The Benefits of Epoxy Powder Coating for Electrical Insulation

The Benefits of Epoxy Powder Coating for Electrical Insulation

Electrical insulation is a crucial aspect of any electrical system, as it helps to prevent electrical current from flowing where it shouldn’t and causing damage or accidents. Traditionally, insulation methods such as varnish and tape have been used to provide this protection. However, epoxy powder coating has emerged as a viable alternative that offers numerous advantages over these traditional methods.

In this post, we will look at how epoxy powder coating works as an insulator, its advantages over traditional insulation methods, its durability and longevity, its resistance to environmental factors and chemicals, its cost-effectiveness, ease of application and maintenance, compatibility with different types of electrical equipment, safety benefits, and potential future applications and developments.

How Epoxy Powder Coating Works as an Insulator

Epoxy powder coating is a type of coating that is applied to the surface of electrical equipment to provide insulation. It is made up of a mixture of epoxy resin and a curing agent, which when heated, forms a hard and durable protective layer. The chemical properties of epoxy powder coating make it an excellent insulator. It has high dielectric strength, which means it can withstand high voltages without breaking down.

It also has low electrical conductivity, which means it does not allow electrical current to flow through it easily. This combination of properties creates a barrier against electrical current, preventing it from reaching areas where it could cause damage or accidents.

Advantages of Epoxy Powder Coating over Traditional Insulation Methods

When compared to traditional insulation methods such as varnish and tape, epoxy powder coating offers several advantages. These will be discussed below for your understanding.

Durability and Longevity of Epoxy Powder Coating

One of the key advantages of epoxy powder coating is its durability and longevity. Unlike traditional insulation methods that may degrade or wear off over time, epoxy powder coating forms a hard and protective layer that can withstand wear and tear. This is especially important in industries where electrical equipment is exposed to harsh conditions or frequent movement.

For example, in the automotive industry, electrical components are subjected to vibrations, temperature fluctuations, and exposure to chemicals. Epoxy powder coating provides a long-lasting insulation solution that can withstand these conditions and ensure the reliable operation of the electrical system.

Resistance to Environmental Factors and Chemicals

Another advantage of epoxy powder coating is its resistance to environmental factors and chemicals. It is highly resistant to moisture, heat, and chemicals, making it suitable for use in a wide range of industries. In the automotive industry, for example, electrical components are often exposed to moisture and temperature fluctuations. Epoxy powder coating provides a protective barrier that prevents moisture from reaching the electrical components and causing damage.

It also protects against the corrosive effects of chemicals, ensuring the longevity of the electrical system. This resistance to environmental factors and chemicals makes epoxy powder coating an ideal choice for industries such as automotive, aerospace, marine, and oil and gas.

Cost-Effectiveness of Epoxy Powder Coating

While the initial cost of epoxy powder coating may be higher than traditional insulation methods such as varnish and tape, it offers significant cost savings in the long run. This is due to its durability and longevity. Epoxy powder coating forms a hard and protective layer that can withstand wear and tear over time. This means that it does not need to be replaced or repaired as frequently as traditional insulation methods.

Additionally, epoxy powder coating is resistant to environmental factors and chemicals, reducing the risk of damage to electrical equipment. This further contributes to its cost-effectiveness by minimizing the need for costly repairs or replacements.

