘ versatility, efficiency, and environmental benefits will ensure their continued prominence across diverse industries as the manufacturing landscape continues to evolve. By harnessing the power of light, manufacturers can unlock new levels of productivity, quality, and sustainability, paving the way for a future where adhesives play an increasingly vital role in creating innovative, high-performance products.

For more about the UV curing adhesives: the game-changing technology transforming manufacturing, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.