Ease of Application and Maintenance

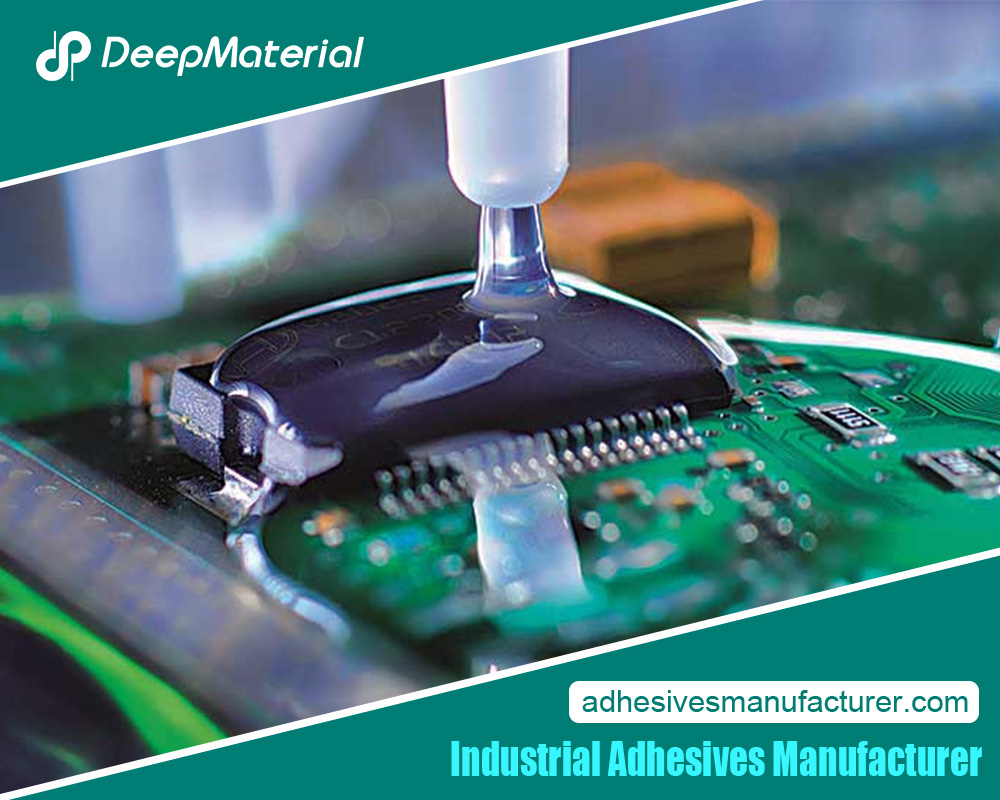

Epoxy powder coating is also known for its ease of application and maintenance. It can be applied to the surface of electrical equipment using various methods such as electrostatic fluidized bed, and electrostatic spray. Once applied, it cures quickly and forms a hard and durable protective layer. This ease of application makes epoxy powder coating a convenient choice for industries that require a fast and efficient insulation solution.

Also, epoxy powder coating is easy to maintain. It can be cleaned using mild detergents and water, and any damaged areas can be easily repaired by reapplying the coating. This ease of maintenance ensures the longevity of the electrical system and reduces downtime.

Compatibility with Different Types of Electrical Equipment

Epoxy powder coating is compatible with a wide range of electrical equipment, making it a versatile insulation method. It can be applied to various types of equipment, including motors, transformers, generators, and circuit boards. This compatibility makes epoxy powder coating suitable for use in a wide range of industries, including automotive, aerospace, marine, and electronics.

It also ensures that electrical equipment is adequately protected regardless of its size or complexity. This versatility makes epoxy powder coating a cost-effective and efficient insulation solution for industries that require insulation for different types of electrical equipment.

Safety Benefits of Epoxy Powder Coating for Electrical Insulation

Epoxy powder coating offers several safety benefits for electrical insulation. Firstly, it provides a barrier against electrical current, preventing it from reaching areas where it could cause damage or accidents. This reduces the risk of electrical shocks and fires, ensuring the safety of personnel and equipment.

Again, epoxy powder coating is resistant to environmental factors such as moisture and heat. This reduces the risk of electrical equipment malfunctioning or short-circuiting due to exposure to these factors. Overall, epoxy powder coating enhances the safety of electrical systems and helps to prevent accidents and damage.

Future Applications and Developments in Epoxy Powder Coating Technology for Electrical Insulation

The future of epoxy powder coating technology for electrical insulation looks promising, with potential applications and developments on the horizon. One potential application is in the renewable energy industry, where epoxy powder coating could be used to insulate solar panels and wind turbines. This would help to increase their efficiency and lifespan, as well as reduce maintenance costs.

Furthermore, there is ongoing research into the development of epoxy powder coatings with enhanced properties, such as increased thermal conductivity or self-healing capabilities. These developments could further improve the performance and durability of epoxy powder coating as an insulation method.

Conclusion

In conclusion, epoxy powder coating offers numerous advantages over traditional insulation methods for electrical insulation. Its chemical properties create a barrier against electrical current, ensuring the safety and reliability of electrical systems. It is more durable and long-lasting than traditional insulation methods, and it is resistant to environmental factors and chemicals. Epoxy powder coating is also cost-effective, easy to apply and maintain, and compatible with different types of electrical equipment.

For more about a complete guide to the benefits of epoxy powder coating for electrical insulation, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.